HAIMER, a leading provider in the manufacturing sector, is setting new benchmarks by promoting tool assembly standardization. This approach aims to minimize setup inconsistencies and boost production efficiency in machining environments.

Standardizing tool assembly can significantly reduce unexpected issues during the setup process. By ensuring that tool assemblies are consistently prepared, manufacturers can achieve more predictable results and enhance repeatability. This method provides a foundation for confidence and control within daily production operations.

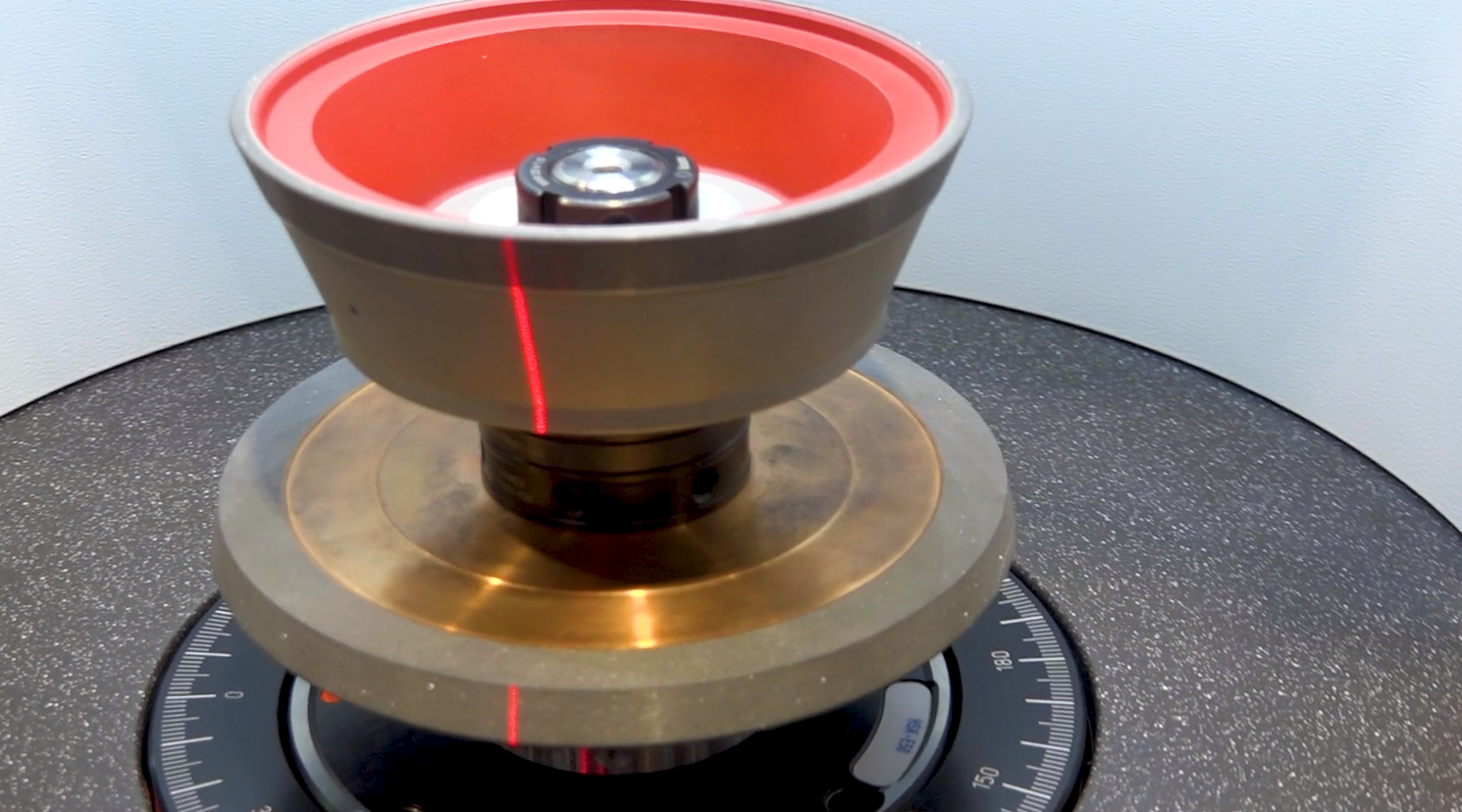

HAIMER’s commitment to supporting setup standardization showcases their dedication to improving tool room efficiency. Their tools ensure that manufacturers have the resources needed to stabilize and streamline their production processes. This commitment is further demonstrated through HAIMER’s array of products designed to meet the precision and quality demands of the industry.

Manufacturers looking to optimize their tool room operations can explore HAIMER’s solutions that facilitate these standardization processes. By doing so, they can enhance their production capabilities, reduce machine downtime, and improve overall product quality.

Headquartered in Igenhausen, Germany, HAIMER continues to lead the way in precision machining and quality toolholding. Their global presence and innovative solutions make them a key player in advancing manufacturing technology.

View more news from HAIMER USA