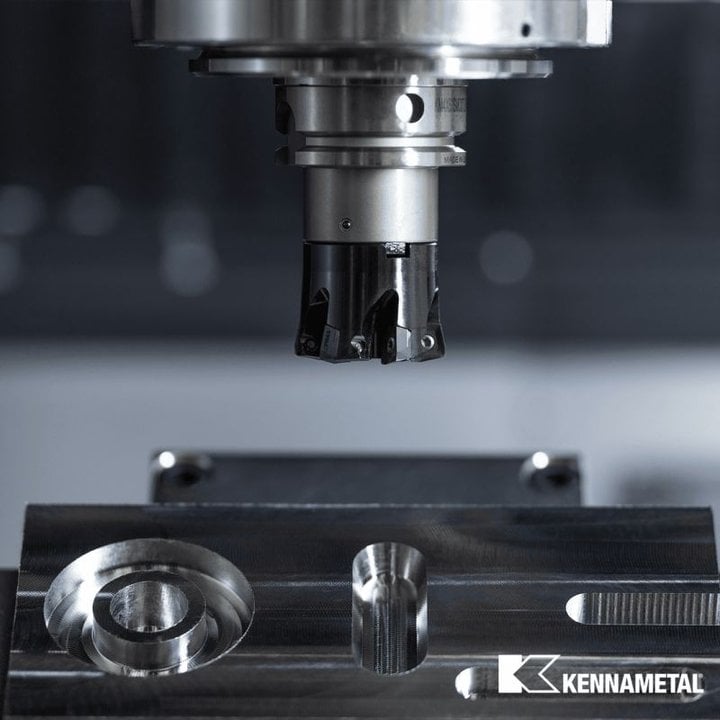

In a significant advancement for the composite machining industry, ROCO™ has unveiled its latest high-performance composite routing tools. These routers, featuring the newly developed KCC05A coating, are designed to deliver sharper edges and superior wear resistance, effectively extending the lifespan of machining tools.

The KCC05A coating is key to this innovation, providing enhanced durability and performance. By reducing wear and tear, these routers are poised to become essential tools for businesses focused on high-performance composite routing.

Composite materials, known for their strength and lightweight properties, are widely used across various industries including aerospace, automotive, and renewable energy. The introduction of ROCO™ routers aims to improve the efficiency and effectiveness of machining processes, benefiting manufacturers in these sectors.

By offering enhanced edge sharpness and longer tool life, the new routers from ROCO™ are expected to reduce operational costs and downtime, enabling manufacturers to maintain high levels of productivity. This development is particularly crucial for industries where precision and quality are paramount.

As manufacturers continuously seek to enhance their processes and performances, the ROCO™ composite routers are likely to play a pivotal role in meeting these demands. The innovation reflects ROCO™’s commitment to providing cutting-edge solutions tailored to the specific needs of the manufacturing sector.

The company behind these advancements, 1445 Corporation, is well-positioned in the market with a reputation for developing reliable and innovative industrial tools. Their focus on technology-driven solutions helps them maintain a competitive edge and cater to a diverse range of industrial requirements.

Read this post on LinkedIn