High-Precision GER CP-CNC Grinder Debuts for Heavy-Duty Applications

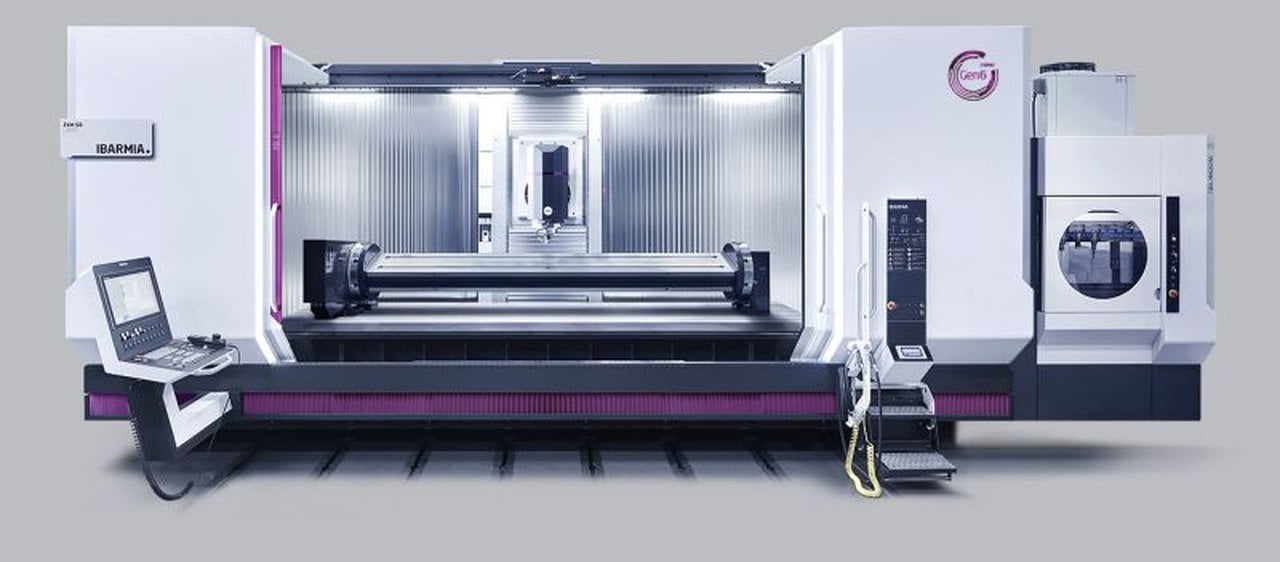

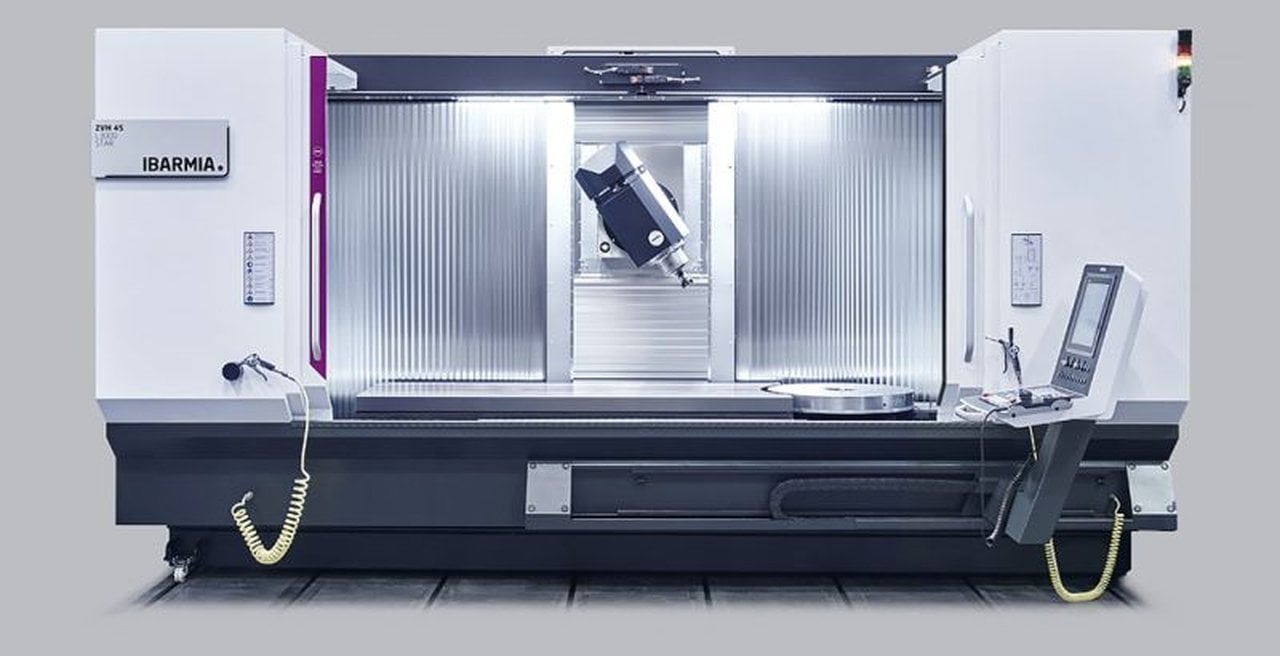

The GER CP-CNC series has been introduced as a high-capacity CNC cylindrical grinding machine engineered to meet the precision needs of heavy-duty industrial environments. Known for its robust construction and advanced technology, this machine is adept at external cylindrical grinding of large components.

Built with a stabilised ribbed cast-iron structure, the GER CP-CNC provides exceptional rigidity and reliability. It supports impressive workpiece dimensions, capable of handling pieces up to approximately 4,000 mm in length, 800 mm in diameter, and 4,000 kg in weight. This makes it an ideal solution for industries requiring precision with large workpieces.

Key features include the latest FANUC 0i-TF CNC control, which offers a graphical, user-friendly interface and ISO programming. The intuitive software enhances usability with touchscreen programming, graphical cycle screens, profile following, and on-screen visualisation of complex profiles. Users benefit from USB and Ethernet connections for programme input and saving, allowing for in-cycle modifications without altering original programs.

Optional equipment extends the machine’s capabilities, including an internal grinding spindle, C-axis for non-cylindrical profile grinding, and automated loading/unloading systems. In-process gauging and measurement systems further enhance its precision capabilities.

Manufactured in Spain by GER Máquinas Herramienta S.L.U., the CP-CNC is fully supported in the UK by DTS (UK) Ltd. This machine combines precision, repeatability, and heavy-duty performance, making it a significant addition to modern cylindrical grinding applications.

For those interested in enhancing their grinding capabilities, DTS (UK) Ltd offers consultation to specify the ideal CP-CNC configuration for various production needs.

View more news from DTS (UK) Ltd