GF Machining Solutions Launches Revolutionary CUT X EDM Series with AI and Additive Innovations

Switzerland-based GF Machining Solutions has unveiled its latest advancement in electrical discharge machining (EDM) — the CUT X Series. Designed at its Losone facility, the new CUT X 350 and CUT X 500 models are redefining performance expectations for wire EDM, offering unmatched precision, thermal stability, and production flexibility.

The CUT X 350 supports workpieces up to 800 x 550 x 250 mm, while the larger CUT X 500 handles dimensions up to 1,050 x 700 x 250 mm. These machines are built around a completely new thermal management architecture. An advanced sealed design maintains consistent internal conditions, isolating heat sources and using optimized airflow to ensure machining accuracy regardless of external temperature fluctuations.

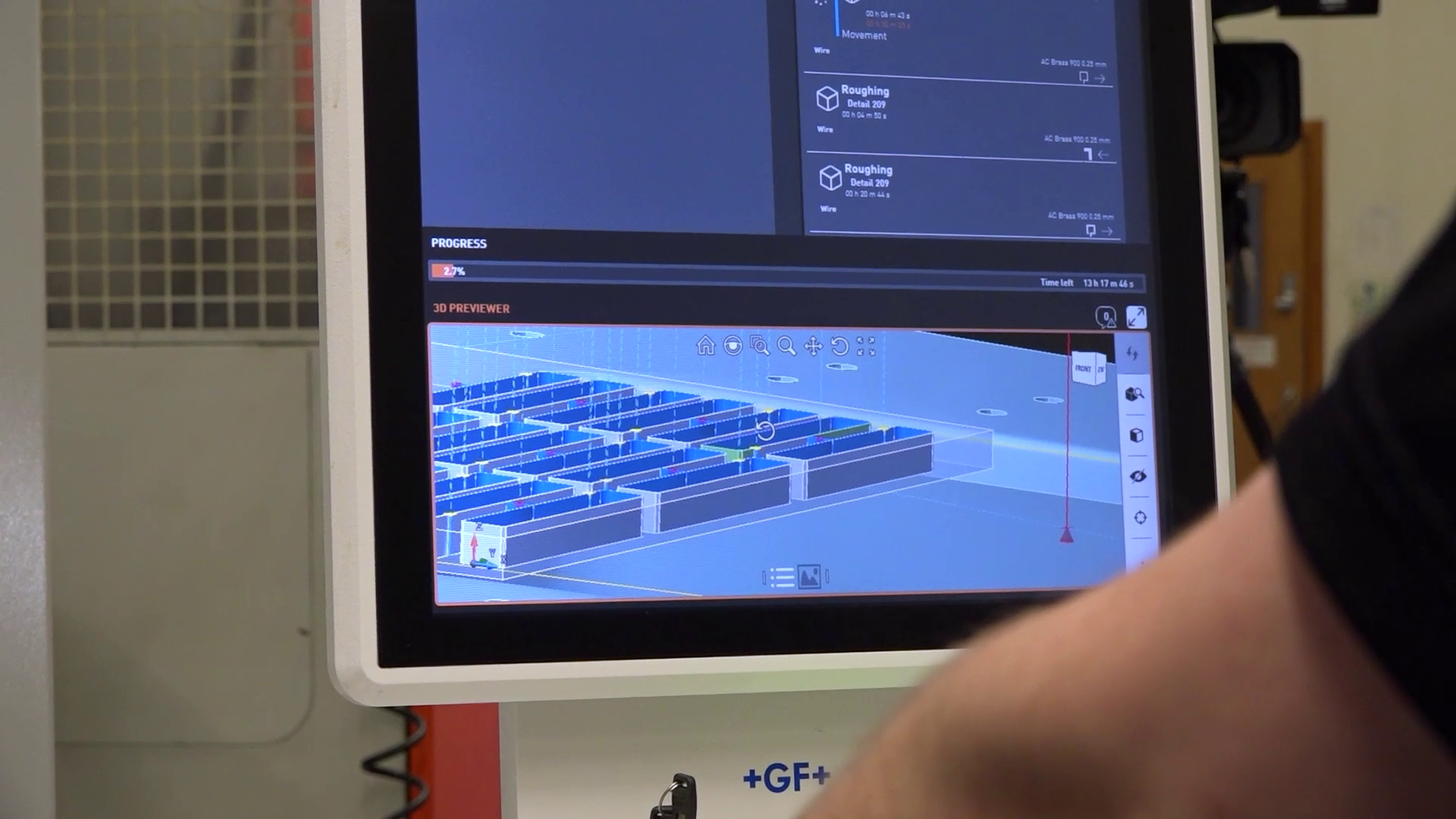

At the core of the CUT X series is an AI-driven CNC system that continuously collects data from multiple temperature and humidity sensors placed both inside and outside the machining chamber. This system anticipates thermal deviations and compensates across the X, Y, U, and V axes, delivering highly accurate cuts even during extended operations.

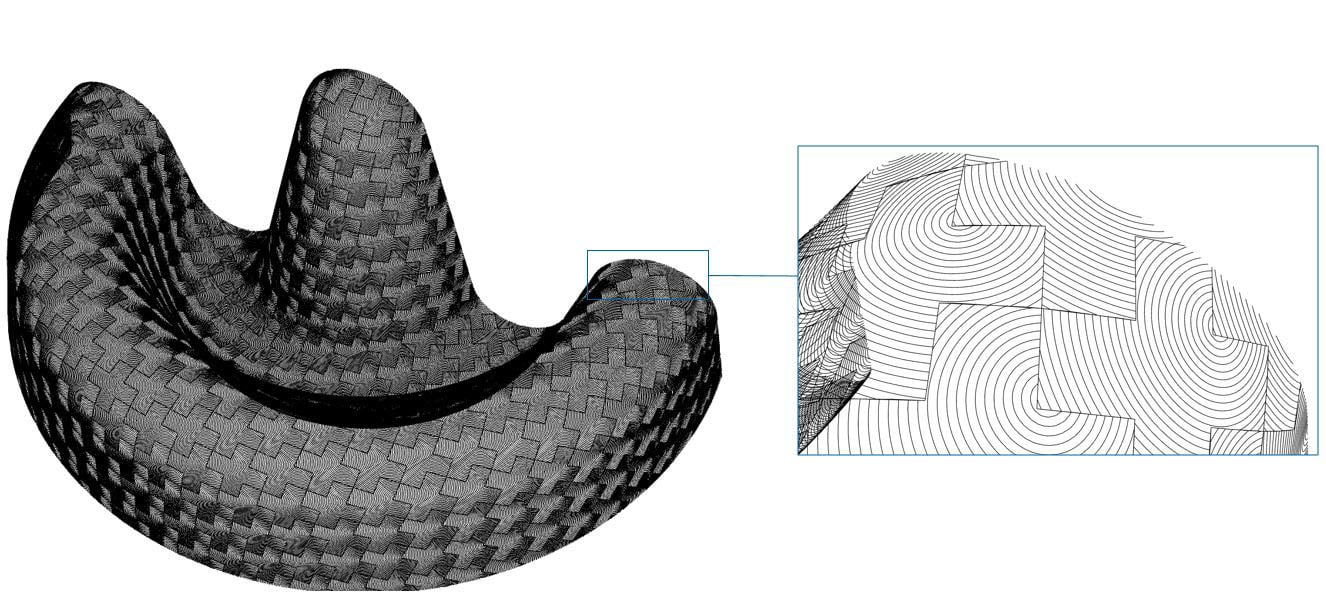

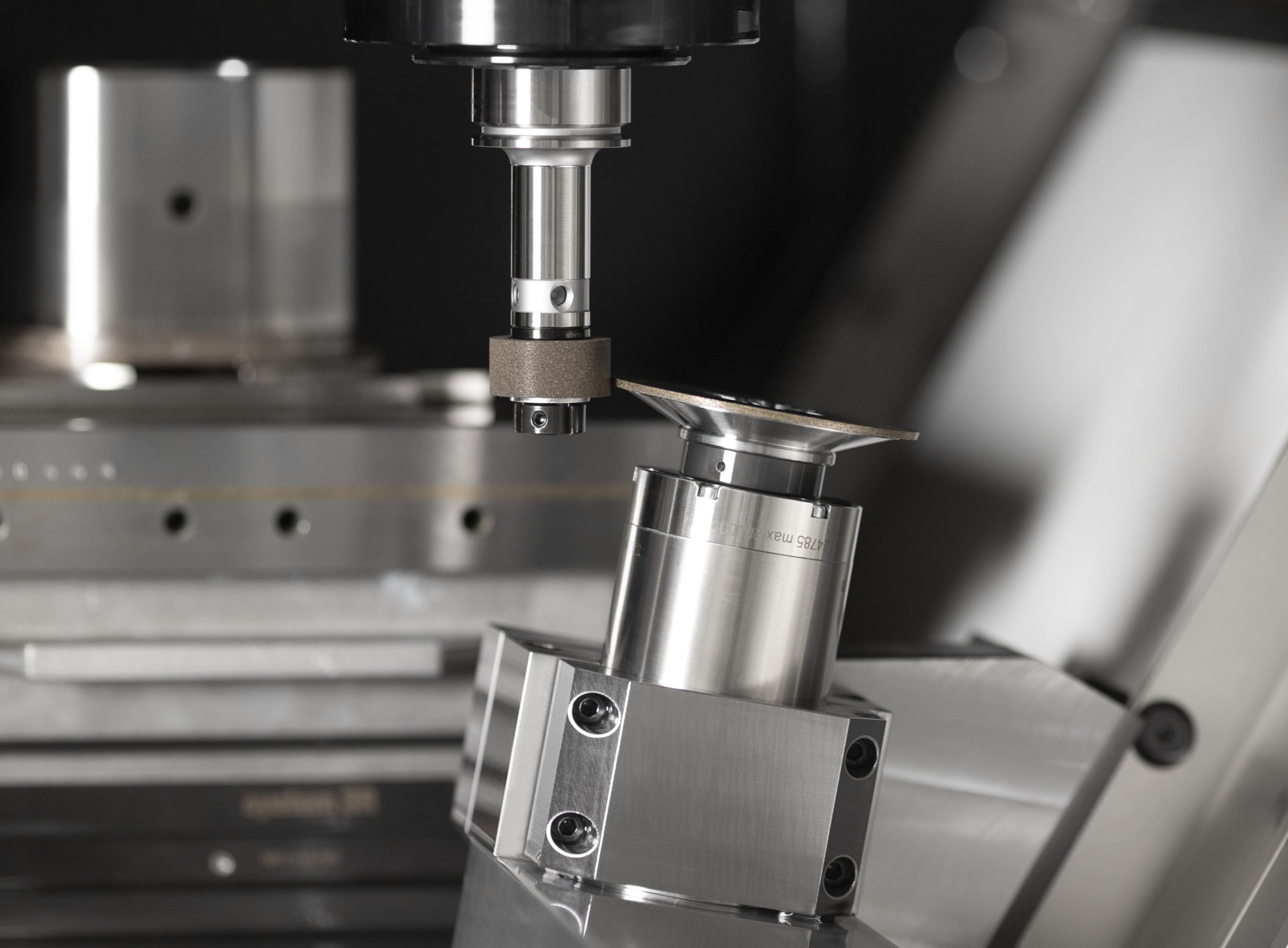

One of the series’ standout features is its interchangeable wire guide system, allowing operators to easily switch between open (V) and closed (round) guides in under 15 minutes. Open guides excel in straight or shallow taper cuts, while closed guides offer superior performance for complex geometries and tapers up to 30°. These guides support various wire diameters without frequent adjustments, enhancing both versatility and uptime.

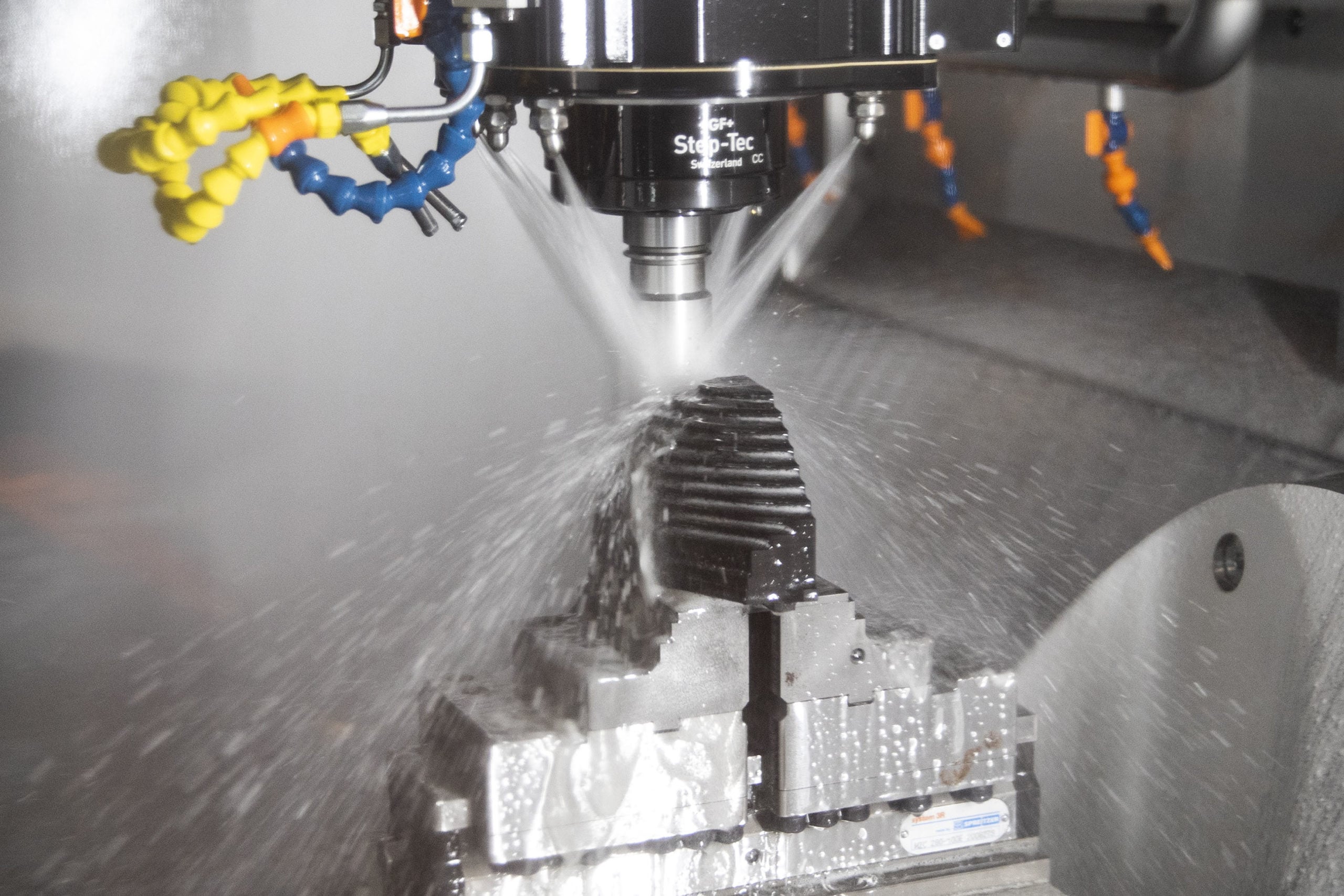

The CUT X Series also incorporates newly additively manufactured upper and lower heads, which bring the guides closer to the part for enhanced precision and increased flushing efficiency — boosting both accuracy and speed. Operators benefit from the intuitive UNIQUA human-machine interface, featuring a 19-inch touchscreen, full keyboard and mouse, and legacy compatibility with older EDM file formats.

GF’s Intelligent Power Generator with Direct Power Supply (IPG-DPS) automatically calibrates power settings to meet surface finish and accuracy requirements. Additional automation features, such as the Automatic Wire Changer (AWC), dual-wire circuits, and real-time spark monitoring through Spark Track and ISPS, ensure continuous, high-quality production.

For lights-out operations, the machines include an integrated Z-axis touch probe for auto-alignment, an automatic slug removal system, wire threading, a built-in wire chopper, and double-wire spools — pushing the boundaries of EDM automation.

With the CUT X Series, GF Machining Solutions combines cutting-edge AI, additive manufacturing, and smart automation to challenge industry norms and set a new standard for EDM performance.