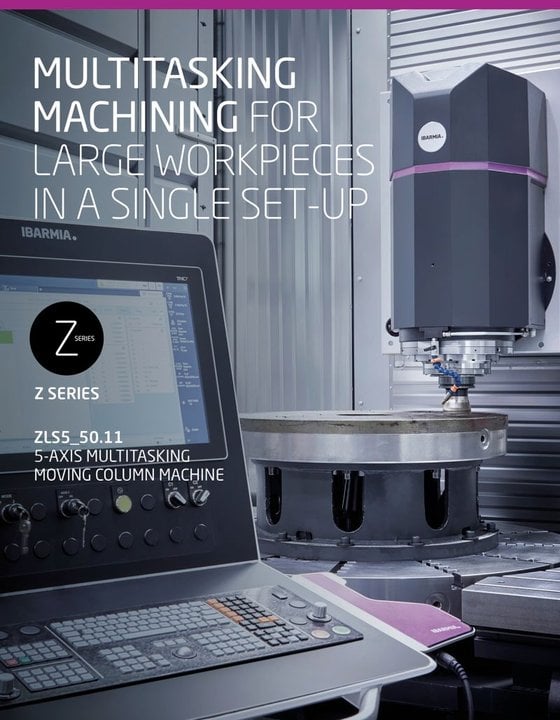

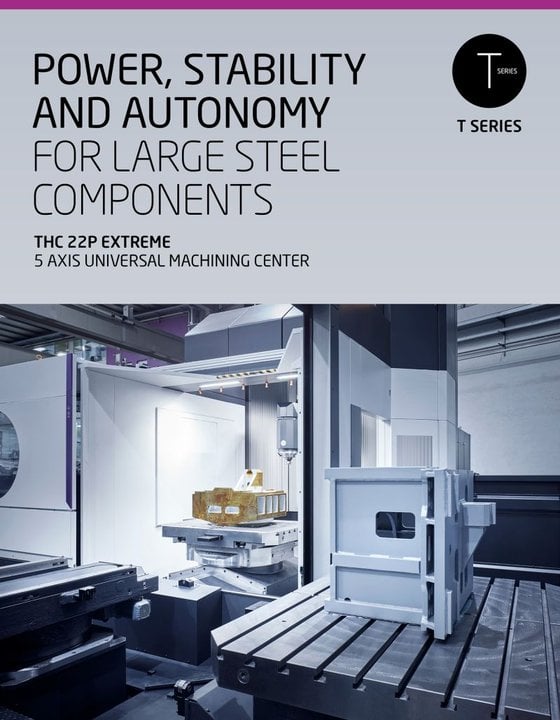

IBARMIA, a leader in machine tool innovation, has unveiled advancements designed to meet the demanding needs of capital goods production. Companies within the textile, paper, and packaging sectors require machines offering both precision and versatility for machining large structures and functional components. IBARMIA addresses these requirements with its configurable 5-axis and multiprocess platforms.

The company’s machines boast features such as long travels, moving tables, and pendulum setups. These configurations are essential for maintaining high surface quality and geometric stability, crucial for industries reliant on large-scale components. IBARMIA further enhances productivity with seamless automation solutions, including pallet pools and FASTEMS cells, enabling continuous 24/7 operations.

Recent projects by IBARMIA include collaborations with industry giants like ANDRITZ and Picanol Weaving Machines. These partnerships highlight the company’s commitment to delivering innovative solutions that cater to specific industry needs. By providing advanced machinery capable of handling complex, large-scale parts, IBARMIA positions itself at the forefront of manufacturing technology.

The developments by IBARMIA reflect a significant stride in the production capabilities of machine builders across various sectors. With technology that ensures precision and efficiency, the company continues to support and drive the capital goods segment toward future growth and innovation.

Read this post on LinkedIn