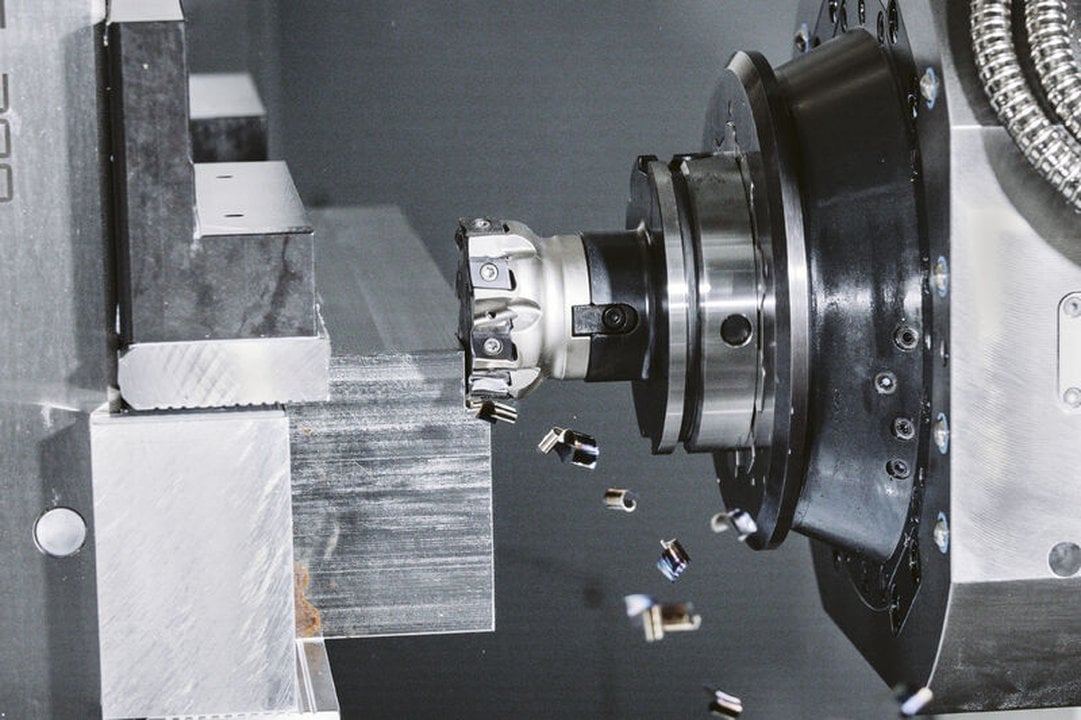

Nickel-based alloys, such as Inconel and Hastelloy, are vital in sectors including aerospace and oil and gas due to their remarkable heat resistance and durability. However, these same attributes make machining these materials particularly challenging. High cutting forces, excessive heat generation, and susceptibility to work hardening are some of the issues faced by manufacturers.

Despite these challenges, improved productivity and tool life can be achieved with the right approach. CERATIZIT, a leader in cutting tool solutions, offers valuable insights and products that address these machining complexities.

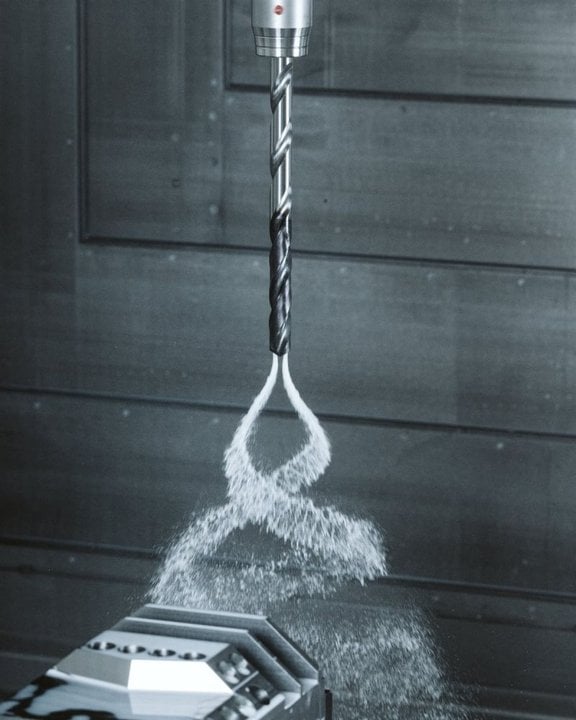

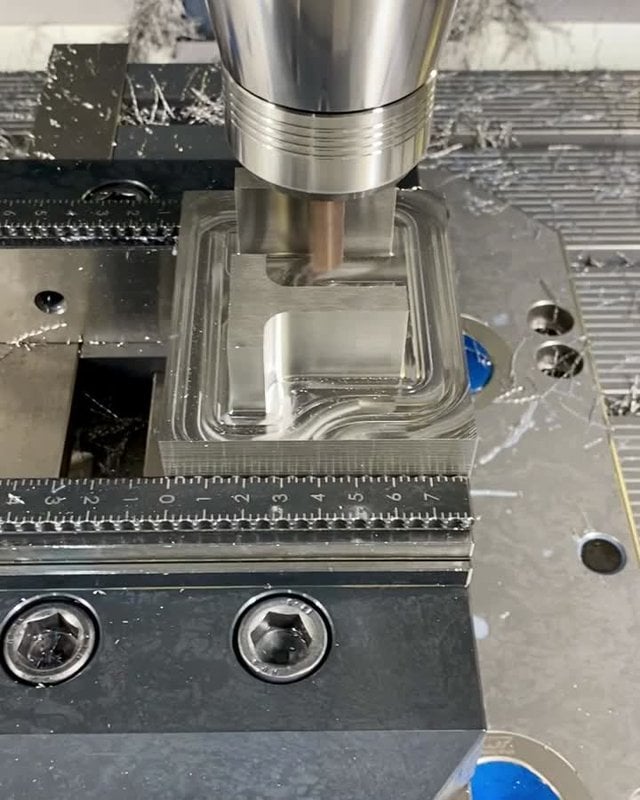

Several critical strategies are recommended for machining nickel-based alloys effectively. First, selecting the appropriate carbide substrate is essential for enhancing strength and toughness. Optimizing tool geometry can also significantly reduce heat and improve tool stability during cutting operations. Applying advanced coatings to tools can improve durability and extend edge retention.

Moreover, employing smart cutting strategies is crucial for managing heat and avoiding work hardening. Rigid machine tools and toolholders are essential to minimize vibration, thereby improving precision and tool life.

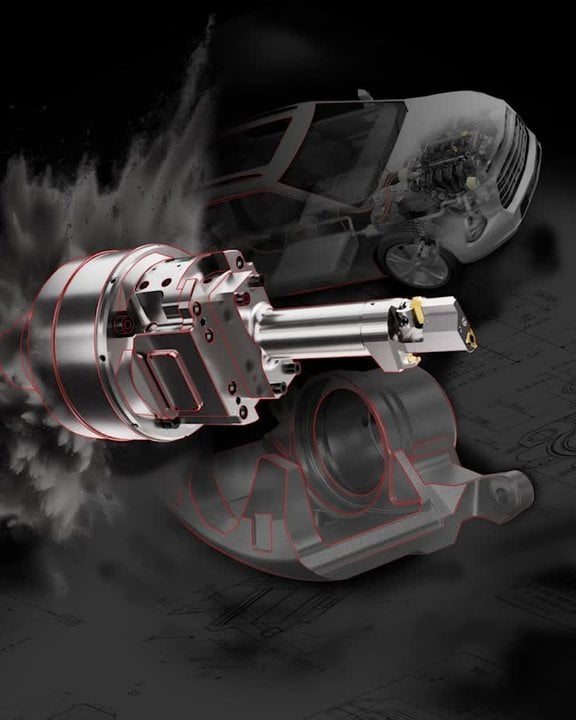

CERATIZIT provides a range of solutions designed specifically for machining these superalloys, ensuring manufacturers can maintain efficiency while overcoming inherent challenges. Their comprehensive range of products, including carbide tools and advanced coatings, are tailored for the demands of such high-performance materials.

For further insights and detailed guidance on machining nickel-based alloys, CERATIZIT offers additional resources and articles to explore.

Read this post on LinkedIn