Vericut, a leader in CNC machining solutions, is leading the charge in sustainable manufacturing with its latest initiative focusing on virtualized machining. In its newly released report titled “Smart Manufacturing for Sustainable Manufacturers,” Vericut outlines how its technology aids in reducing environmental impact while enhancing operational efficiency.

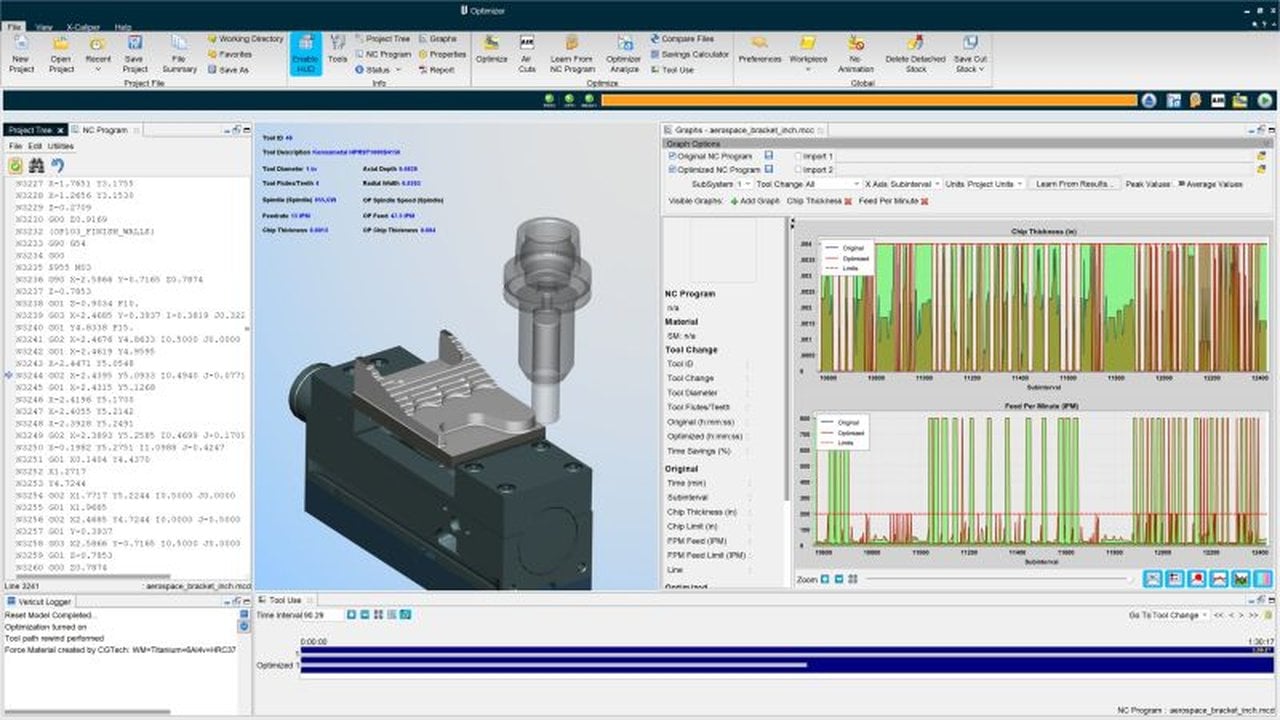

The report highlights the significance of virtualized CNC machining in promoting sustainability. By simulating and verifying processes before actual machining begins, manufacturers can significantly reduce material waste and downtime. This approach is critical in advancing efficient practices across the industry.

Vericut’s innovative cutting strategies not only lower energy usage but also extend tool life, ultimately reducing the cost per part. Such advancements are particularly important as companies face increasing regulatory and environmental constraints.

A notable feature of Vericut’s approach is the use of digital twins and virtual workflows, which facilitate better collaboration and resource efficiency. This technology is essential for manufacturers striving to make their operations leaner, greener, and more cost-effective.

For organizations looking to adapt to these changes, Vericut’s report delivers practical insights into how digital validation and optimization can bring about substantial improvements. This includes driving more responsible production practices by integrating sustainability into the core of manufacturing processes.

Vericut continues to be a pioneer in the field, demonstrating an unwavering commitment to supporting manufacturers worldwide in their journey towards sustainability.

Read this post on LinkedIn