🔊Intelligent software delivers safer manufacturing

In 2018, Whiston Industries Ltd invested in Tebis CAD/CAM software to transform their manufacturing processes. The software has played a key role in increasing machining productivity, enabling accurate toolpath simulations, and ensuring machine collision avoidance. With prestigious customers including Jaguar Land Rover, Aston Martin, and Audi, the third-generation family business has made efficiency and quality their competitive advantage.

Established in 1963, Whiston Industries Ltd is a world-class engineering company supplying press tooling and metal pressings to the automotive, aerospace, renewable energy and associated markets. The company supplies the world’s leading automotive OEMs and tier-one suppliers with press tooling that demands absolute precision and reliability.

Whiston Industries made a strategic investment in Tebis CAD/CAM software to optimise their manufacturing processes, purchasing two Parpas machines alongside five Tebis software licences.

Andrew Whiston, Managing Director, explains: “To stay ahead of the competition, we have focussed on strategic investments and operational efficiency. This investment has significantly improved our machining accuracy and production times, enabling us to deliver high-quality components to our customers.”

The implementation of Tebis software introduced a new level of safety, consistency, and efficiency. The software’s powerful automation and simulation tools have enabled the company to reduce manual errors and optimise machine usage.

More Than Just Software

Paul Scally, Site Manager from Tebis UK, explains that Tebis offers far more than traditional CAD/CAM capabilities: “Our software delivers powerful CAD/CAM capabilities, consultancy and implementation services, as well as training to optimise our customer’s environment.”

Andrew emphasises how the software has become fundamental to their operations: “CAD/CAM software has proven optimal for maximising the performance potential of our machines. It allows us to fully utilise machine capacity, improve efficiency, and reduce production time. The precision ensures consistently high accuracy, critical for meeting our strict quality standards.”

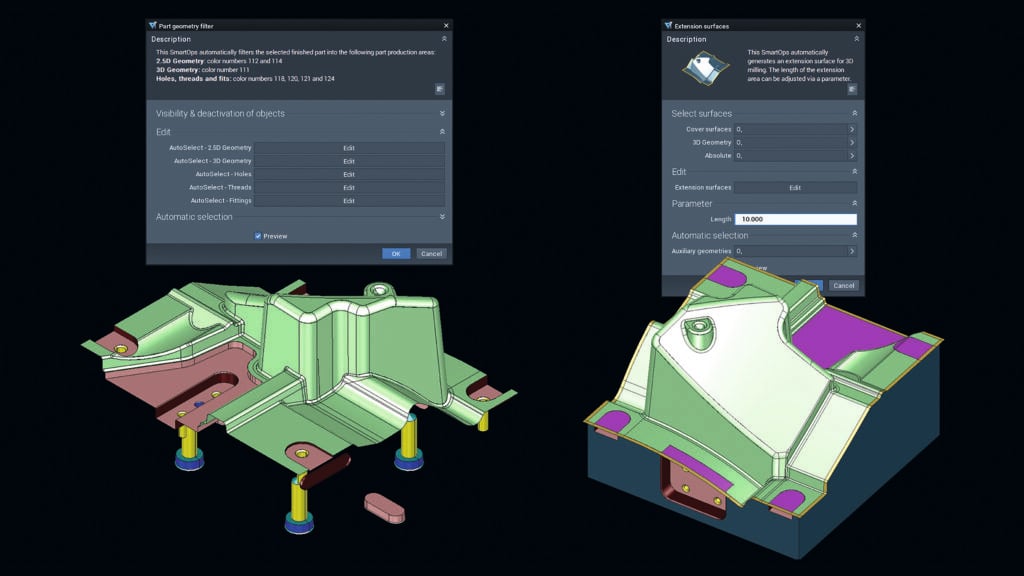

One key advantage is the automation of CAD/CAM workflows, enabling smart and intelligent manufacturing. Andrew explains: “We can build the whole manufacturing environment into Tebis. The software creates the complete digital twin—not just the machine, but the full manufacturing environment.”

This digital twin capability has transformed their approach to manufacturing. By creating a complete virtual representation of machines, fixtures, tooling, and workholding, Whiston Industries can simulate and verify every operation before it reaches the shop floor, eliminating costly collision risks.

Lights-Out Manufacturing with Complete Confidence

Tebis software reliability has enabled true lights-out manufacturing—essential when producing large, complex press tooling components for premium automotive manufacturers.

“The Tebis software is extremely reliable, eliminating concerns about unexpected machine movements,” Andrew confirms. “Knowing the software anticipates and avoids potential collisions means we can run operations with complete confidence. Engineers can run both upper and lower die machine beds simultaneously and run programmes continuously—day and night. This automation has significantly increased productivity and ensures the workshop operates at full capacity.”

Surface finishing is critical in press tooling manufacture, as any imperfections replicate in every pressed component. Whiston Industries utilises Tebis’s specialised capabilities to achieve exceptional finishing results.

Paul Scally elaborates: “Whiston Industries also uses a specialised laser package. Our software enables toolpath creation that manipulates head positions to avoid collisions and optimise machining vectors, eliminating unnecessary head movements. Tebis can adapt these toolpaths with path correction in areas where we need to change the contour without changing the data.”

This flexibility is invaluable in the press tool business, where design modifications are common. Adjusting toolpaths without returning to the original CAD data saves considerable time and maintains consistency.

Measurable Business Impact

The automation capabilities within Tebis have enabled Whiston Industries to standardise processes and embed best practices throughout operations, ensuring consistent quality regardless of which engineer programmes a particular job.

Andrew Whiston concludes: “Overall, the adoption of Tebis CAD/CAM has led to measurable improvements in productivity, cost savings, product quality and positioning the business to better meet customer demands and stay competitive in the market.”

For a third-generation family business competing globally and supplying prestigious automotive brands, the combination of strategic machinery investment and intelligent manufacturing software has proven the key to sustained competitive advantage.