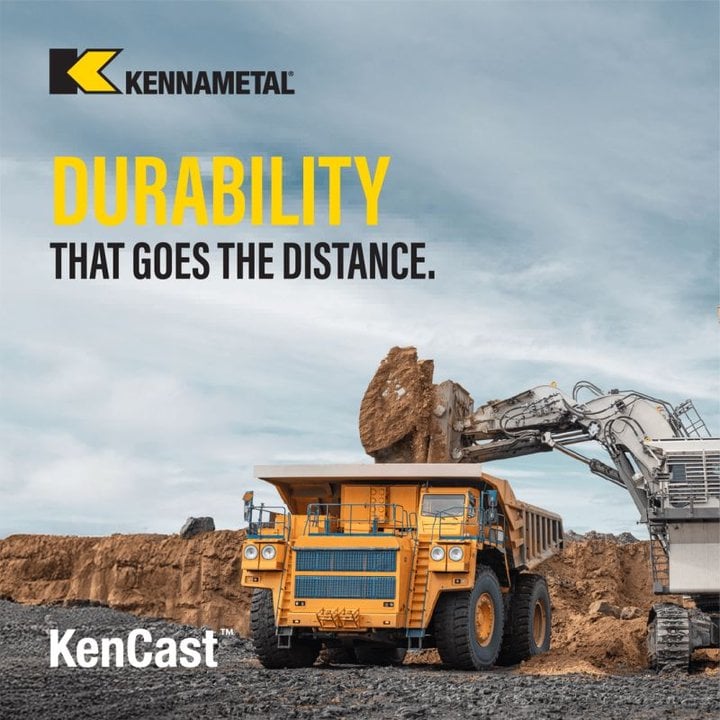

Manufacturing industry leader Kennametal has introduced an innovative solution for the wear and tear challenges faced in surface mining and earthworks. The company’s latest offering, KenCast™, addresses uneven wear by combining steel and tungsten carbide in a unique, non-layered structure. This design enables enhanced durability by focusing protection on specific zones where wear is most prevalent.

Traditional protection methods often distribute materials evenly across the surface, leading to inefficiencies and material waste in areas less prone to wear. KenCast™ counters this by strategically placing the robust composite material only where it’s genuinely needed. This targeted approach not only extends the service life of equipment but also optimizes costs by reducing unnecessary material use.

The development of KenCast™ signifies a significant advancement in the materials engineering domain, opening new avenues for prolonged equipment lifespan and operational efficiency. By understanding the specific zones affected by wear, Kennametal effectively increases productivity and reduces downtime for its clients in the mining and earthworks sectors.

Founded in 1938, Kennametal has continuously pioneered solutions in the industrial realm, gaining a reputation for its innovation and customer-centric approach. They continue to be a leader in materials science, providing essential products catering to various industries. KenCast™ is a testament to the company’s commitment to driving innovation and offering tangible benefits to the global mining industry.

View more news from Kennametal