🎧Mitutoyo delivers missing link

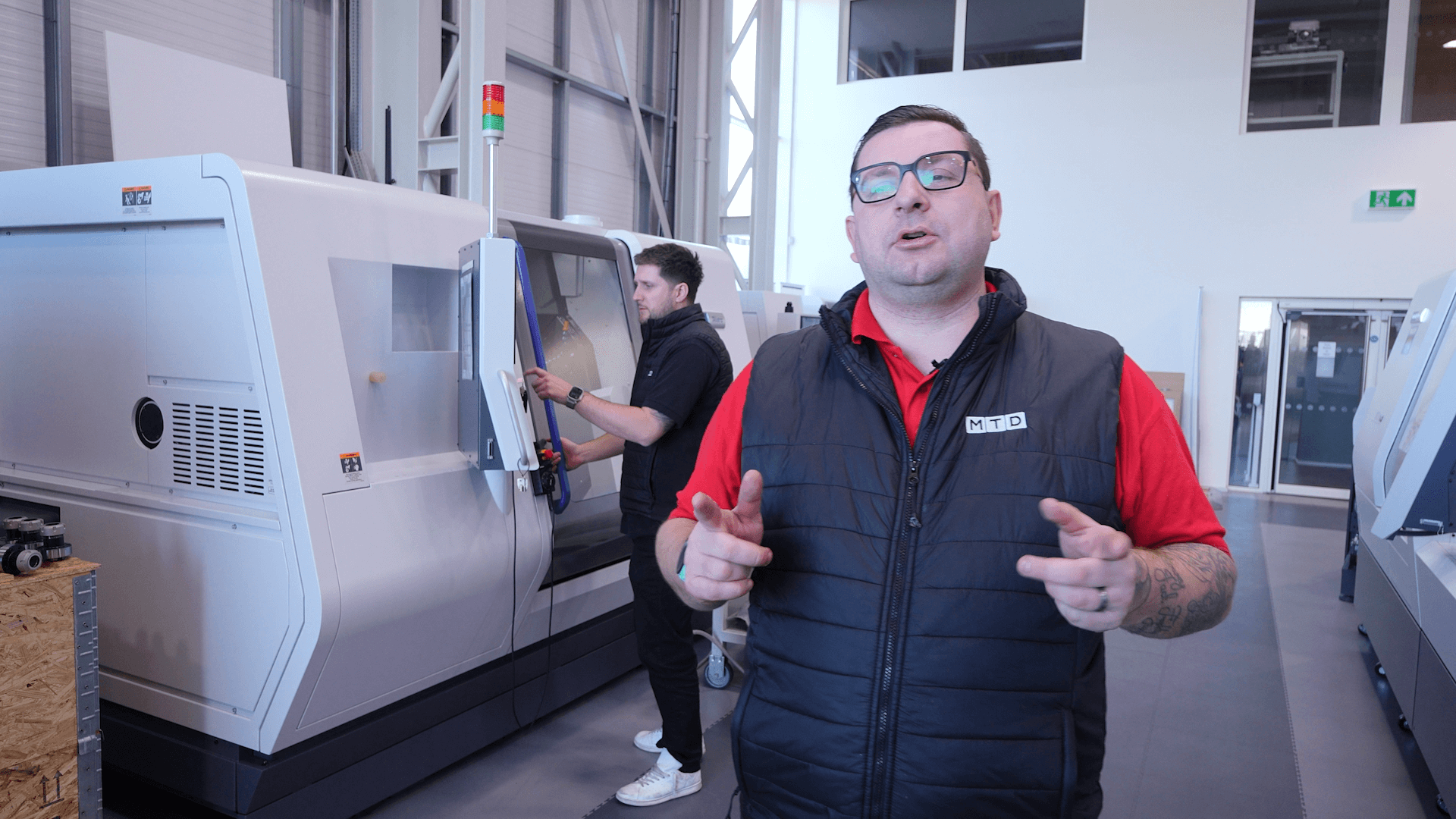

As a globally recognised manufacturer of leaf chains, FB Chain products are used in the automotive, material handling, and industrial machining sectors. The Letchworth Garden City company has earned a reputation for producing durable high-performance chains that support critical operations in demanding environments. To further this commitment, the company employs equipment from Mitutoyo.

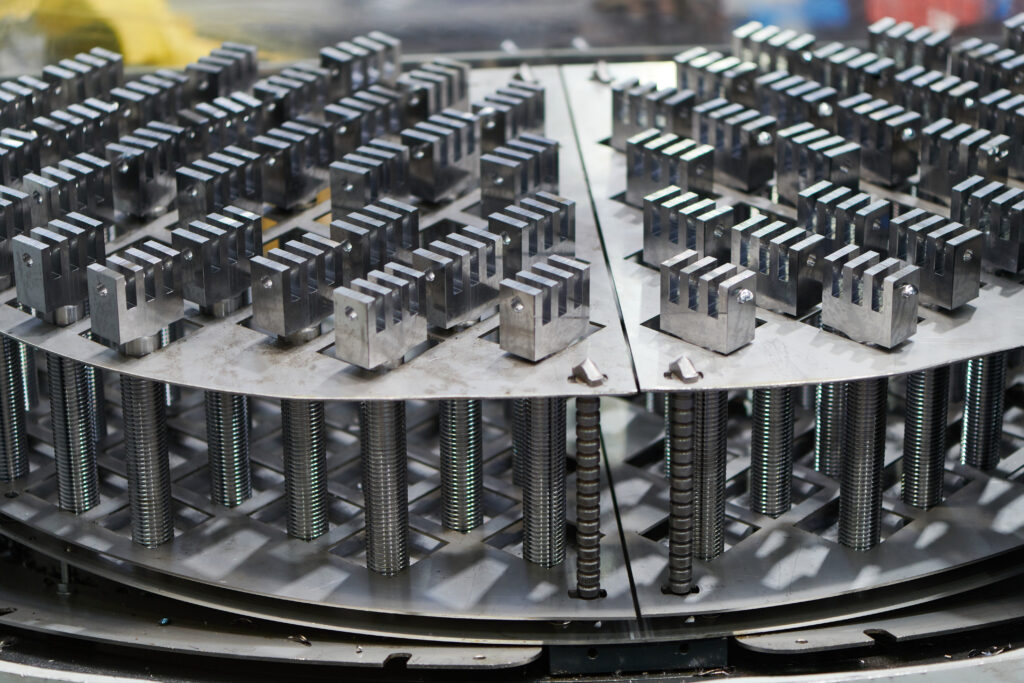

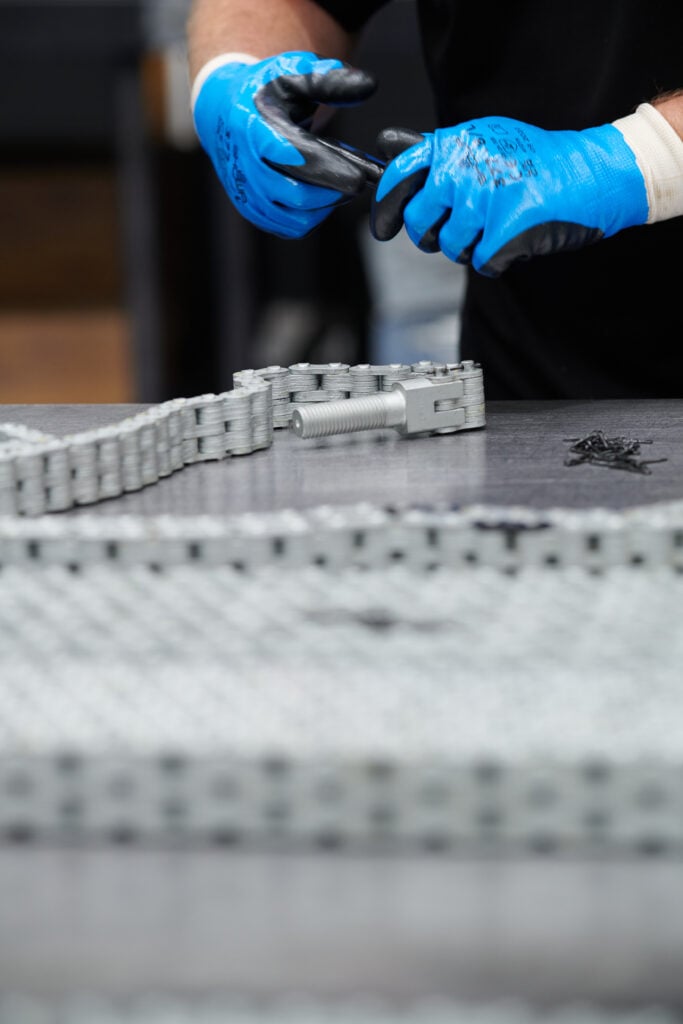

The product range includes leaf chains, roller chains, anchor bolts, sprockets, and customised chain solutions. The company’s leaf chain kits include pre-measured components like chains, bolts, and attachments. FB Chain’s dedication is supported by a continuous partnership with Mitutoyo, which has been vital in maintaining the highest quality control.

With production volumes rising and the demand for tighter tolerances increasing, the need for faster and more automated measurement processes became essential. The company sought a solution that would enhance measurement accuracy while ensuring components were within the required tolerances.

FB Chain approached Mitutoyo for their Roundtracer Flash, an advanced, non-contact measurement solution. This optical measurement system is perfect for inspecting the intricate surface profiles and geometries of the produced anchor bolts and pins. The Mitutoyo Roundtracer Flash enables FB Chain to measure dimensional accuracy and geometric consistency down to microns. Additionally, the Roundtracer Flash provides precise process control for demanding customers.

The strong partnership between FB Chain and Mitutoyo was crucial in implementing the Roundtracer Flash system. Chris Cook, the Operations and Manufacturing Manager at FB Chain, visited Mitutoyo’s Coventry site, where he received invaluable experience and support from Mitutoyo, collaborating closely to customise the measurement processes and integrate the Roundtracer Flash into the existing production line.

Discussing this, Chris Cook stated: “Bigger customers require more accurate results, and we knew Mitutoyo could cover the range we were looking for. We sought a machine that would be easy to implement and provide static and dynamic measurements for our anchor bolts, blocks, and pins.”

With a Mitutoyo hardness tester, small tools, and gauges already in use at the facility, Chris and his team continued the Mitutoyo synergy while searching for a shop floor measuring machine. Aiming to operate 24/7, FB Chain has set an ambitious production target of 168 hours per week. It is eager to determine if this is achievable when considering measurement and loading/unloading times.

With more accurate and consistent measurements from the Roundtracer Flash, FB Chain can assess tool life limits, contributing to the 168-hour production target with increased unmanned working hours. With demand rising, FB Chain processes 25 to 30 tonnes of steel monthly. With 97% of manufacturing conducted in-house, their automated machining is being maximised to meet customer demands, necessitating the deployment of a high-priority, non-contact measuring machine. Initially, the Roundtracer Flash will be manually loaded, but as production increases, FB Chain intends to integrate another robot arm.

After installing the Roundtracer Flash, Chris remarked: “The machine is user-friendly, interacts well, and has enhanced measurement efficiency. We already had trust in Mitutoyo, but observing the performance of the Roundtracer Flash and its extensive capabilities has further validated our continued reliance on Mitutoyo products.”

With some initial guidance, both operators and inspectors can effectively use the machine. The speed of the Roundtracer Flash improves inspector efficiency by 97.5%, reducing a 10-minute inspection to just 15 seconds. Furthermore, the number of measurements has increased, enabling comprehensive dimensional checks during every batch. Not only is it capable of measuring cylinders, round parts, and turned components, but the machine has also been further programmed to assess milled flat surfaces and hole diameters/alignments. The Roundtracer Flash revealed that previous measurement methods using hand tools did not meet the requirements of specific customers, demonstrating that eliminating human error from the process has enhanced the inspection process.