- Newsas

Starrag Launches Custom Machining Solutions with Carbide Tooling

Starrag, a leader in high-precision engineering solutions, has announced a new initiative offering bespoke manufacturing solutions complemented by expertly matched solid carbide tools. Designed to enhance productivity and precision, the tools are specifically tailored to meet the varied needs of m…

MTDCNCLast viewed

MTDCNCLast viewed - Eventna

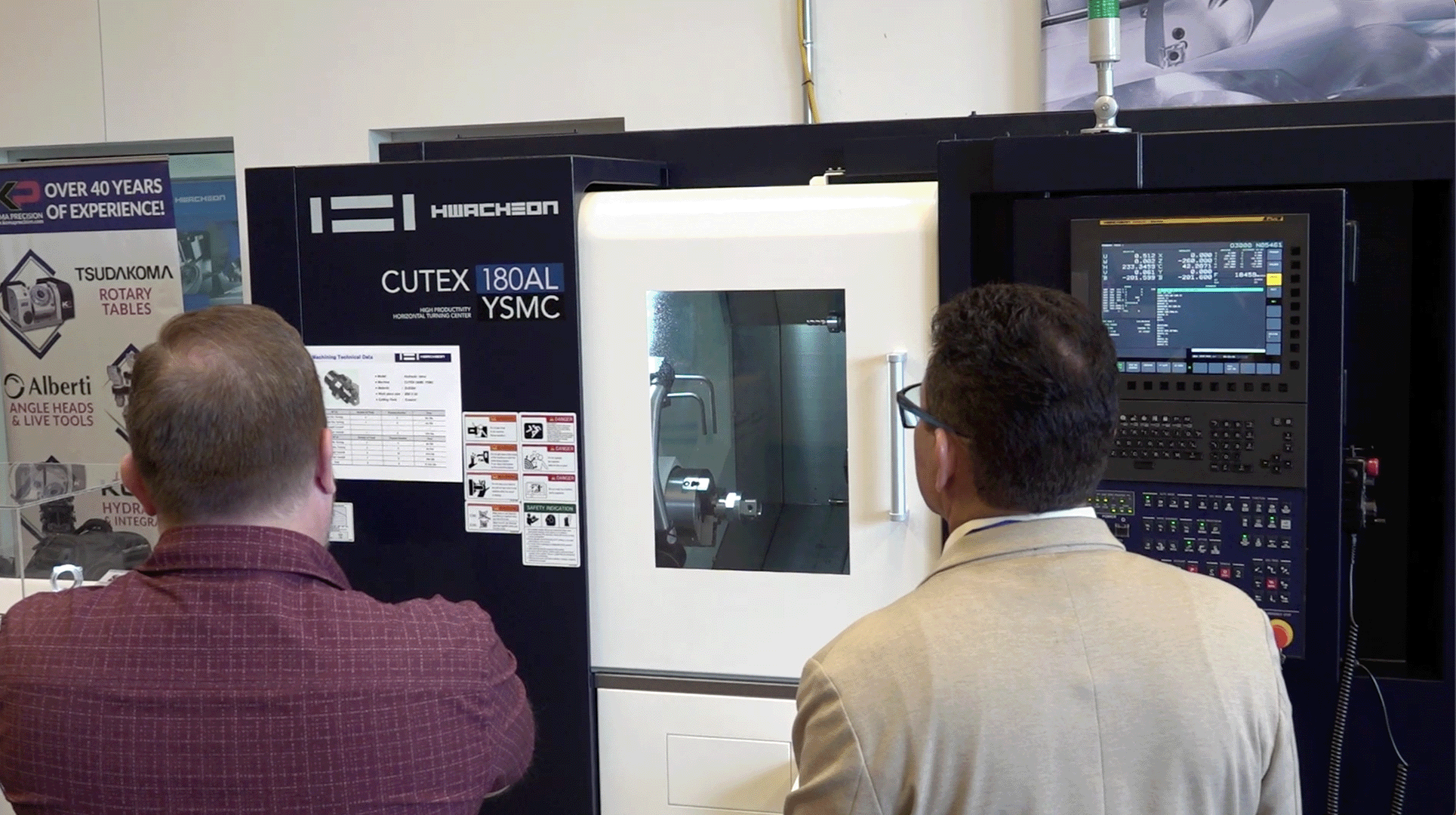

Day 1 Highlights: Okuma America Corporation Machine & Automation Fair

Day 1 of the Okuma America Corporation Machine and Automation Fair set a powerful tone for the week, delivering excitement, innovation, and an impressive turnout. With nearly 700 visitors filling both buildings, the energy on site has been electric—clearly reflecting the industry’s growing momentu…

Arthur FieldLast viewed

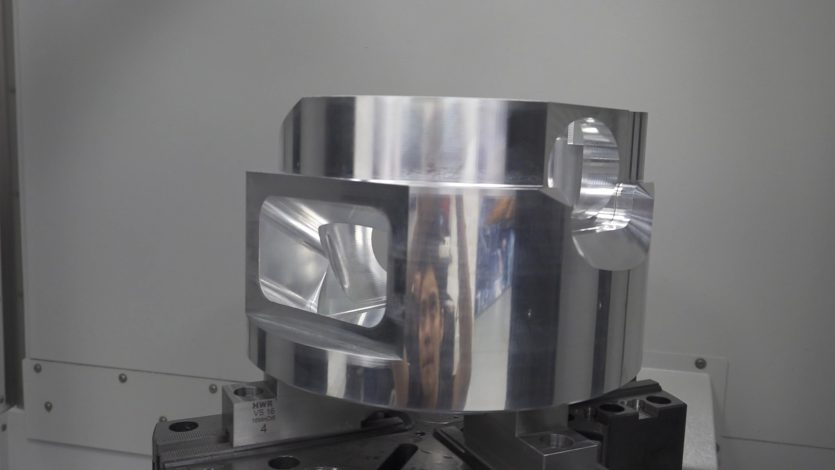

Arthur FieldLast viewed How is a part like this even possible?

When partners like Starrag and Pokolm team up, precision machining reaches a new level. At Starrag HQ, Pokolm’s Bill Upchurch and Starrag’s James Stolo show how the right combo of tooling and machine can take a part from raw aluminum to mirror finish, and handle tougher aerospace alloys too. Using…

MTDCNCLast viewed

MTDCNCLast viewed - Newsna

New Adapters Revolutionize Aerospace Machining

In a significant advancement for the aerospace manufacturing sector, a leading company has introduced innovative CV and CVKV adapters. These adapters are specifically designed to enhance high-speed machining capabilities, ensuring precision and efficiency. The newly launched adapters cater to a va…

MTDCNCLast viewed

MTDCNCLast viewed

NA

Popular North America

Omax Maxiem X Series Waterjet Machines Deliver Higher Performance, Smarter Operation and Versatile Cutting Capabilities!

Hypertherm Associates has expanded its waterjet cutting portfolio with the Omax Maxiem X Series JetMachining Centers, engineered to deliver high-performance abrasive waterjet cutting with greater precision, improved usability and enhanced workflow flexibility. Designed to cut intricate geometries across a wide range of materials — including metals, plastics, stone, ceramics, glass and composites — the Maxiem X Series allows many parts to achieve surface finishes that often eliminate secondary machining. Developed for shops seeking intelligent performance at a cost-effective investment, the Maxiem X Series integrates upgraded hardware and software features that transform both efficiency and user experience. Among its standout advancements

Ashutosh AroraLast viewed

Ashutosh AroraLast viewed

Emuge-Franken Expands Self-Lock Threading Tools for Safety-Critical Applications!

Emuge-Franken USA has significantly expanded its Self-Lock Threading Tools Line, introducing a broader range of advanced solutions engineered for industries where precision, reliability, and safety are paramount. The enhanced lineup now includes fourteen new 2×D Threads-All/AERO Thread Mills ranging from #5-40 to 1″-12, along with thirty newly introduced 3×D thread mill sizes from #2-56 to 1″-12. This marks the first time Emuge has offered extended-reach 3×D options within its Self-Lock portfolio, giving manufacturers greater flexibility for deep or hard-to-access threading applications. In addition to the cutting tool expansion, Emuge has strengthened its inspection capabilities with the extension of its High

Ashutosh AroraLast viewed

Ashutosh AroraLast viewed

WALTER Surface Technologies Acquires HERMES North America, Expands Leadership in Coated Abrasives and Automation Solutions!

WALTER Surface Technologies has announced the acquisition of HERMES North America, a respected supplier of coated abrasives, marking a strategic move that strengthens WALTER’s position across key finishing, robotic and automation-driven applications. The acquisition is set to ensure long-term stability for HERMES customers and employees while significantly enhancing WALTER’s already extensive abrasive solutions portfolio. According to Marc-André Aubé, CEO of WALTER Surface Technologies, the acquisition represents a forward-looking investment aligned with growing customer demand for automation and productivity. “This acquisition is a long-term investment in growth and innovation as customers continue to automate their processes,” Aubé stated. He added that

Ashutosh AroraLast viewed

Ashutosh AroraLast viewed

New Adapters Revolutionize Aerospace Machining

In a significant advancement for the aerospace manufacturing sector, a leading company has introduced innovative CV and CVKV adapters. These adapters are specifically designed to enhance high-speed machining capabilities, ensuring precision and efficiency. The newly launched adapters cater to a variety of tooling needs, including shell mill, screw-on, and shrink fit options. Their extended gauge lengths are particularly beneficial for manufacturers, allowing greater adaptability without the need for cumbersome inch-to-metric conversions. This adaptability significantly broadens compatibility with metric tool systems, a critical requirement in many global manufacturing operations. These adapters promise reliable performance under demanding conditions, making them ideal for

MTDCNCLast viewed

MTDCNCLast viewed

Manufacturing Firms Urged to Act on Section 179 Savings

Manufacturers are being reminded of the impending deadline to benefit from the 2025 Section 179 tax savings, offering an opportunity that should not be missed. Companies are encouraged to purchase equipment before the end of the year to take full advantage of the deduction, which now has increased limits. For 2025, businesses can capitalize on deduction limits raised to $2.5 million. This comes with a phase-out threshold beginning at $4 million, reaching complete phase-out at $6.5 million. In addition, bonus depreciation has been reinstated at 100% for qualifying assets acquired after January 19, 2025. This tax incentive aims to support

MTDCNCLast viewed

MTDCNCLast viewed

Find the right tools in 90 seconds or less?!

Stop guessing which tool fits the job. Ceratizit’s ToolSelect finds it for you instantly! Upload a 3D model, compare ranked tool options, and order everything directly. In this quick tour, Tom Skubala of MTDCNC and Manuel Bergmann of Ceratizit break down the smarter way to choose tooling.

Tom SkubalaLast viewed

Tom SkubalaLast viewed What We Do

Your partner for marketing, media, and events in manufacturing.

Upcoming Events

See what’s coming up and join us on the road.

9–10 December 2025

9 – 10 December | Okuma | Charlotte

Experience the Possibilities Time is ticking to see firsthand how Okuma machines and automation technologies transform manufacturing. At the Okuma Machine & Automation Fair, our machines and technologies are available for full display and demonstration. See for yourself what our innovations can do for you.

6–7 May 2026

6 – 7 May | Greater Chicago Design 2 Part Show | Schaumburg

The Design-2-Part Trade Show is the ideal marketing opportunity for contract manufacturers and job shops in the metal, plastics, rubber, electronics, and finishing industries. How We Promote We use several different methods of direct marketing that target qualified OEM engineers and buyers looking for manufacturing services. This includes:

20–21 May 2026

Greater Denver Design-2-Part Show | Denver | 20 – 21 May

The Design-2-Part Trade Show is the ideal marketing opportunity for contract manufacturers and job shops in the metal, plastics, rubber, electronics, and finishing industries. How We Promote We use several different methods of direct marketing that target qualified OEM engineers and buyers looking for manufacturing services. This includes:

14–18 September 2026

IMTS | Chicago | 14 – 19 September

The Largest Manufacturing Show in the Western Hemisphere As the largest trade show in the Western Hemisphere, IMTS – The International Manufacturing Technology Show draws the innovators, sellers, and drivers of manufacturing technology together to connect, be inspired, and find new solutions. Looking for more information on all things IMTS 2026? You’ve come to the right place. Are you exhibiting at this event, and want MTDCNC’s support? Fill in the form and one of our team will be in touch to see how we can help you make the most of exhibition!

Podcast

Here at MTDCNC, you’ll find a collection of top-notch podcasts featuring discussions and insights from the manufacturing market.

What’s the difference between a supplier and a partner?

They don’t just sell a machine and drop it on your shop floor — Starrag runs the entire journey as a full project. In this MTDCNC podcast, Arthur Field sits down with Udo and John of Starrag to unpack how the company delivers almost 24/7 cross-continental project management, structured kick-off meetings, and deep technical support. With around 70% of their North American business in defence and ITAR and over 70 machines supporting programs like the F-35, Starrag brings the engineering strength to handle everything from tooling and turnkey programming to massive foundations. Tune in to learn how Starrag becomes a

They’re bringing BIG updates to the North American market!

From compact series machines and powerful five-axis platforms to the revolutionary Matrix Tool Magazine holding up to 828 tools, Starrag is delivering complete solutions for the shop floor. MTDCNC’s Arthur Field sits down with Udo Herbes and Jim Stolo at Starrag’s Kentucky HQ to unpack everything new for the North American market: RCS CAM software, more hands-on factory training for service techs, expanded support across North America and Mexico, and more. If you’ve ever wondered what it takes to keep high-end manufacturing ahead of the curve, this MTDCNC podcast with Starrag is one you can’t miss! Interested in hearing some

The Best Investment You’ve Never Heard Of: Why MEP Is Saving U.S. Manufacturing!

Quietly operating in the background of American manufacturing is one of the nation’s most effective programs, NIST’s Manufacturing Extension Partnership (MEP). Designed as a public–private network, MEP helps small and medium-sized manufacturers modernize operations, embrace technology, and compete in a global economy that’s changing faster than ever. While large corporations often have access to consultants, engineers, and global supply chains, smaller manufacturers typically work with tighter budgets, limited expertise, and far less time. That’s where MEP steps in. With a nationwide network of nearly 1,400 experts and thousands of affiliated organizations, the program connects manufacturers of every size and specialty

Simpler setups, tougher grades, and a $4,000 tooling prize? Yes please.

Steel, stainless, or high-temp alloys—what if you didn’t need a dozen insert grades to cover it all? In this MTDCNC Podcast, Greg Sage of Kennametal joins MTDCNC’s Arthur Field to reveal why the KCP25C, KCU, and KCS10B turning grades are reshaping how job shops approach productivity. From edge-holding coatings that stay sharp under pressure to inserts built for longer life and consistent performance, it’s all about cutting costs while keeping the spindle turning. Oh, and stick around—because Kennametal is giving away a custom $4,000 toolbox packed with holders, inserts, and even a voucher for more tooling!

Get a Grip on the Future!

Lights, mic check, action! We’re thrilled to announce that on this episode of The Gunn Show, we’ll be welcoming Dean Winkel as the special guest. If you’ve ever been curious about precision, gripping systems, or how engineering meets real-world performance, this episode is going to be one for the books. Who Is Dean Winkel? Dean is a standout in the realm of mechanical engineering / industrial applications. His passion lies in bridging the gap between theory and hands-on application, making complex systems elegantly efficient. Whether he’s optimizing a gripper design, tackling challenges in automation, or unlocking performance gains for clients,

The KIDS are Taking Over the SHOW!

In this episode of The Gunn Show, Joni Cunningham brings her kids on stage to share their story and perspectives of manufacturing. This is one of the most joyous podcasts that Tony has ever hosted, as you can tell by the constant smiles and jokes. If this is what the future looks like, we are in good hands!