Increasing productivity in manufacturing doesn’t always require investing in new machines or automation. A frequently overlooked yet effective method is optimizing workholding solutions.

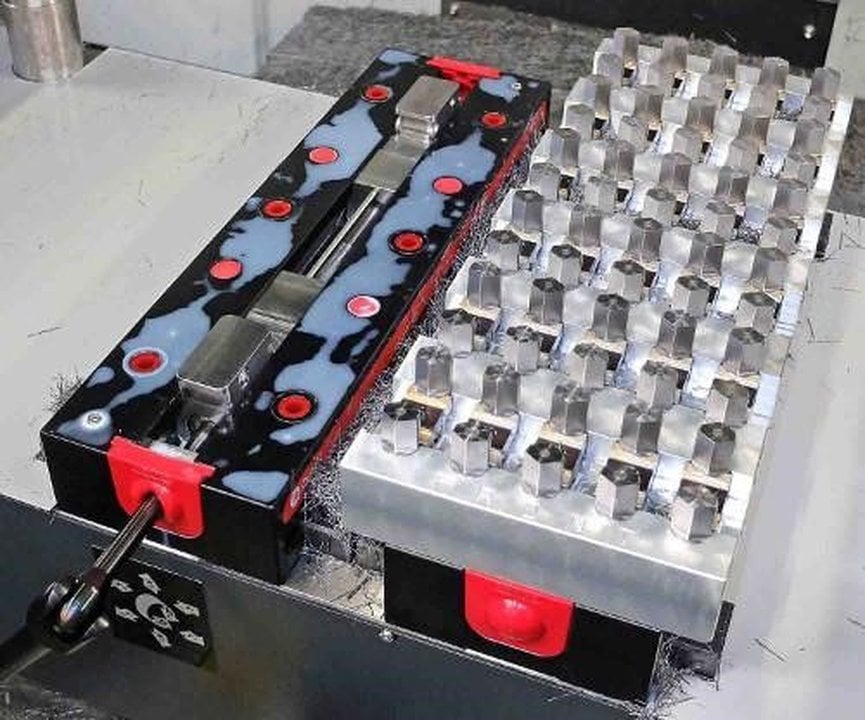

Workholding, the equipment used to secure a workpiece, plays a crucial role in manufacturing efficiency. The right workholding solution can significantly enhance cycle times, repeatability, and part quality. By minimizing setup time, improving rigidity, and increasing process confidence, effective workholding allows machines to reach their full potential.

Upgrading workholding systems offers a quicker and more cost-effective way to achieve productivity gains compared to purchasing new machinery. This strategy not only provides immediate impacts on productivity but also boosts overall quality.

For manufacturers seeking to maximize the performance of their existing machinery, it may be worthwhile to reassess how parts are held during production. Effective workholding solutions enable operators to streamline processes, thus enhancing output and product quality without the need for significant capital investment.

1st Machine Tool Accessories, a leader in providing top-tier workholding solutions, highlights the importance of investing in proper workholding systems tailored to specific manufacturing needs. Their expertise and innovative products help manufacturers around the globe improve their operational efficiency.

In conclusion, by focusing on optimizing workholding solutions, manufacturers can enhance productivity and quality, proving that sometimes the most impactful changes come from within existing operations.

View more news from 1st Machine Tool Accessories