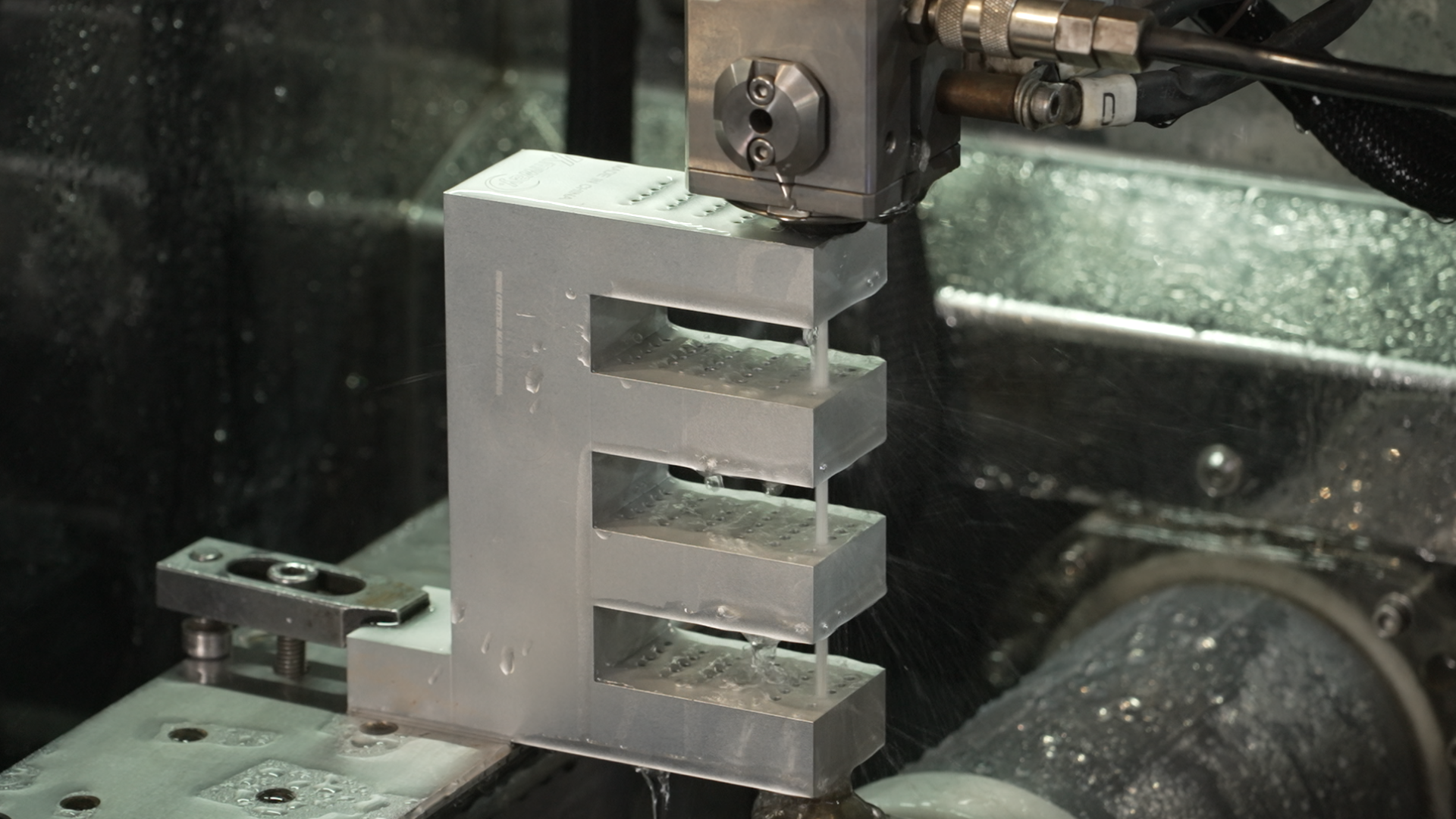

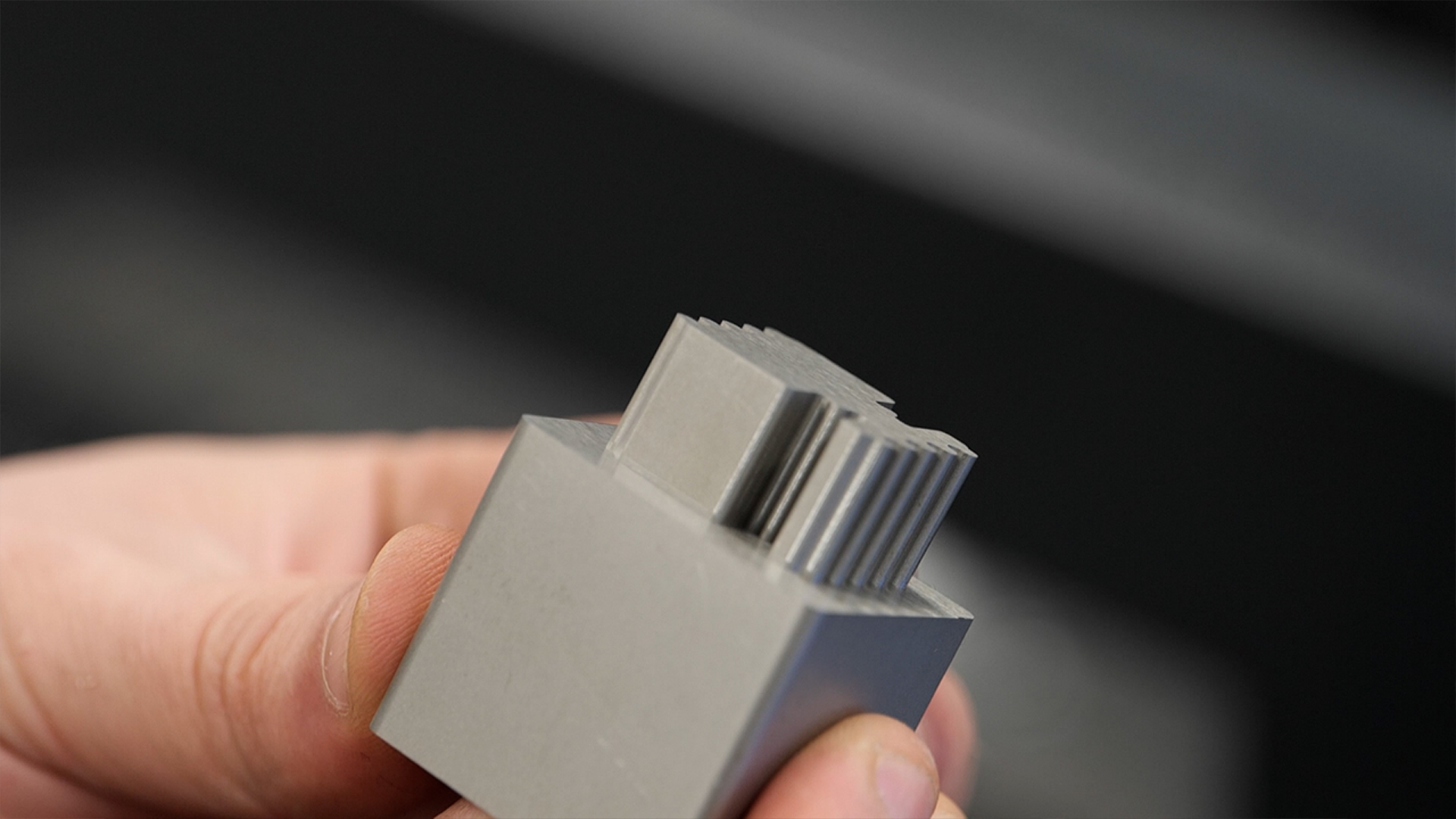

A newly installed Kmway EK Series Wire Electrical Discharge Machine (EDM) is already making waves in the manufacturing sector. Following installation and on-site training, a UK manufacturer is nearing completion of its first batch of parts with the machine, highlighting its immediate impact on productivity.

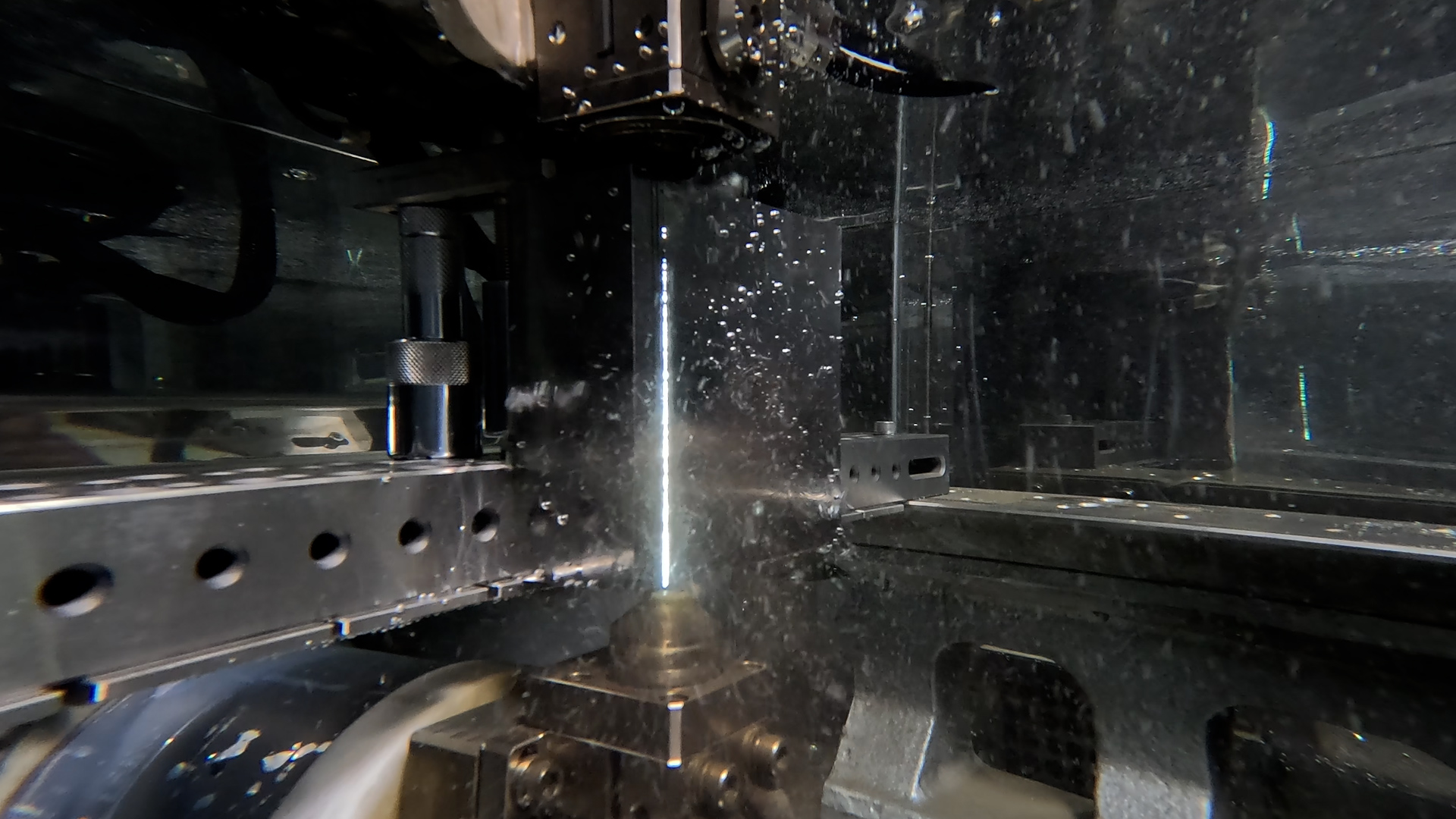

The Kmway EK Series is designed for manufacturers prioritizing accuracy, efficiency, and long-term reliability. Its compact footprint and advanced systems make it ideal for tight workshop spaces without compromising capability. The machine features Next-Generation Auto Wire Threading (AWT), which ensures ultra-reliable threading, maximizing uptime and minimizing the need for operator intervention.

One of the standout features of the EK Series is the optional Linear Motor Drive that offers frictionless, backlash-free motion, enhancing cutting accuracy and reducing wear compared to traditional lead screws. Its thermally balanced, ultra-rigid solid frame ensures stability and consistent dimensional accuracy, even during extended or high-load machining operations.

The machine also boasts an advanced filtration system that lasts three to five times longer than typical filters and can be changed quickly, thereby minimizing downtime. Its operator-friendly head design allows for easy maintenance, further ensuring high-quality outputs.

With decades of experience in EDM technology, Kmway continues to offer cutting-edge, energy-efficient solutions trusted by manufacturers worldwide. In Europe, the EK Series is available exclusively through Eurospark, a company with over 30 years of specialization in EDM technologies.

Manufacturers seeking a cost-effective, high-quality EDM solution can look forward to new stock available early in the new year.

Read this post on LinkedIn