FANUC’s Latest ROBODRILL Delivers BT40 Performance with BT30 Efficiency

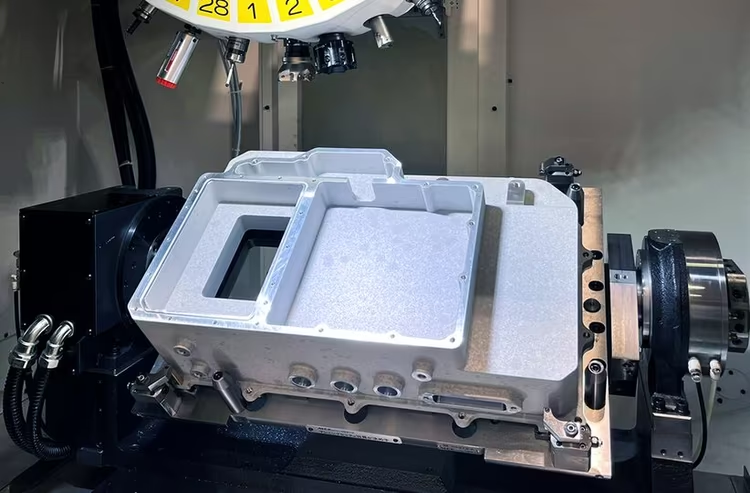

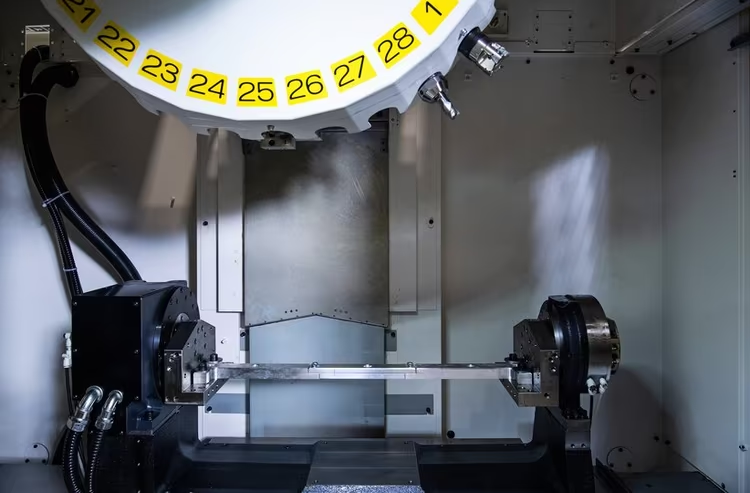

FANUC has unveiled the next step in high-speed vertical machining with the new ROBODRILL α-D28LiB5ADV Plus Y500, bringing even more capability to its already proven ROBODRILL Plus series.

Engineered for peak performance in modern production environments, this new machine offers:

- A larger table and 500mm Y-axis stroke for handling bigger components

- Faster drilling and tapping cycles through 2.2G Z-axis acceleration

- 28-tool capacity and rapid tool changes

- All without increasing the machine’s footprint

But what really sets the Y500 apart is how it bridges the gap between BT30 and BT40 machining, giving users the speed and precision of a compact machine with the productivity and capability traditionally reserved for heavier platforms.

This powerful combination is helping FANUC reach a broader range of customers globally, including growing SMEs and automation-driven businesses that demand both high performance and cost efficiency.

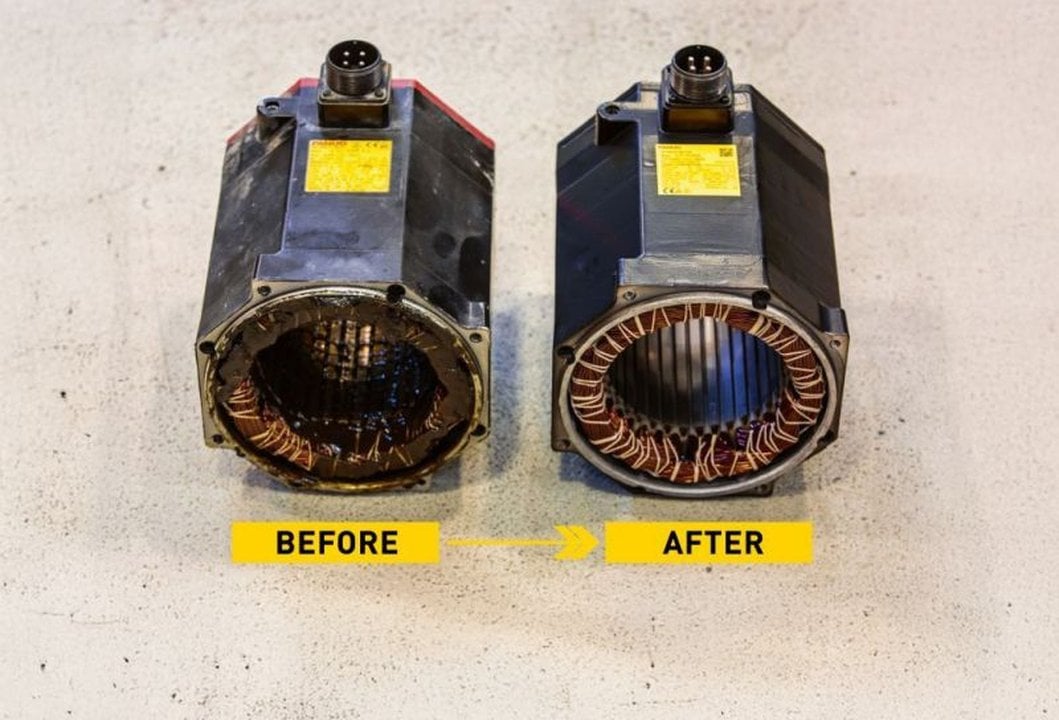

FANUC UK’s Coventry HQ is home to a number of ROBODRILL machines, all set up and running for live demonstrations. Manufacturers are encouraged to visit, speak with FANUC’s experts, and even bring their own parts to see how ROBODRILL performs under real-world conditions.

From lights-out automation to everyday high-speed milling, ROBODRILL continues to be the go-to choice for uptime, economy, and flexibility — now with even more muscle.

📍 Interested in what ROBODRILL can do for your business? Book a visit to FANUC UK and see the machines in action.