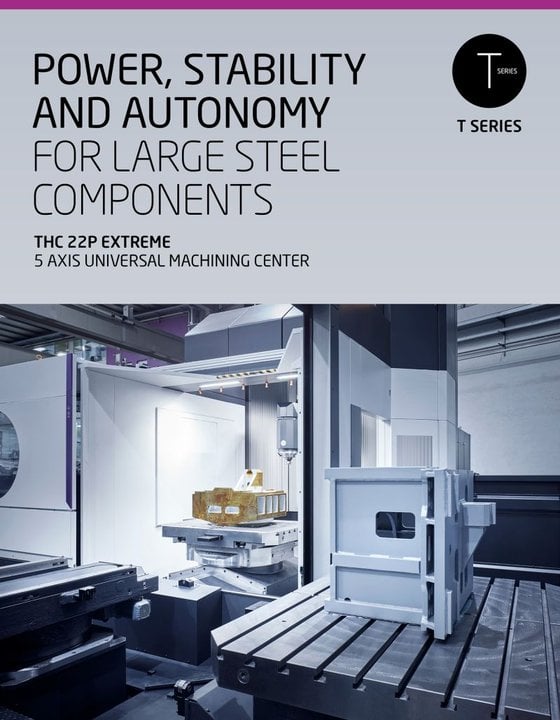

IBARMIA has introduced the THC 22P EXTREME, a cutting-edge 5-axis machining center designed to optimize manufacturing with reduced setups and enhanced control over long cycle processes on large steel components. This machine represents a significant advancement in manufacturing technology, catering to industries where precision and efficiency are paramount.

The THC 22P EXTREME is engineered for superior performance, featuring an expansive operational reach with dimensions measuring X=2200 mm, Y=1600 mm, and Z=1900 mm. Its versatile B-axis allows for movement from -15° to +195°, enabling intricate machining work in a single clamping.

Powering the machine is the robust HSK A100 spindle, capable of reaching up to 12000 rpm. It delivers 48 kW at 1500 rpm and increases to 74 kW at 4000 rpm. This is complemented by a substantial 240-tool magazine and dry machining capacity, enhancing operational capability and turnaround.

Automation is a key factor in the THC 22P EXTREME’s design philosophy. The machine is equipped with an IBARMIA palletised rotary table that can handle loads up to 10000 kg, supported by a T22 pallet pool. This arrangement ensures a seamless flow of parts, maintaining consistent processing and maximizing spindle uptime.

IBARMIA continues to innovate within the manufacturing sector, with the THC 22P EXTREME set to provide new efficiencies and capabilities for industrial applications. The machine reinforces IBARMIA’s position as a leader in advanced machine tool solutions, satisfying the demanding needs of modern manufacturing.

View more news from IBARMIA