Ten sliding-head lathes in five years transform production efficiency

Established in 1995, toolmaking, metal pressings and plastic injection moulding services provider TWP Manufacturing Group, Tipton, started making a range of proprietary products after the financial crisis of 2008 to build business resilience. They include photographic studio and darkroom equipment, gardening items such as wheelbarrows, and spiral security anchors. Most of the items that go into them, including stamped metal platework, milled components and moulded plastic parts, are produced in-house and assembled into the various products, together with a large variety of turned parts that historically were mainly sourced from suppliers in the Far East.

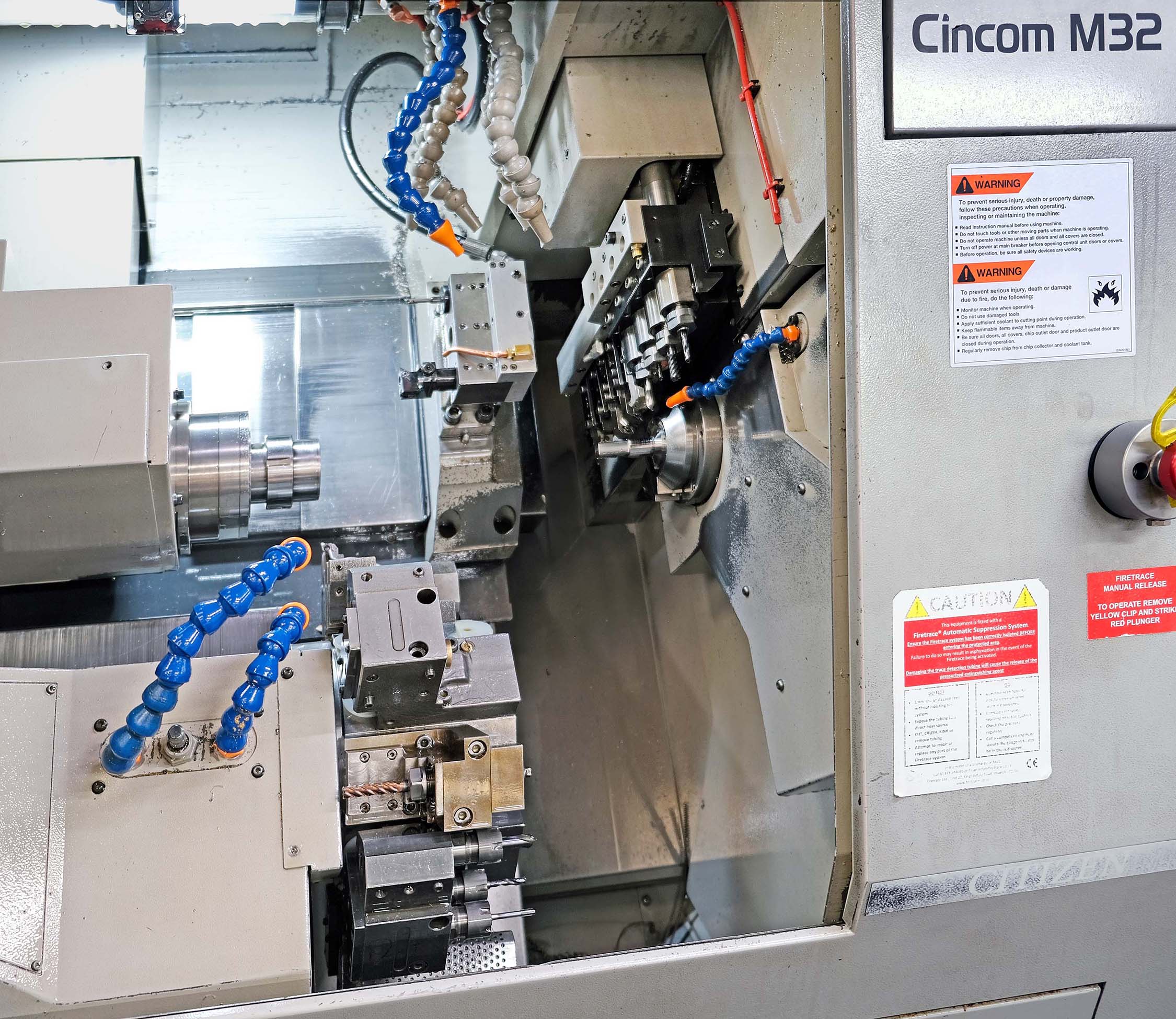

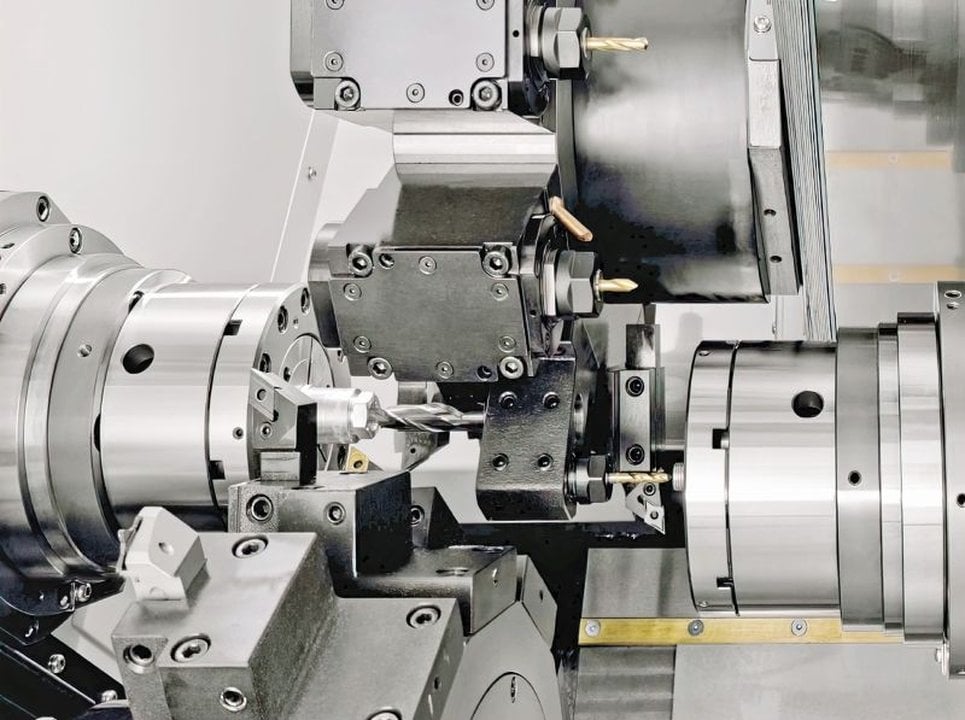

That changed in May 2020 with the purchase at auction of a Japanese-built, CNC sliding-head turning centre, a Citizen Cincom M32 that was 19 years old at the time. The twin-spindle, 32 mm capacity, bar-fed lathe, equipped with a tool turret, a gang-type tool post and a back tool post for reverse-end machining, brought in-house about half of the outsourced turned parts production.

Fast-forward five years to the spring of 2025 and the number of such machines on the shop floor had risen to 10, all pre-owned and mostly of similar age. Not only had all the previously subcontracted turn-milling work long since been repatriated, but a turned parts subcontracting business had also been established that now accounts for 30% of the firm’s £4.2 million current annual turnover.

Five years ago, income was £2.5 million per year, which means that business has increased by more than two-thirds in that time. Notably, during the same period the headcount has decreased by 20%, to 28 staff, so earnings per person employed has jumped by more than double.

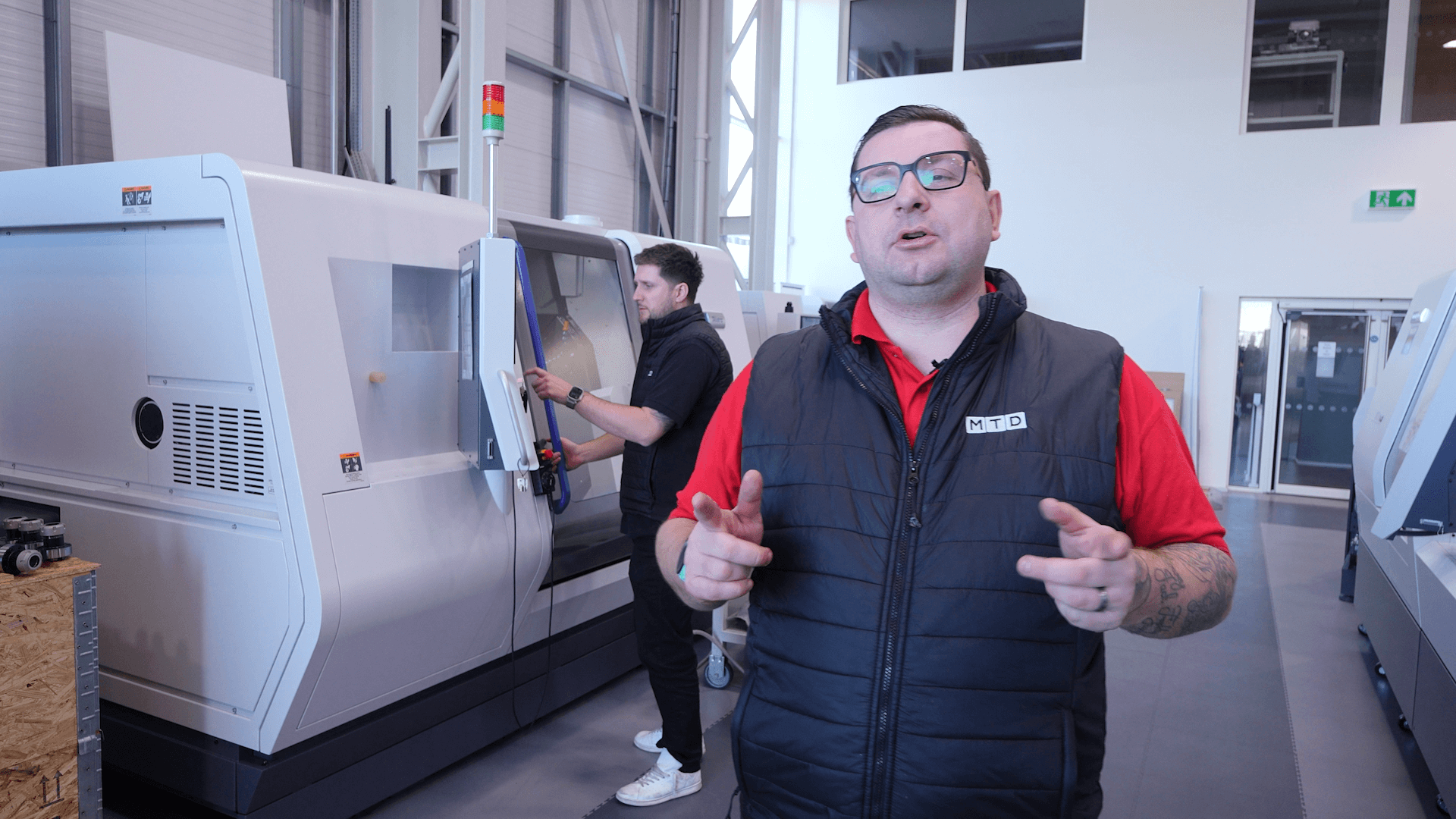

Phil Stanley, joint owner of TWP together with partner Richard Perry, said, “Our relationship with Citizen Machinery UK has been brilliant since the start. Despite our repeated purchase of used machines, nothing has been too much trouble for them over the years.

“They were there for us when we installed the first M32, helping with advice and early programs. If the assistance from their engineers had not been forthcoming, we would not have been able to progress.

“The support we have received all the way through each of the 10 lathe installations, including refurbishment and realignment of the machines, has been second to none and they are still behind us every step of the way.”

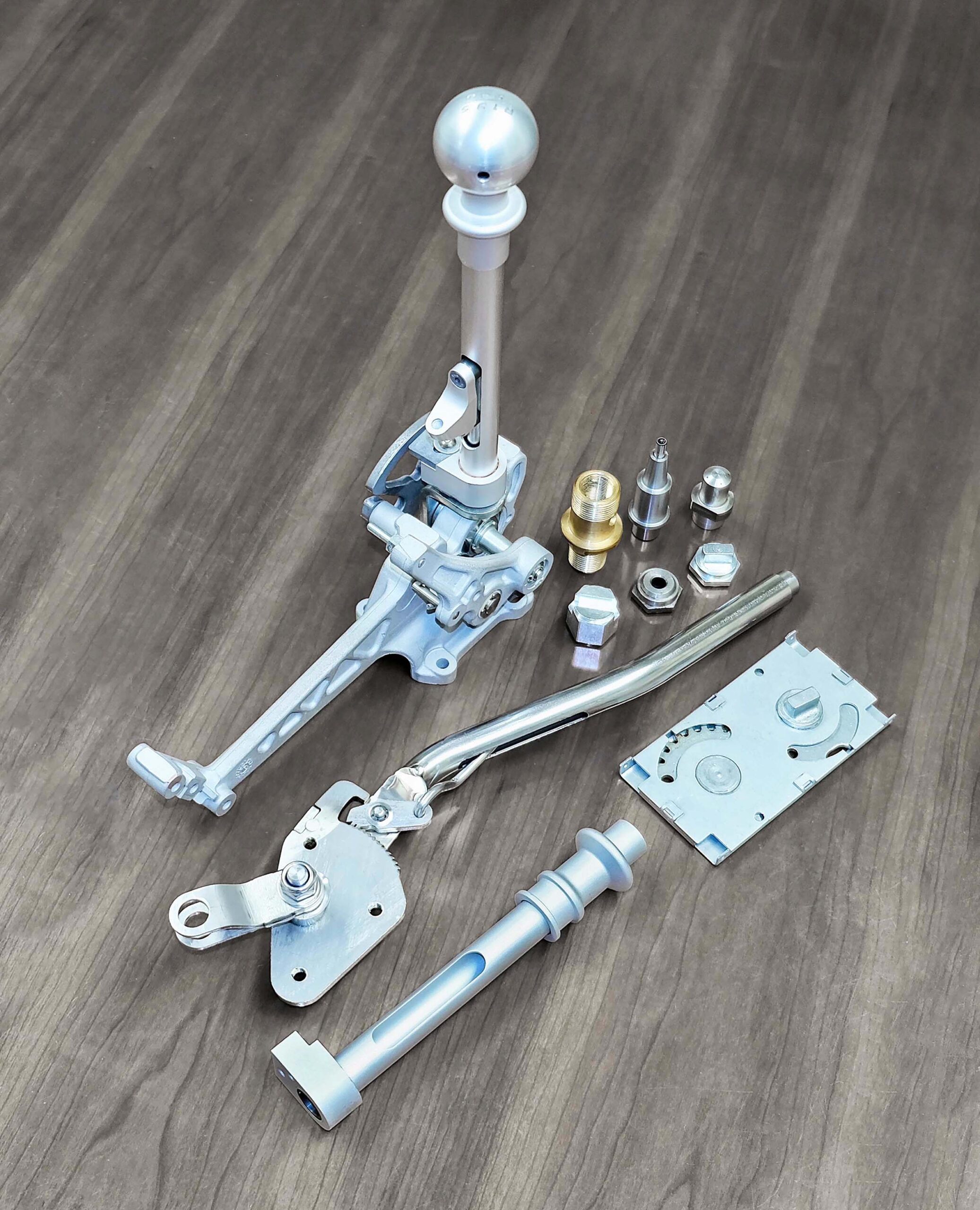

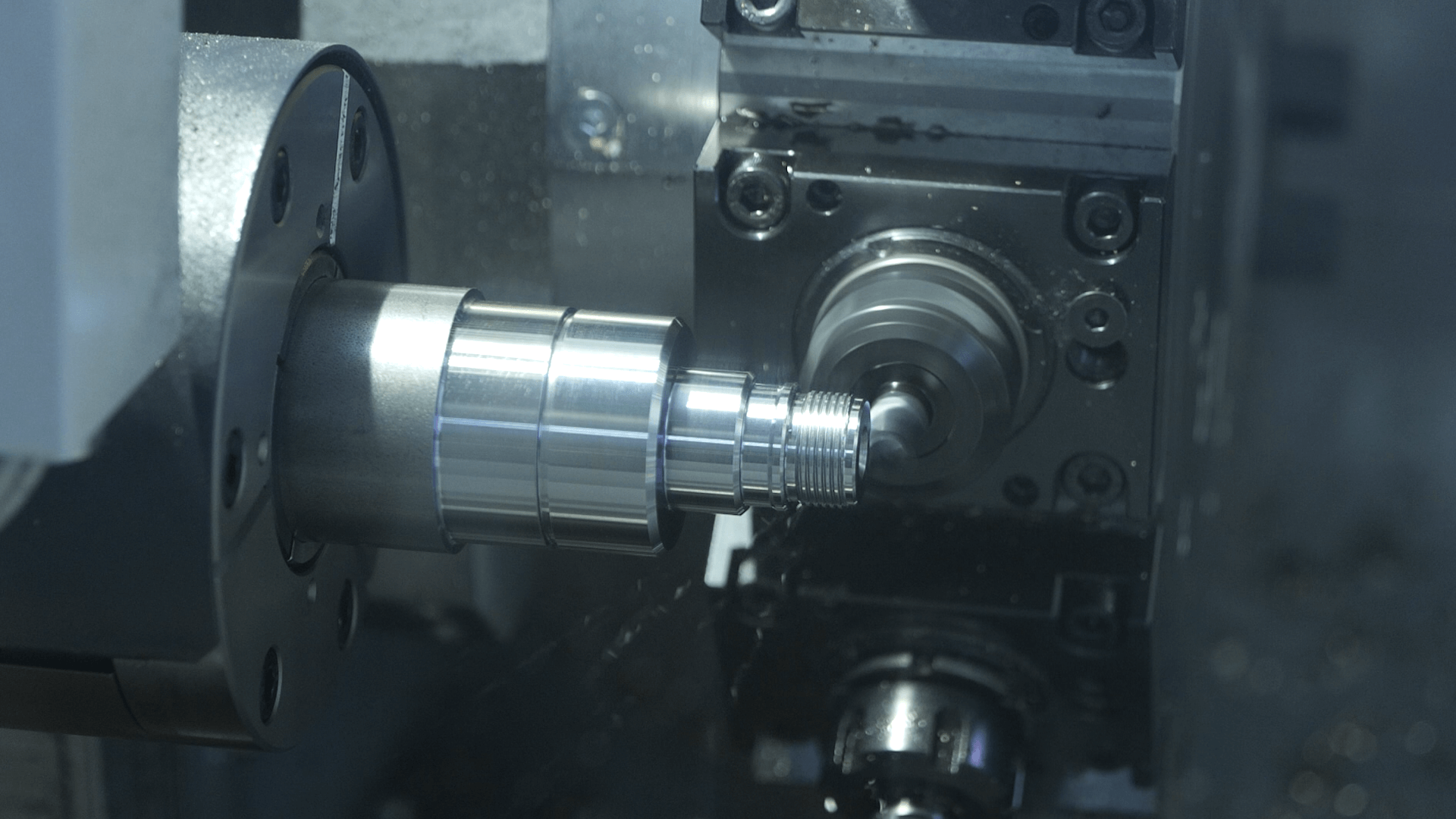

Four months after the first Cincom arrived, a second Citizen sliding-head lathe of the same bar capacity was acquired, an L32 equipped with exclusively gang tooling and the facility to eject shaft-type components through the sub spindle. It proved ideal for producing a main component in one hit for the gear shift lever of a Lotus car. Virtually every other component that comprises the assembly is also produced in-house.

To provide extra capacity, bring down lead-times and allow TWP to introduce just-in-time manufacturing procedures, a second M32 was purchased in May 2021. By this stage, all turn-milled parts production had been insourced. It also allowed the manufacturer to get ahead with forward orders and gain new business.

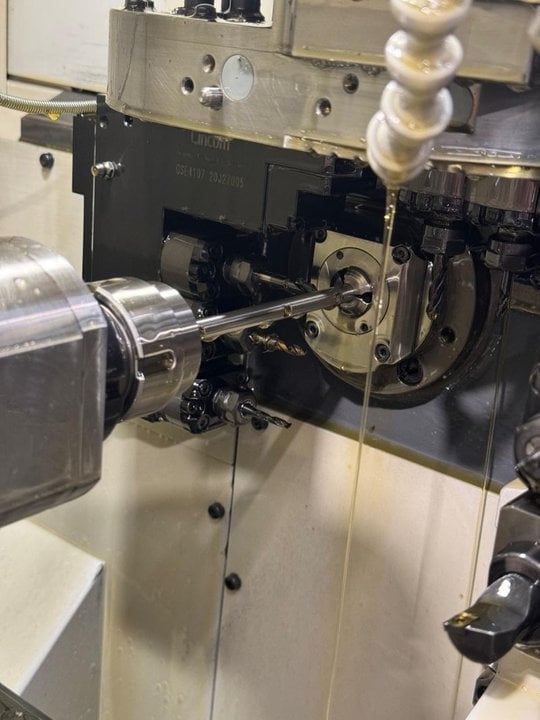

With the aim of transferring sub-12 mm diameter parts production from the 32 mm capacity sliding-head turning machines to more appropriately sized, nimble lathes, two B12 Cincoms arrived in August 2022. Among numerous other jobs, they are used around the clock every week for turning 10,000 mild steel pins that go into control boxes for heating and ventilating systems.

The following year, in June and August respectively, Citizen delivered two 20 mm capacity Cincom L20s, enabling work to be allocated more efficiently across the shop floor. It also avoided having to set up machines before a batch run had finished to accommodate a contract that needed to be fulfilled urgently. The extra lathes provided much-needed additional capacity to cope with more work that was being received from existing and new customers.

Wishing to produce components from larger bar up to 64 mm diameter, Mr Stanley opted for a triple-turret lathe from Citizen’s other product line, Miyano. An early job put onto the machine compressed into a single operation the manufacture of a high-strength 6082 aluminium T6 cable link for the Lotus gear shift. Before the machine’s installation, the maximum bar diameter that could be processed in the Tipton factory was 55 mm.

Most recently, following the clearance of a storage room to provide additional manufacturing floor area and the relocation of various machines, two additional Cincom models were added in February and April 2025, both M32s. This part of TWP’s facility was officially opened on 14th March 2023 by West Midlands Mayor Andy Street and Shaun Bailey, MP for West Bromwich West at the time, who both also toured the entire factory comprising three industrial units.

Despite the Citizen lathes all being second-hand, which allowed TWP to buy them without the need for finance, the Citizen lathes work like new machines, according to Mr Stanley. He said, “We hold a general tolerance here of ± 0.05 mm, but we have turned a carbon steel pin to +0 / -2 µm on the L32 – not bad for a lathe built a quarter of a century ago!”

He puts this performance down to the extreme rigidity of Citizen lathes, coupled with the use of good quality coolant and judicious choice of feeds and speeds. This combination not only promotes high dimensional accuracy and good surface finish, but also long tool life. He noted recently that on one lathe, each edge of a carbide insert, when machining parts from mild steel bar, did not need to be indexed or replaced before 1,800 parts were produced.

A total of 800,000 turn-milled components per year are machined on the 10 Citizen lathes, two-thirds of them from mild steel, while stainless steel accounts for another 30% of throughput. As a large proportion of components include spanner flats, extensive use is made of hexagonal bar to avoid milling them and lengthening the cycle times. The robustness of the Citizen lathes, and their ability to withstand the inevitable vibration when turning such bar, is a major benefit in this respect as well.