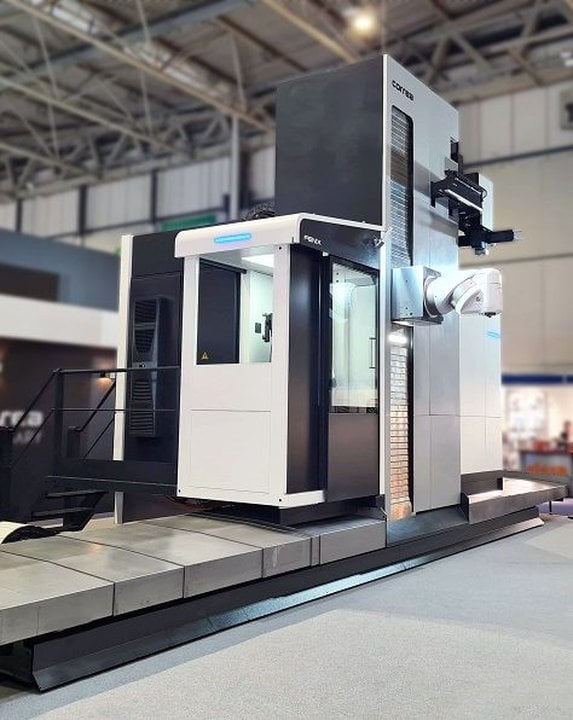

Nicolás Correa S.A. has launched the Correa NORMA L, a state-of-the-art milling machine, designed to address the needs of manufacturers requiring large-scale, high-performance machining. Engineered for strength and precision, the NORMA L is perfectly suited for medium-to-large components demanding consistent accuracy and reliability in demanding industrial applications.

One of the standout features of the Correa NORMA L is its automatic universal head, available in Correa’s UDG or UAD models. This feature allows for multi-face machining in a single setup, dramatically reducing cycle times and providing increased flexibility. Users can select between Heidenhain or Siemens controls, catering to various operator preferences and shop floor systems.

The machine’s high dynamic performance is supported by rapid traverse speeds, enabling efficient machining cycles. Additionally, its powerful spindle options are designed to handle heavy-duty cutting and challenging materials effortlessly.

The NORMA L is constructed with oversized structural elements, ensuring maximum rigidity, stability, and long-term accuracy. Its eco-friendly design includes energy-saving standby features and automatic switch-off functions, contributing to reduced energy consumption.

Optional features enhance the machine’s versatility. These include automatic tool changers with up to 60 tools, rotary tables, measurement probes, chip conveyors, and advanced coolant systems.

Key products from Nicolás Correa are exclusively supported in the United Kingdom by DTS (UK) Ltd. The company’s commitment to providing cutting-edge solutions for the manufacturing industry is evident in the Correa NORMA L, offering precision, power, and durability for the most demanding applications.

For those interested in adding the Correa NORMA L to their production line, DTS (UK) Ltd offers expert guidance in selecting the optimal configuration.

View more news from DTS (UK) Ltd