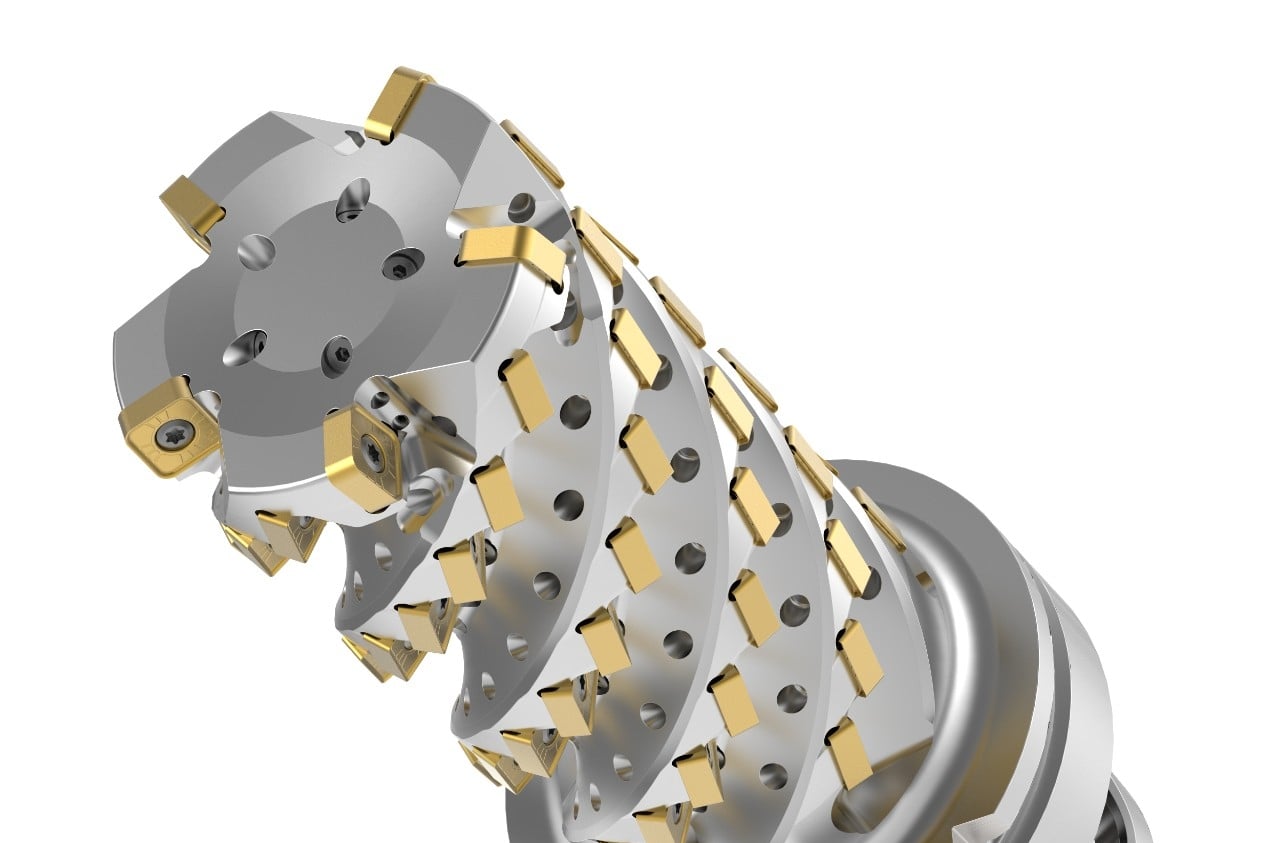

Kennametal has now introduced its latest helical milling series, the HARVI Ultra 8X. With up to 8 cutting edges per insert, the new HARVI Ultra 8X provideshelical milling at the lowest possible cost-per-edge.

The innovative new HARVI Ultra 8X helical milling cutters have been designed to deliver the highest metal removal rates (MRR), especially when machining high-temperature alloys. The exciting new HARVI Ultra 8X is offered with lead inserts in various corner radii to meet the needs of the aerospace industry. This makes the HARVI Ultra 8X particularly suitable for machining airframe structural parts.

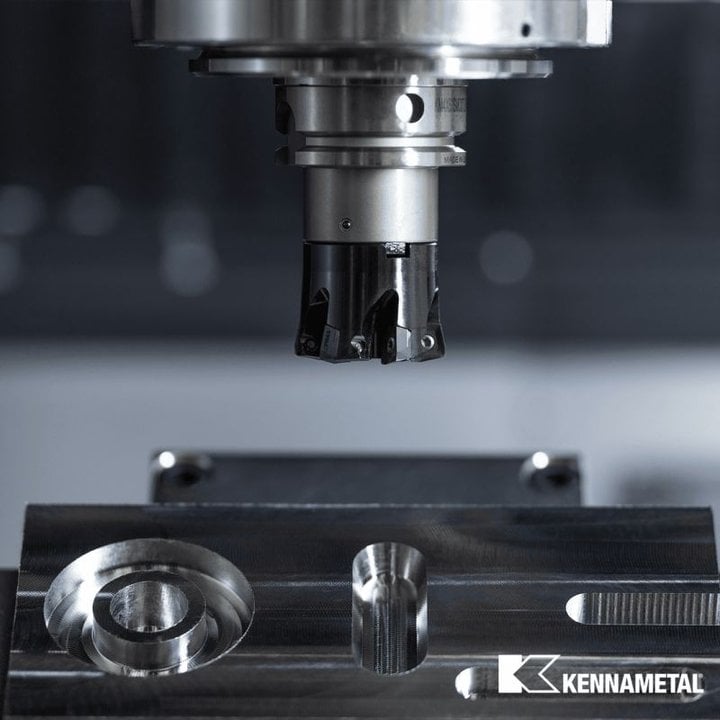

The development of the new range sees the HARVI Ultra 8X incorporate a series of taper flange adapters to achieve maximum tool stiffness and maximum tool life whilst adjustable coolant nozzles support chip evacuation and control heat in the cutting zone, allowing application specific coolant flow management.

With a large helix angle, the new range ensures hassle-free chip evacuation even at the highest metal removal rate applications. This is underpinned by the KM4X™ that provides the most rigid spindle connection in the industry. Working in synergy with the taper flange design provides higher stability than straight flanges and adds bending moment resistance to enhance performance. With a selection of insert designations and toolholders – this is definitely worth looking at…