In the opinion of Hurco Europe, one of the exhibitors at this year’s Southern Manufacturing & Electronics exhibition, held from 7th to 9th February 2023 at the Farnborough International Exhibition Centre, the show certainly delivered in terms of visitor footfall and customer enquiries.

Celebrating its 25th anniversary this year, Southern Manufacturing was a record-breaker in terms of attendance, with 9,144 visitors welcomed through the doors, according to the organisers. The increase in footfall was reflected in people coming on to the Hurco stand. More than 80 enquiries were booked over the three days, of which 20 percent were new contacts.

David Waghorn, managing director of Hurco Europe said, “In a non-MACH year especially, Southern is proving to be a significant event for UK manufacturing industry. Recent improvements to the road access and venue have guaranteed a better experience for exhibitors and visitors alike. We had no hesitation in rebooking the same space for 2024.”

Many attendees from Hurco’s existing customer base were keen to see the latest WinMax features that simplify programming, such as the Solid Model Import option that allows a user to create a program at the control, directly from an STP file with no need for CADCAM.

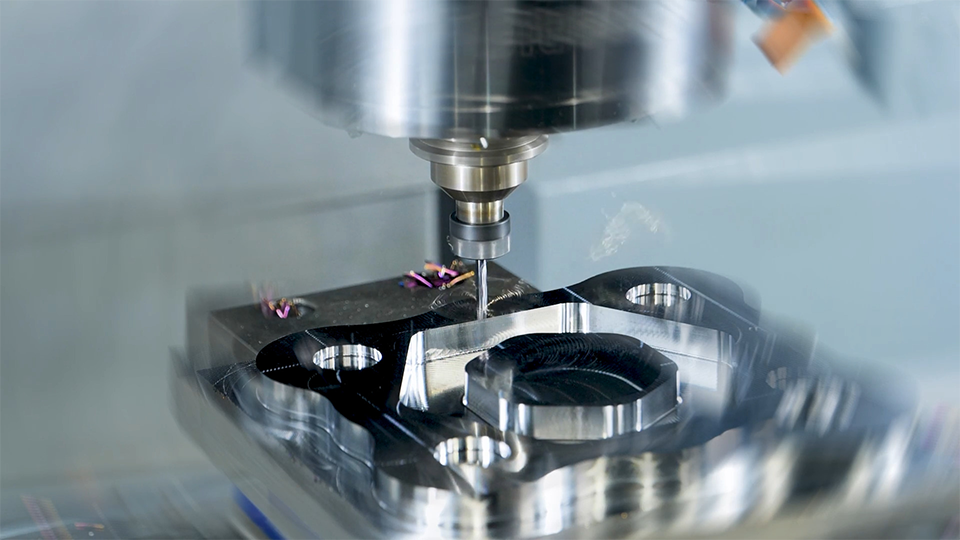

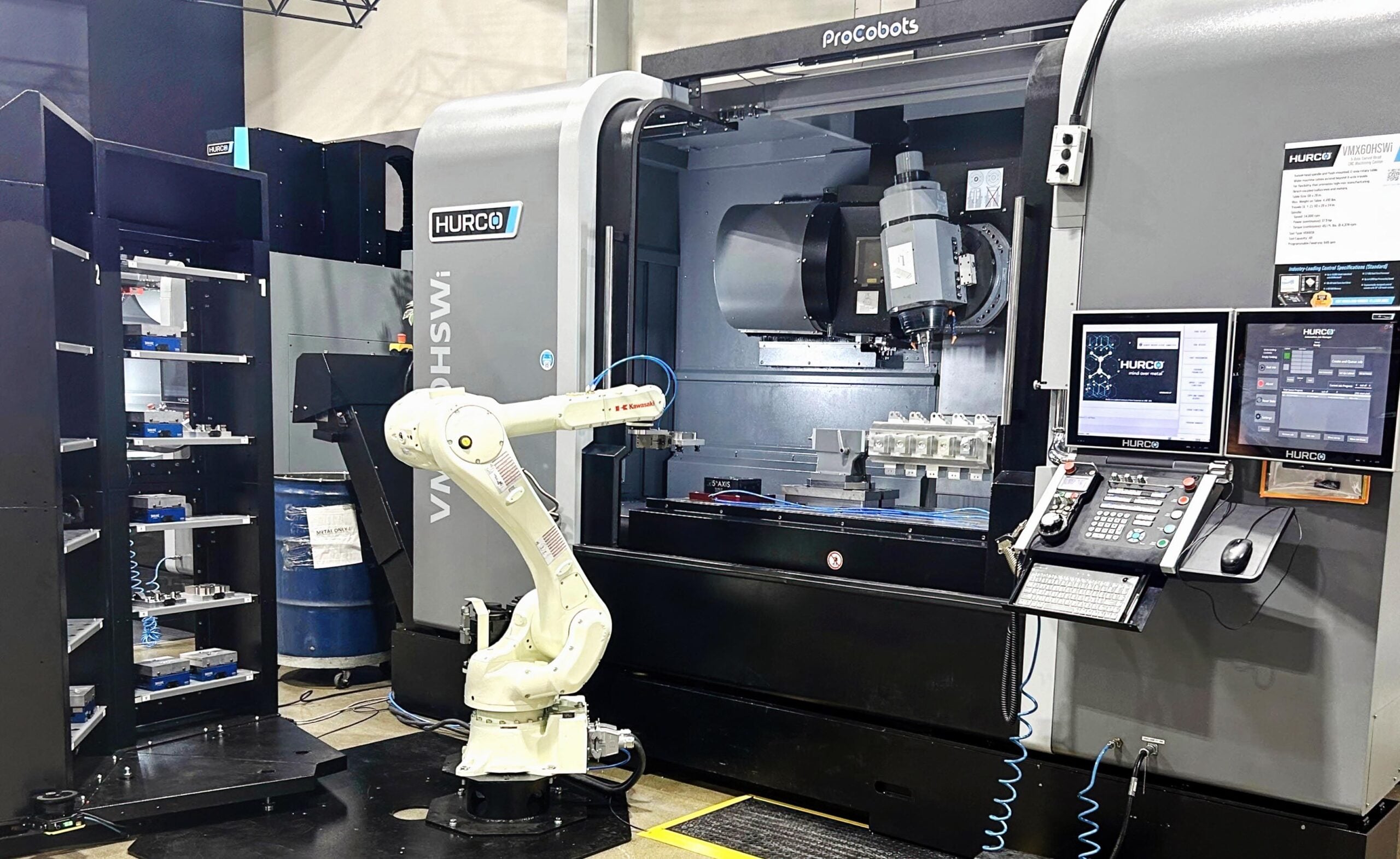

The VM10i compact, 3-axis machining centre on show was a major attraction due to its ability to deliver true machining centre performance in a compact footprint. Steel cutting demonstrations took place throughout the show. Popular with small volume parts makers, toolmakers and prototyping shops, the machine boasts a 10,000 rpm SK or BT spindle, 660 x 406 x 508 mm travels and a 24 station swing-arm toolchanger.

On show also was the TM6i XP 2-axis CNC lathe for chucking up to 316 mm diameter or turning parts up to 45 mm in diameter from bar. The performance of this compact, accurate turning machine was complemented by the Max5 control, with its easy-to-follow graphics for guiding the user through tooling selection and all operations. The XP suffix denotes the inclusion of enhancements such as concurrent programming, improved graphics and roller guideways as standard.

Mr Waghorn added, “Machine tool delivery lead-times within the industry are generally quite long at the moment, but we are fortunate to have VM10i machines available ex stock. I would encourage our new contacts from the show as well as existing customers to take advantage of the Government’s super-deduction corporation tax offering for machines delivered before 31st March 2023.”