Nakamura-Tome Launch New ‘Triangle-Cut’ Function

Nakamura-Tome has announced a newly developed chip-breaking function ‘Triangle Cut’ for its high-end precision turn/mill centres that is available in the UK from the Engineering Technology Group (ETG). The Triangle Cut technology can be applied to all slide-guided machines, including box-way machines that cannot utilise Nakamura-Tome’s existing ‘Oscillating Cutting’ function. With this exciting new arrival, it is now possible to install a chip-breaking function on all machines in the Nakamura model lineup.

What is the Triangle Cut?

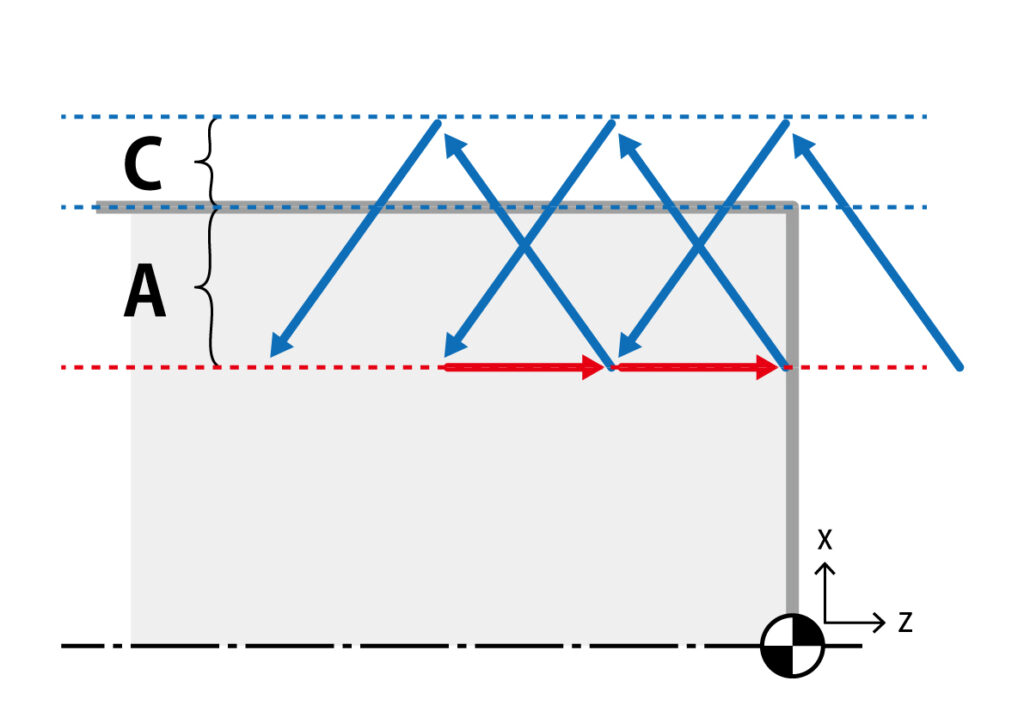

Triangle Cut is an optional function that breaks chips by operating the turning tool paths in a triangular trajectory. Moving the tool path in a triangular route moves the cutting edge away from the workpiece to split the chips as the tool oscillates between the workpiece and air cutting.

Advantages

Compared to the ‘Oscillation Cutting’ that is already available on some Nakamura models, the Triangle Cut tends to reduce surface roughness by 1.2 to 2 times the level of normal turning operation. However, there is a compromise between improved surface finishes and effective swarf management. The machining time could be extended by 2.7 to 3 times due to the extension of the processing path. In many instances, machine shops will be reluctant to run machines unmanned overnight due to swarf management issues that can arise when machining particular materials. It is in these situations that ‘Triangle Cutting’ can benefit the end user – it is better to run lights-out with process stability and chip management at a slower speed than to not machine at all.

Development background

The cutting chip problem is unavoidable for production sites, and the burden on customers can be heavy. With the evolution of Nakamura-Tome machinery and servo technology, the Oscillating Cutting function has been put to practical use, and its programming can easily solve chip problems. However, the Oscillation Cutting is difficult to apply to slide-guided machines because they are at risk of damage due to the high-speed movement of the Oscillation Cutting cycles.

Nakamura has received numerous inquiries regarding the application of Oscillation Cutting to box-way machines. To address this issue, the company has developed Triangle Cut. Instead of using a special program, Nakamura has devised a way to perform chip-breaking operations by adding simple modifications to the processing program already in use. For further information on this incredible innovation, please contact ETG for details.