In the manufacturing industry, precision is paramount. However, the fragility of probes used in CNC machining makes them susceptible to damage from programming errors. Vericut UK has introduced an innovative solution to mitigate this risk with their CNC Probing Module.

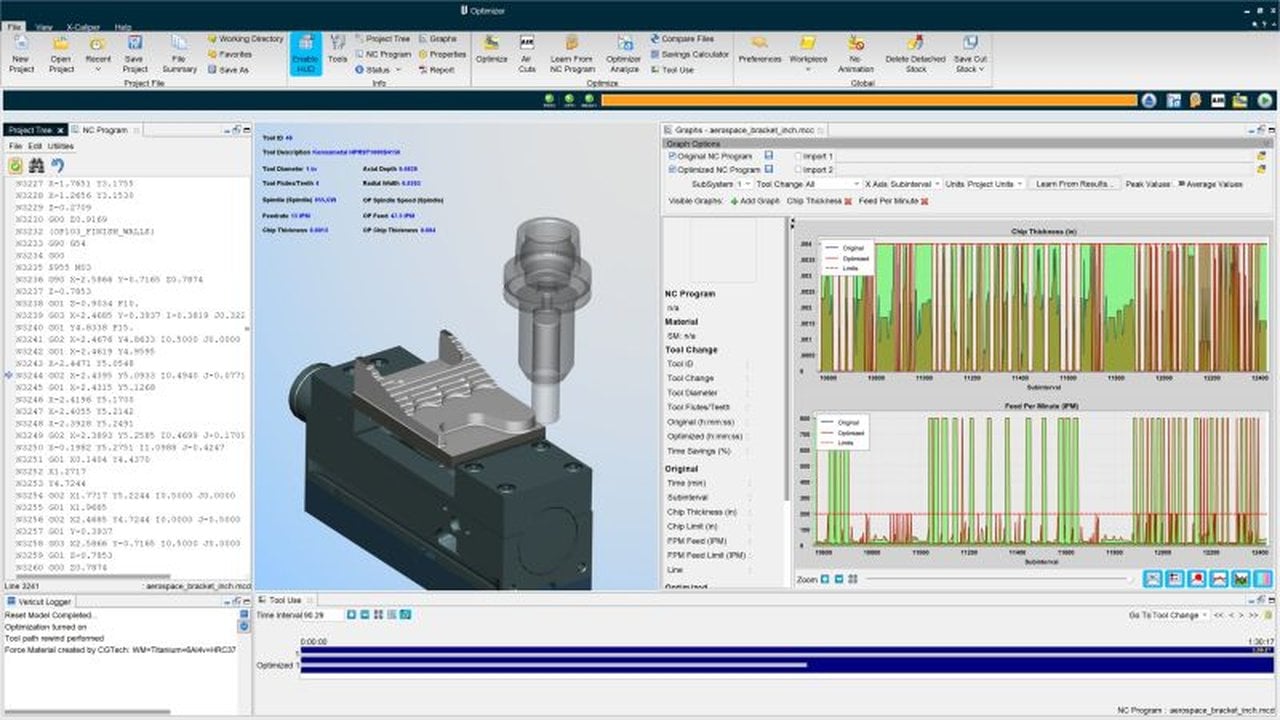

The module allows users to simulate and verify all probing routines before actual execution. This ensures that any potential errors are detected and corrected in the digital space, reducing the risk of physical damage to probe tips or spindles. The system is designed to detect collisions between the probe, the part, and the fixturing. By ensuring only the probe tip makes contact, damage to other components is effectively prevented.

This advancement is set to decrease the number of crashes and broken probes experienced by operators, thereby increasing confidence before the start of a cycle. The Vericut CNC Probing Module promises not only to protect expensive equipment but also to streamline the manufacturing process by reducing downtime associated with probe-related mishaps.

Vericut UK, a leading provider of CNC simulation software, continues to innovate in the sector, aiming to enhance precision and efficiency within the industry. Their latest probing module is a testament to their commitment to providing cutting-edge solutions that meet the evolving needs of machining professionals.

For more information, manufacturers are encouraged to explore the capabilities of Vericut’s CNC Probing Module and how it can safeguard their operations from costly errors.