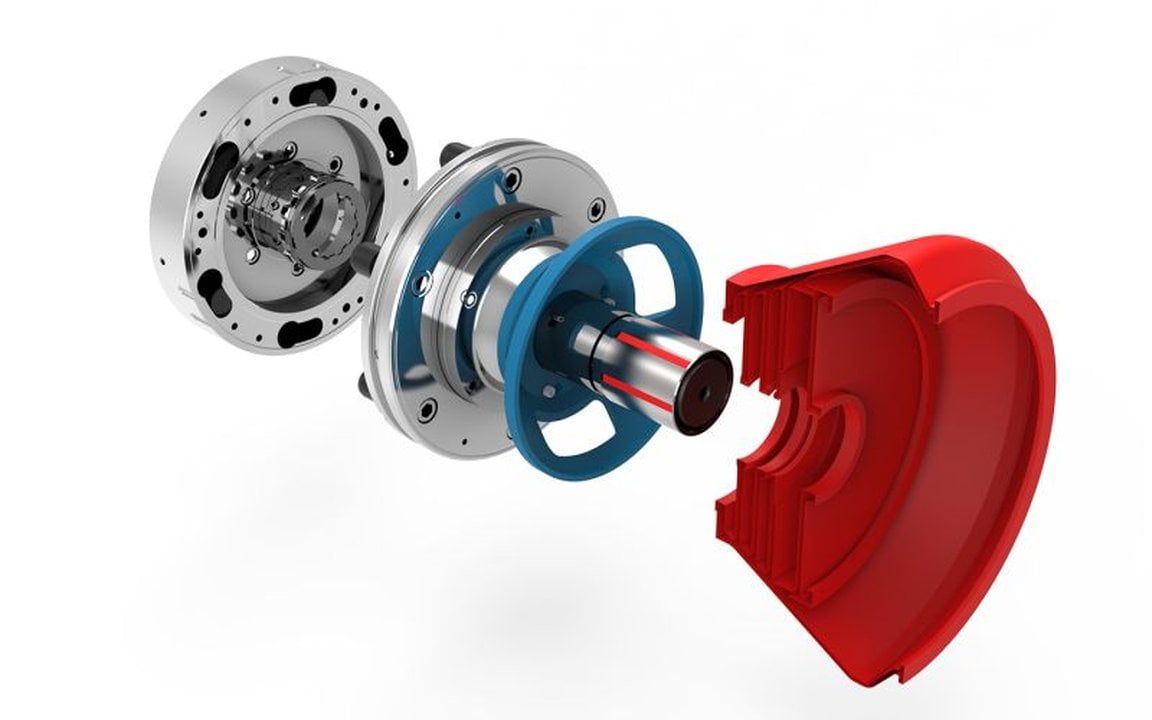

HAINBUCH America Corporation has introduced centroteX, a revolutionary solution designed for modern machine shops dealing with shorter runs and more frequent changeovers. With precision levels achieving an accuracy of less than three microns, centroteX allows manufacturers to switch between jobs with remarkable speed and confidence, ensuring that the first part is always within specification.

The centroteX system is especially beneficial for CNC machining and metalworking environments where precision and efficiency are crucial. By significantly reducing setup times, it enhances productivity and ensures enhanced operational flexibility. This solution arrives at a crucial time for the manufacturing industry, where demand for quick adaptability and precision is at an all-time high.

The ability of centroteX to maintain high accuracy without requiring manual indication sets it apart from traditional systems. It empowers machine shops to maintain consistent quality, thus reducing wastage and improving overall output. As industries increasingly shift towards manufacturing custom or small batch parts, the demand for solutions like centroteX is expected to rise considerably.

Based in North America, HAINBUCH America Corporation is at the forefront of manufacturing technology, renowned for delivering innovative solutions that meet the evolving needs of the industrial sector. The introduction of centroteX underlines the company’s commitment to providing advanced technology that ensures efficiency and precision across a variety of manufacturing applications.

View more news from HAINBUCH America Corporation