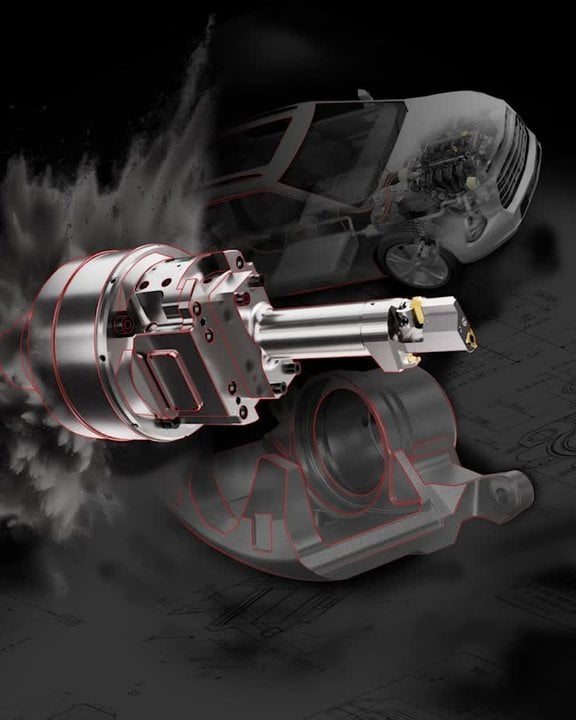

CERATIZIT has introduced the MonsterMill ISO-S, a cutting tool designed to conquer the challenges of machining ISO-S materials, such as titanium and nickel alloys. Engineered to withstand extreme conditions, this tool aims to enhance manufacturing efficiency and precision.

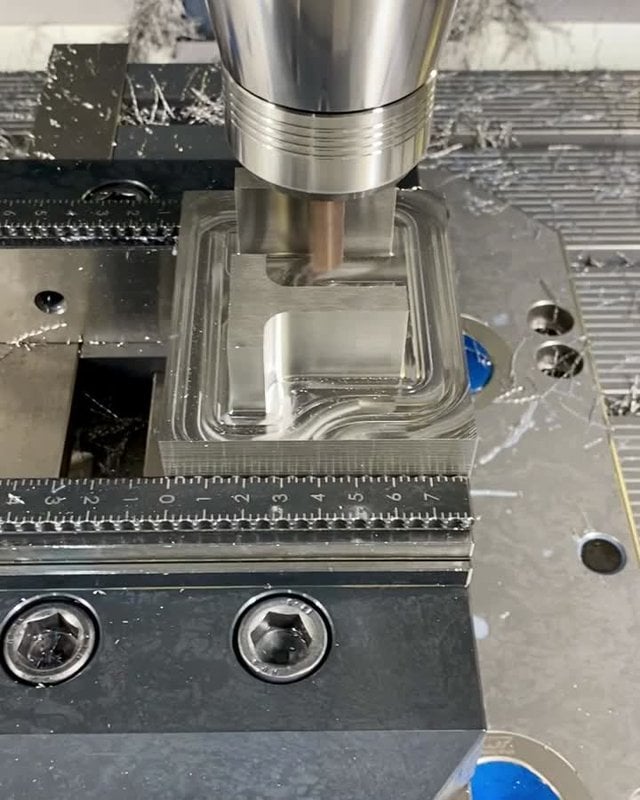

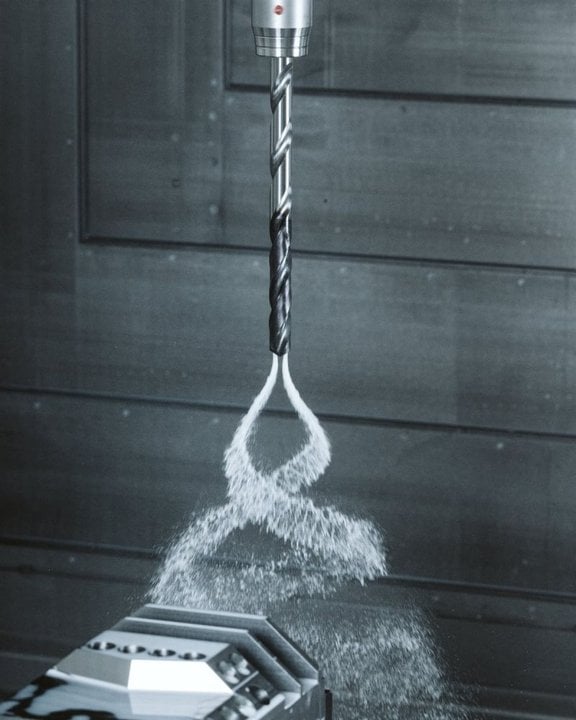

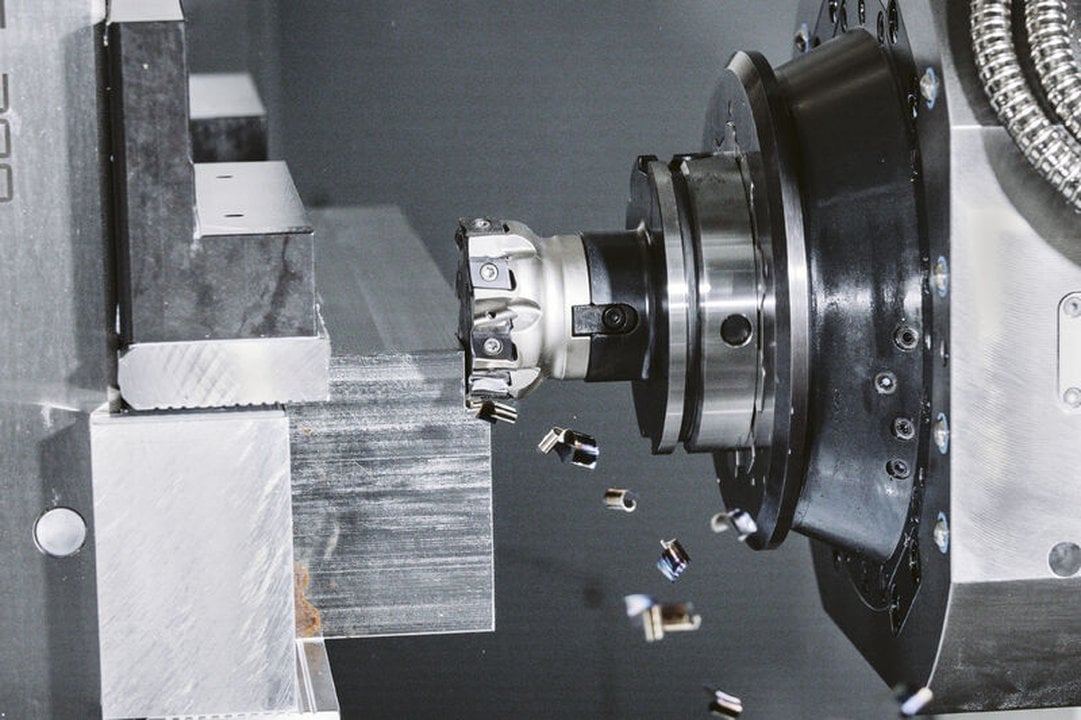

The MonsterMill ISO-S features the Dragonskin DPX22S coating, which enhances thermal stability and wear resistance, essential for high-demand environments. Its smart edge geometry reduces vibration and improves surface finish, while the optimised chip evacuation ensures maximum process reliability.

Available in 4-, 5-, and 6-flute versions, the MonsterMill ISO-S covers diameters ranging from 3 to 20 mm, with corner radii from 0.2 to 5.0 mm. For manufacturers with specific needs, custom dimensions are available on request, providing versatility and customisation in tooling specifications.

This development solidifies CERATIZIT’s position as a leader in high-performance machining solutions. By addressing the complex requirements of machining difficult materials, they continue to support industries where precision and durability are paramount.

CERATIZIT is gaining recognition for its commitment to innovation in the manufacturing industry, offering cutting-edge tooling technologies that address some of the toughest challenges faced by engineers today.