As a global leader in premium high-precision tooling systems, BIG KAISER has developed the new Dyna Test precision inspection test bar system for monitoring spindle performance – a system that is now available from the Tamworth cutting tool experts at ITC.

Undertaking regular inspections with the new Dyna Test bar can identify potential problems with spindles and bearings to reduce costly downtime and lost production as well as avoiding expensive repairs. When machine spindle damage is not detected at an early stage, it can evolve into a more serious issue that will have a major impact on machining operations, potentially causing product rejections and excessive tool wear.

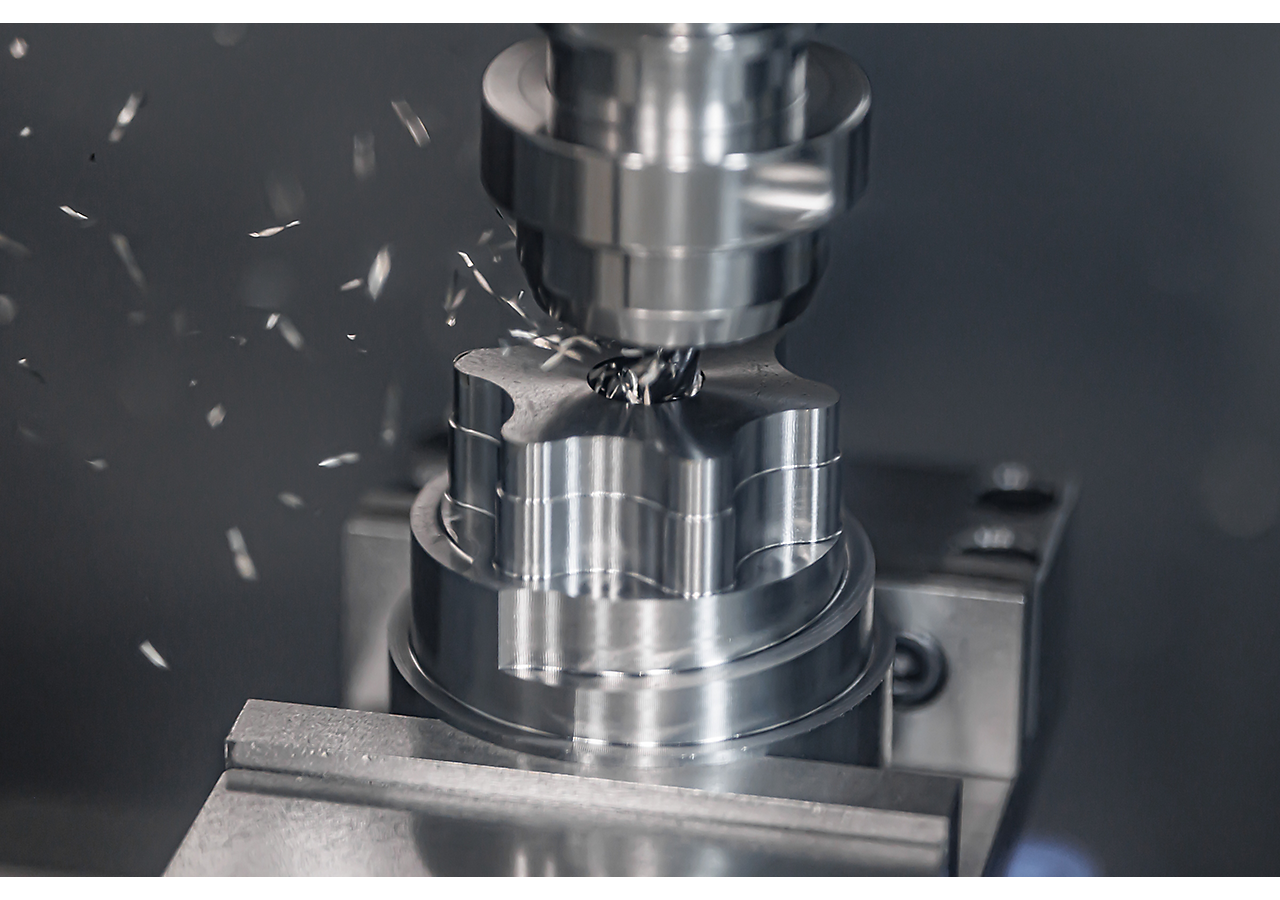

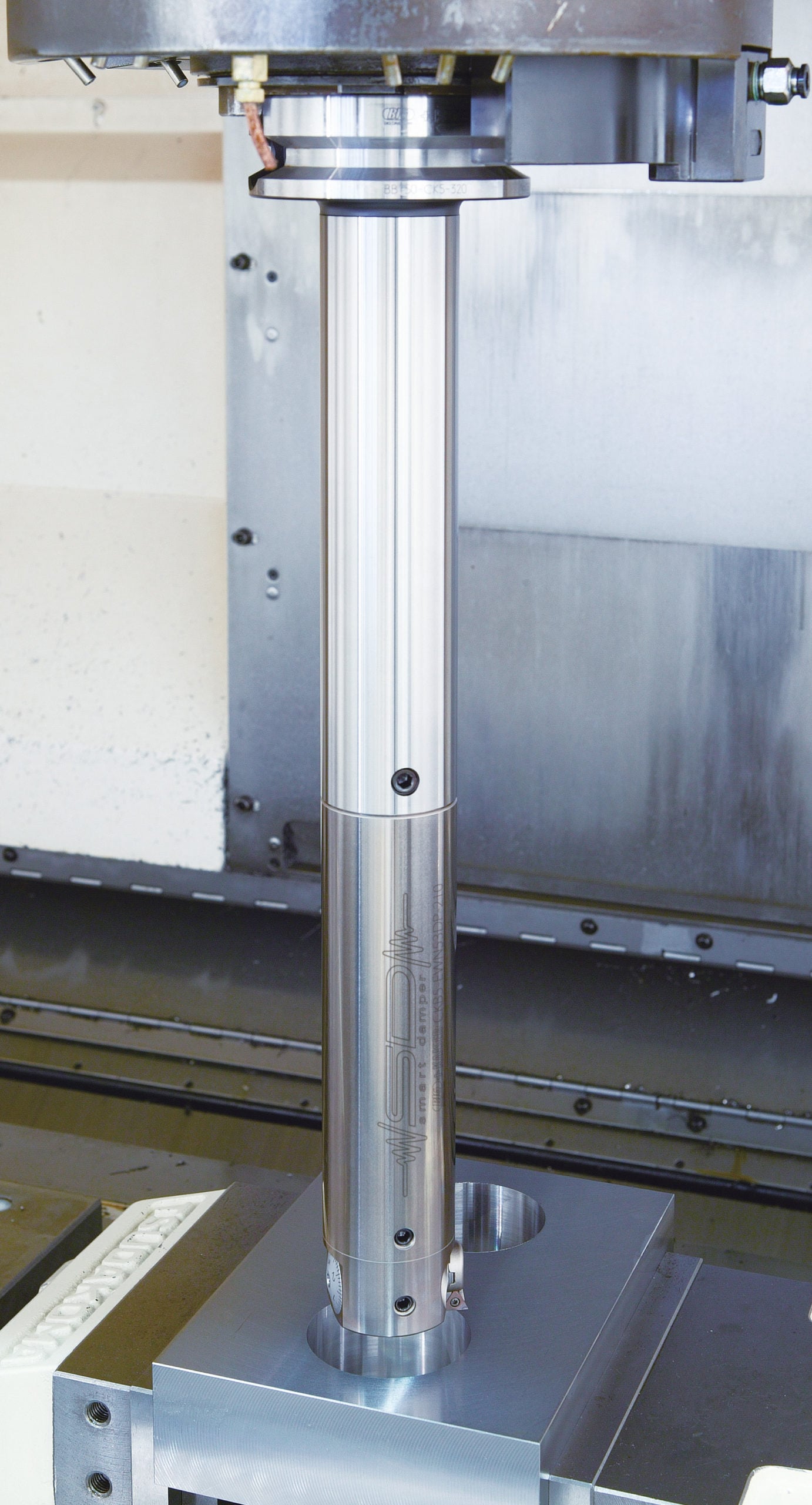

When used, the Dyna Test device is clamped in the machine spindle and then rotated. A dial gauge measures the deflection of the test mandrel, checking the concentricity of the spindle. While this test can be performed with a tool to identify concentricity inaccuracies, it is still necessary to determine whether the problem is caused by the spindle, the shank or the tool itself. The Dyna Test bar identifies spindle inaccuracies immediately, eliminating all other variables.

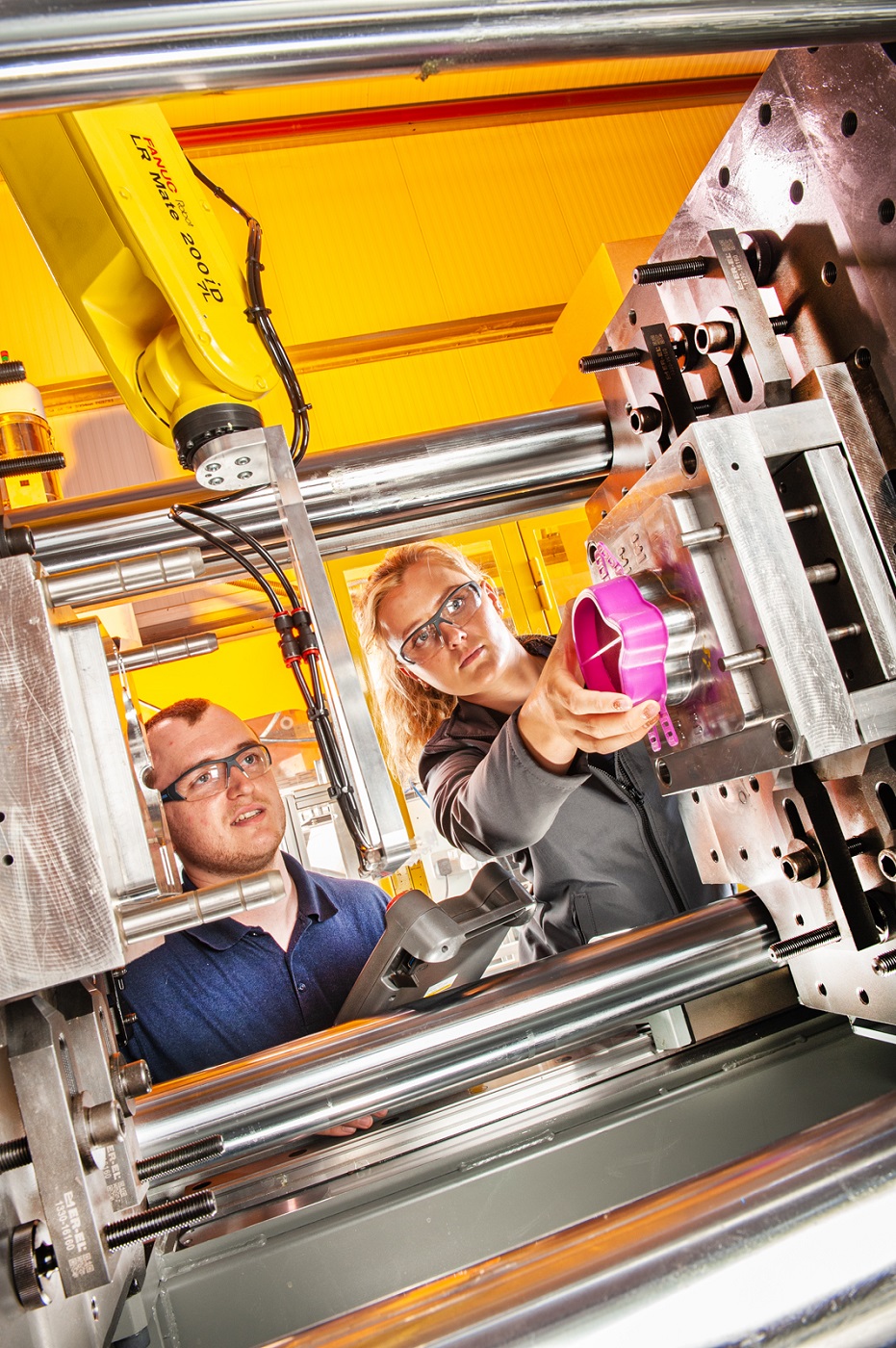

To meet the requirements of ISO: 9000, BIG KAISER can provide a calibration certificate with complete traceability upon request. To ensure the highest possible precision levels are met, all Dyna Test bars are produced under an extremely strict quality control system. ITC can now offer the Dyna Test bars for BBT, BDV, HSK and BIG CAPTO configured spindles. The test bars are protected in a sturdy aluminium storage case to prevent damage. Both ITC and BIG KAISER strongly believe that smooth interaction between all components in the machine tool is essential for achieving superior-quality machining results.

Customers are thus encouraged to utilise the company’s precise machine testing equipment, which, when used regularly for inspection of machine tools, can reliably prevent damage and noticeably improve process reliability. For further information on how you can prolong the life of your machine spindle and reduce costly downtime and repairs, please contact ITC via www.itc-ltd.co.uk for more information.