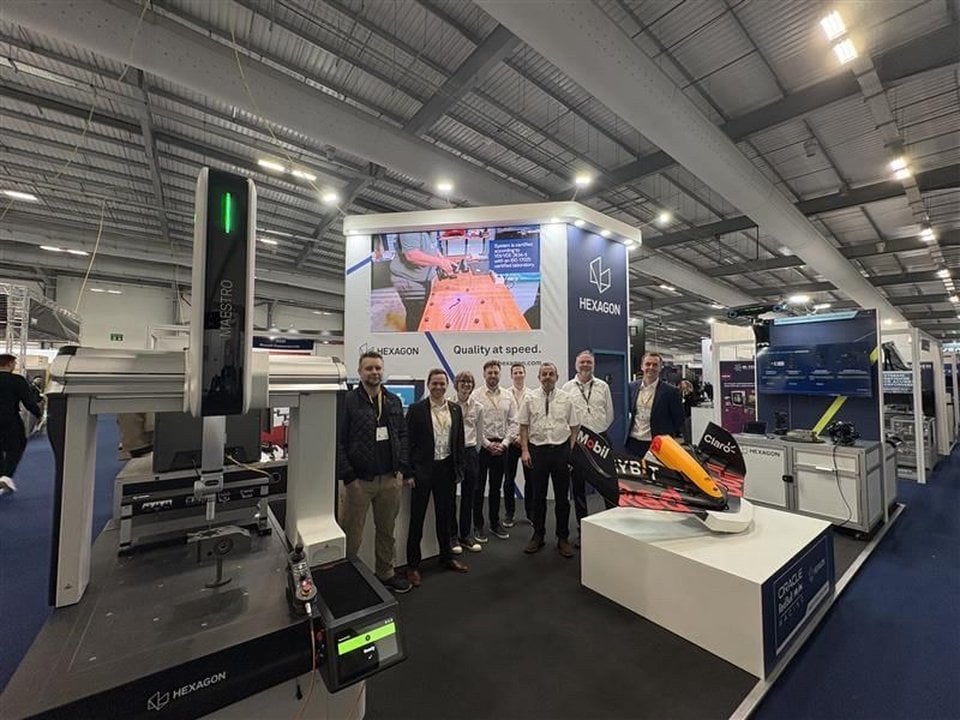

Transforming quality inspection with high-speed, connected measurement workflows, Hexagon’s Manufacturing Intelligence division has announced the launch of MAESTRO, an all-new, next-generation coordinate measuring machine (CMM) engineered from the ground up to meet the rising productivity demands of modern manufacturing. Designed to address global skills shortages and increasing quality requirements, MAESTRO sets a new standard for speed, simplicity, and digital integration in metrology.

Building on Hexagon’s heritage of metrology excellence, MAESTRO is based on four principles: speed, ease of use, connectivity, and scalability. Its digital-first architecture provides the industry with rapid measurement routines, an intuitive user experience, and seamless data integration. With modular software and hardware, it is designed to adapt to evolving production needs, making it ideal for aerospace, automotive, and high-precision manufacturing environments where there is a strong demand for accuracy to ensure safety, compliance, and performance.

Building on Hexagon’s extensive global metrology expertise, MAESTRO features a newly developed digital architecture that incorporates digital sensors, a single cable system, and a completely new controller with brand new firmware. Together, these capabilities increase throughput, streamline the entire measurement operation, and ensure future-ready connectivity for modern production environments.

Customers will benefit from:

- Unmatched precision at speed: MAESTRO’s redesigned mechanical structure, single-cable digital platform, and advanced sensors enable fast measurement with sub-micron tolerances that meet stringent industry standards. Customers gain the confidence of repeatable, certified measurements for critical quality control. This ensures reliable results, even for complex shapes and the most demanding applications.

- ◦ Breakthrough speed: MAESTRO delivers industry-leading throughput through high-speed motion while maintaining exceptional precision. Synchronised axis movements, rapid calibration, and cloud-connected software significantly accelerate setup, programming, execution, and reporting.

- ◦ Simpler use and programming: MAESTRO transforms quality inspection by simplifying CMM programming and streamlining workflows. An intuitive user interface, along with next-generation cloud-native metrology apps powered by Hexagon’s Nexus platform, enables both expert metrologists and less-specialised staff to generate repeatable, standard-compliant measurements effortlessly, without the need for coding.

- ◦ End-to-end connectivity: Designed as an Industrial Internet of Things (IIoT) native measuring device, MAESTRO integrates into Hexagon’s Nexus ecosystem, sharing real-time data across design, production, and quality teams. This drives data-driven decision-making and improves overall equipment effectiveness (OEE). Near-line or inline integration with automation systems is seamless.

- ◦ Scalable platform: With a modular design and a robust roadmap for future upgrades, MAESTRO is built for scalability. Manufacturers can easily update software, sensors, and additional capabilities over time, ensuring that their investment remains future-proof and continuously supports evolving production needs.

“Manufacturers told us they needed a next-generation system that tackles rising quality demands and skills shortages,” said Jörg Deller, General Manager Stationary Metrology devices at Hexagon. “By rethinking our hardware and software from the ground up, rather than iterating on existing systems, we’ve had the freedom to create a high-accuracy inspection solution that is so intuitive that anyone from expert to new hires become significantly more productive. Meeting the needs of industry head-on, MAESTRO’s digital backbone also makes it straightforward to integrate into modern connected factories, so stakeholders can improve quality quickly and definitively.”

Pilot users report significant productivity gains and shorter inspection lead times, helping to prevent production bottlenecks and keep up with rapidly changing customer requirements. Customers have tested various sensors, ranging from high-speed laser scanning to tactile probes, achieving consistently strong results in both R&D and production applications.

Hexagon’s software tools and services, including PC-DMIS, the Metrology Mentor, Metrology Asset Manager, and Metrology Reporting Nexus Apps, were developed alongside MAESTRO to create an integrated system that significantly enhances productivity from part loading to analysis, compared to isolated component solutions. The end goal is to provide ease of use and fast workflows, from programming and execution to reporting and collaboration with colleagues in design and manufacturing.

MAESTRO will be offered initially in various sizes and configurations, each engineered for automated multi-sensor workflows utilising tactile probes and laser scanning probes from a new “digital rack” that monitors occupancy status and sensor health. This information can be accessed on-device and through desktop and cloud-native apps. Additional future-ready models and enhancements will follow, all based on a single, coherent platform.

MAESTRO will be available for order from 30 June 2025. For additional specifications, demos, and pricing, please contact your local Hexagon representative or visit https://hexagon.com/products/maestro