C & M Precision Limited, a renowned manufacturer in the precision turned parts sector, has successfully utilized advanced machinery to address a significant mail merging system project. The application of Citizen CNC’s Cincom L12-X and L32-XII machines has optimised their production capabilities, ensuring high accuracy and efficiency.

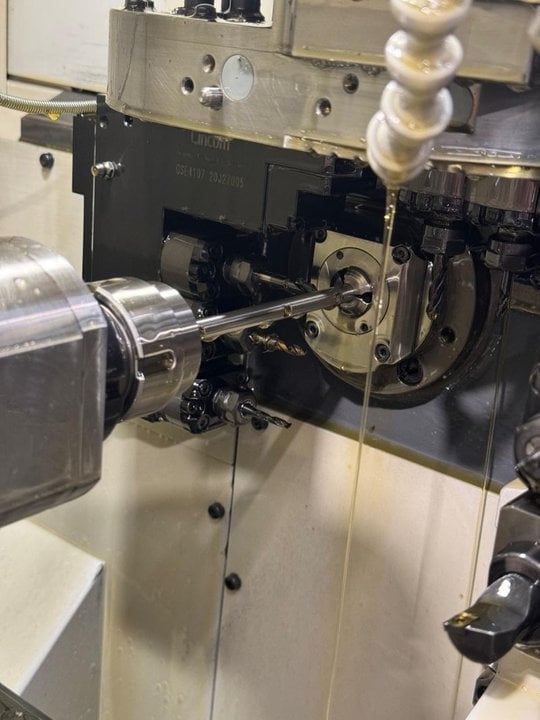

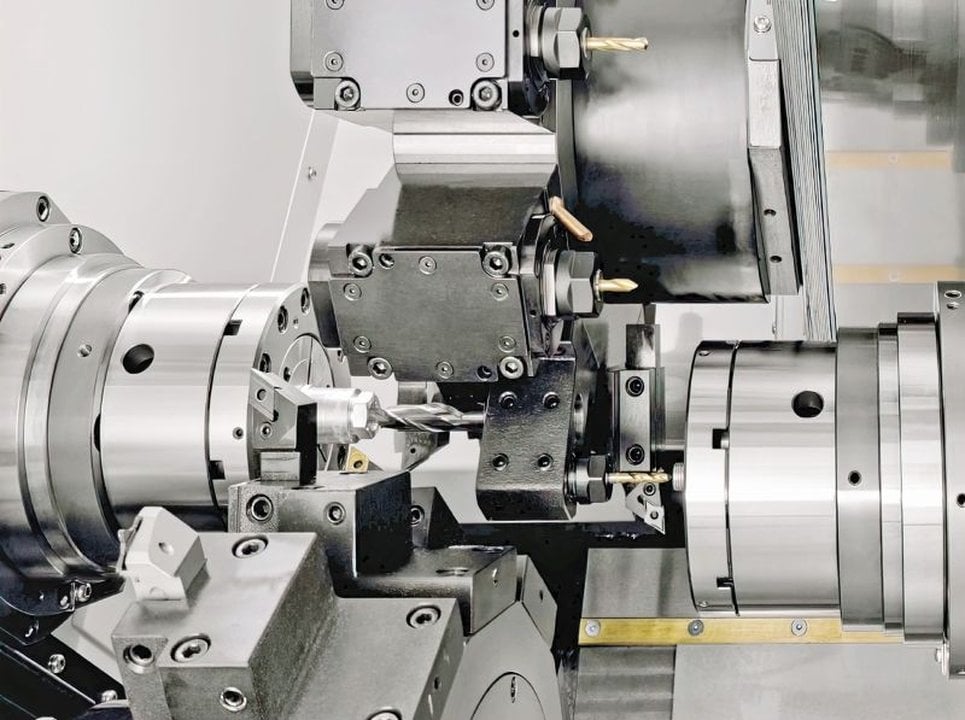

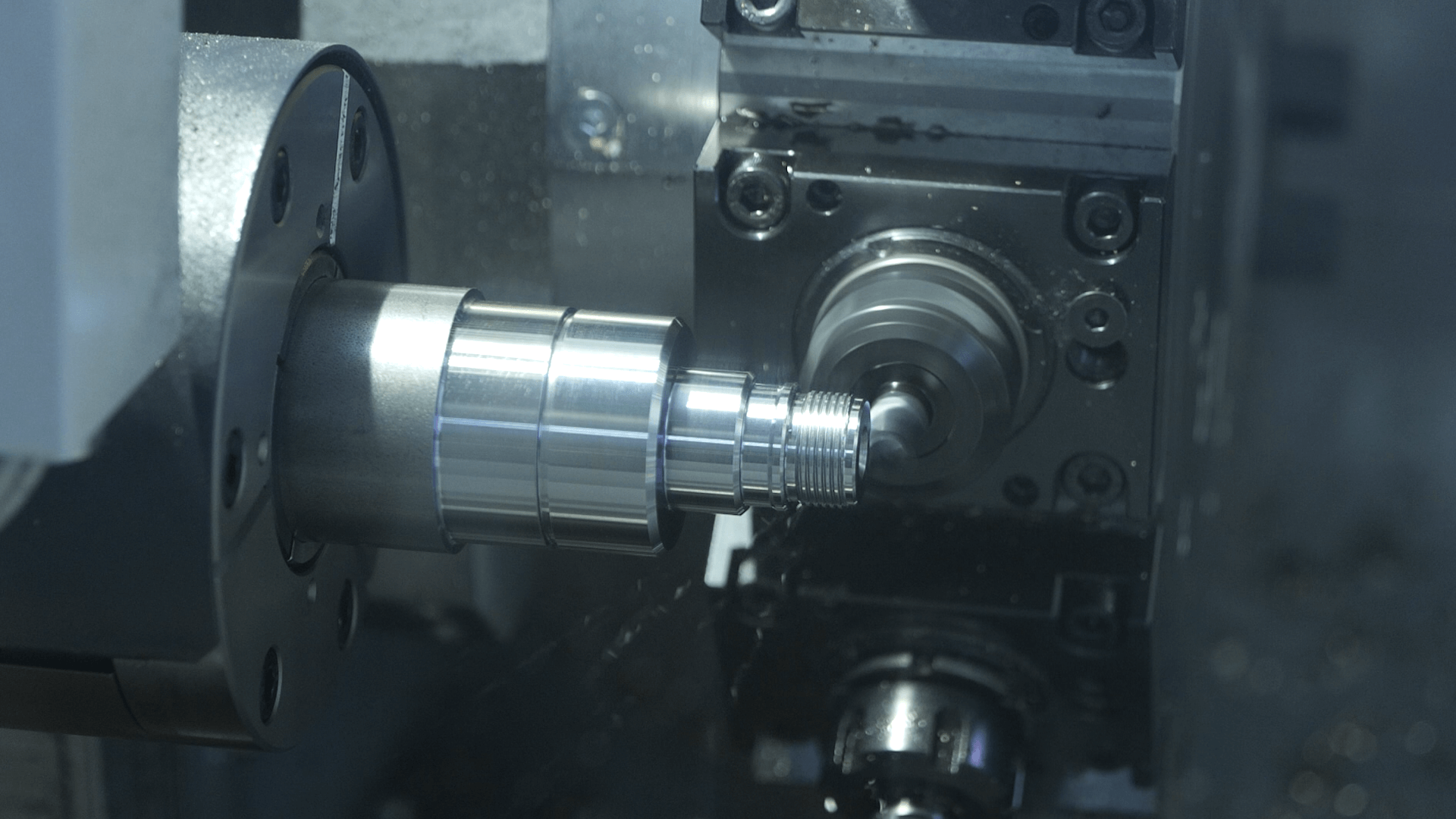

The project involved the sophisticated use of multi-chucking processes. This method allows components to be produced in various stages, transferring seamlessly between the main and sub spindles. The process ensures rigidity, perfect alignment, and dimensional precision across the complete length of the component.

In addressing challenges such as vibration and deflection during transfer, C & M Precision Limited implemented robust support mechanisms. This approach protects the integrity of the components, ensuring they meet the stringent demands of modern mail merging systems.

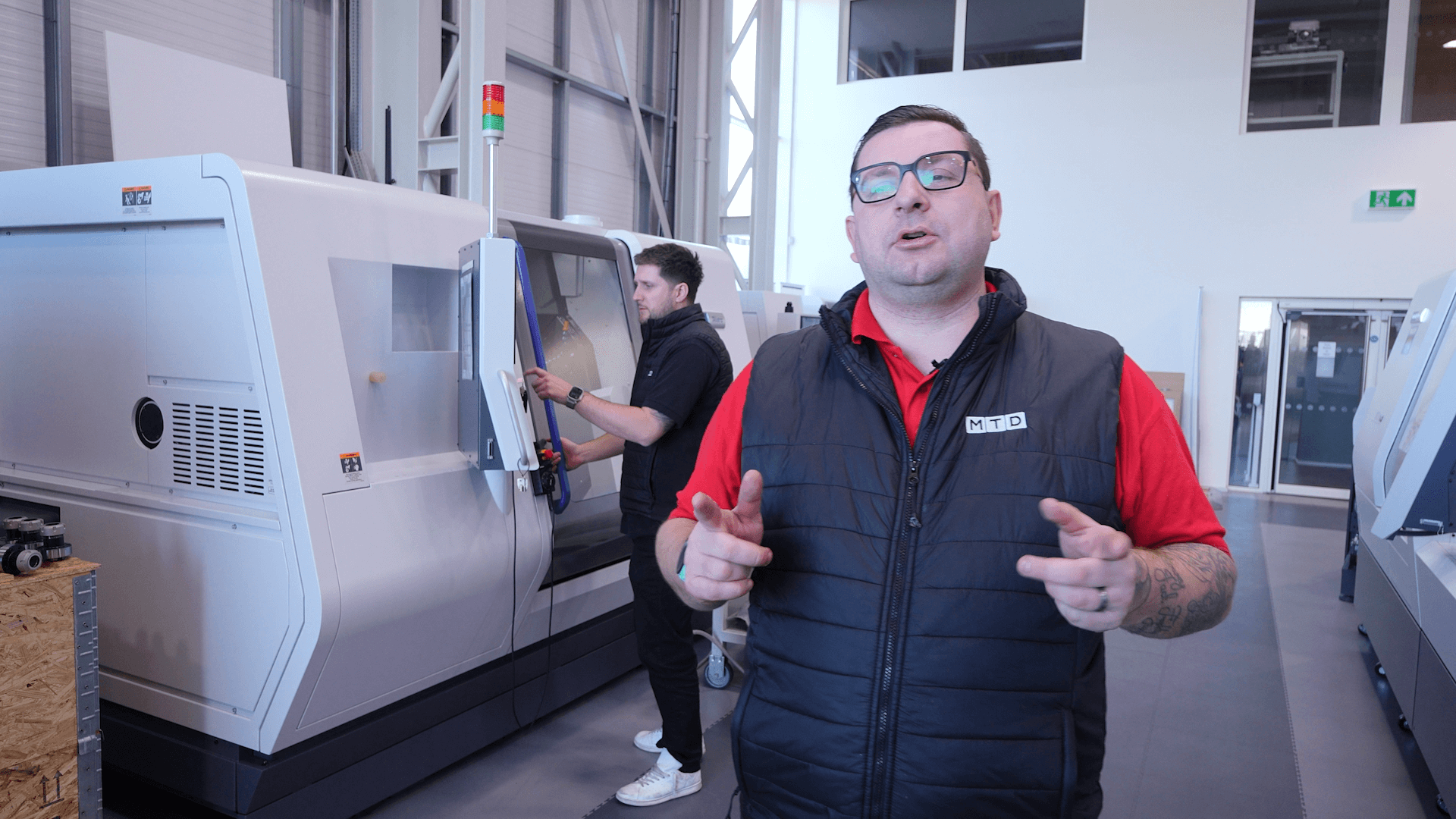

Citizen CNC’s technology plays a critical role in the success of such manufacturing operations. The Cincom L12-X and L32-XII machines are designed with precision engineering in mind, catering to complex projects like those undertaken by C & M Precision Limited.

The company’s deployment of these advanced CNC machines underscores their commitment to quality and innovation in the manufacturing sector. By maintaining focus on accuracy and reliability, C & M Precision Limited continues to exceed industry standards.

Citizen Machinery UK remains a pivotal provider of cutting-edge manufacturing solutions, empowering businesses like C & M Precision Limited to enhance their operational efficiencies and maintain a competitive edge in the precision engineering market.

View more news from Citizen Machinery UK