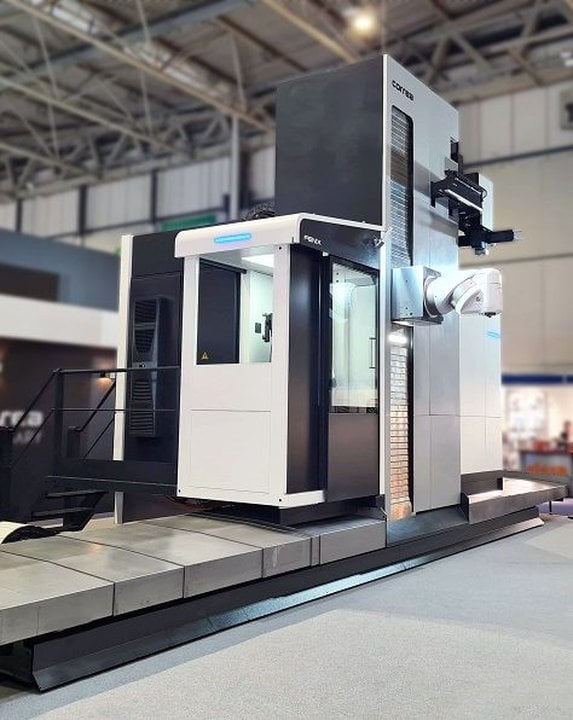

The Correa Fenix, a gantry-type milling machine developed by Nicolás Correa, offers precise and reliable machining solutions for industries tackling large and heavy components. Known for its engineering finesse, the Fenix is designed to deliver power, precision, and structural stability, crucial for demanding manufacturing tasks.

The Fenix’s robust gantry-type architecture enhances rigidity and geometric stability, even when machining sizable or weighty components. It is compatible with advanced CNC control systems, allowing operators flexibility in integrating with their existing shop floor setups. With high-torque milling capabilities, the Fenix supports challenging cutting strategies, making it ideal for a variety of materials.

Featuring smooth axis motion and a dynamic performance design, the Correa Fenix promises efficient machining cycles. Its solid mechanical construction ensures long-term accuracy and reliability, maintaining repeatable performance over extended use. This advanced system also includes smart connectivity features, enabling remote monitoring and diagnostics to boost uptime and productivity.

Optional equipment for the Fenix includes automatic tool changer configurations, probing systems, advanced measurement tools, and customizable chip management and coolant solutions. Additional guarding and automation configurations can be tailored to specific application needs.

Nicolás Correa S.A.’s Fenix reflects the company’s dedication to precision engineering, supported in the UK by DTS (UK) Ltd. Their expertise assists manufacturers in selecting the right configuration to optimize their production lines.

View more news from DTS (UK) Ltd