Zoller to Showcase Cutting-Edge Automation and Tool Management Technologies at IMTS 2024

Zoller Inc. is set to unveil its latest innovations in automation and tool management at IMTS 2024, headlined by the introduction of the CoraMeasure LG automated tool measurement system. This state-of-the-art system is designed to provide manufacturing companies with precise, consistent measurement results, significantly enhancing process reliability and productivity, while also addressing workforce shortages.

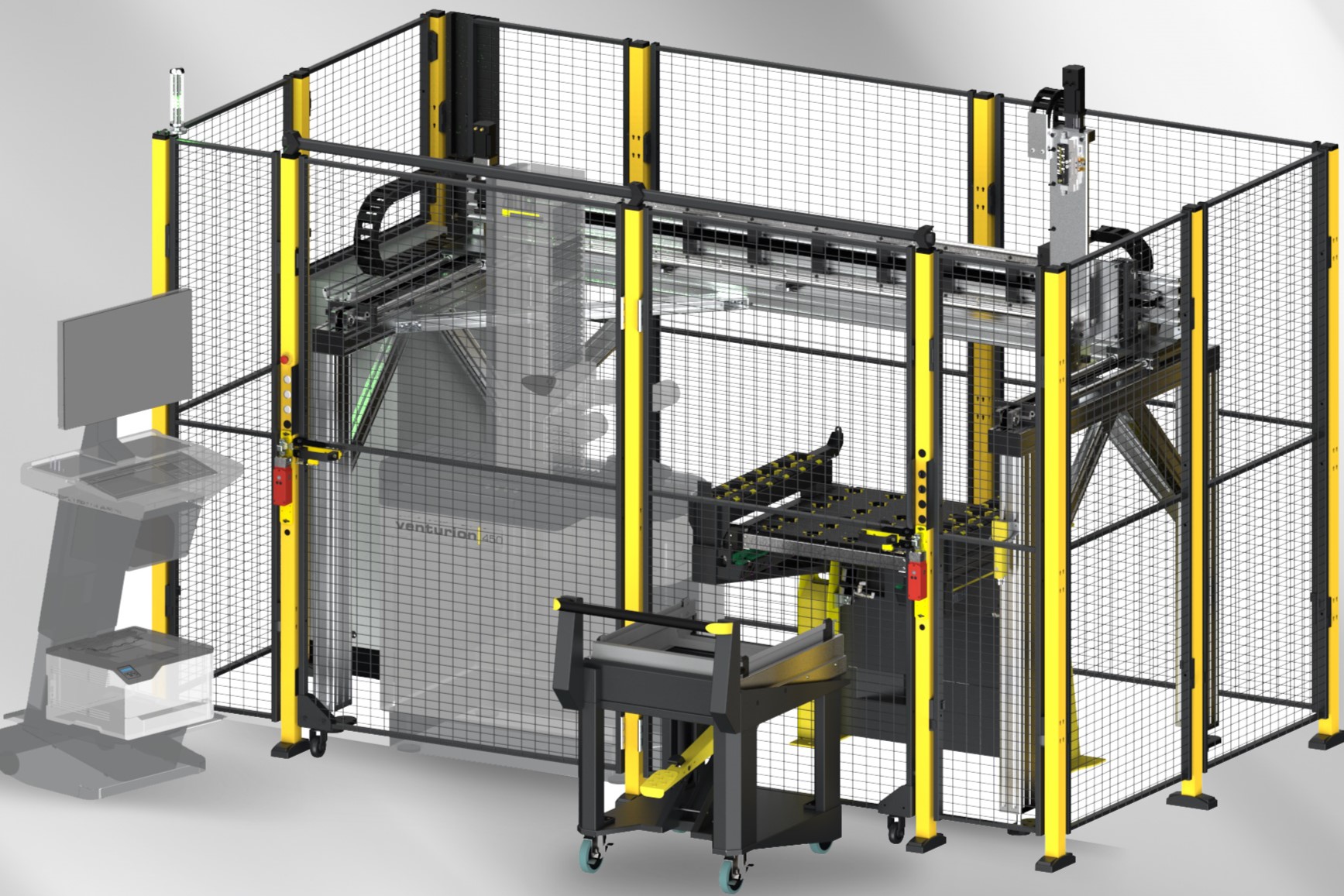

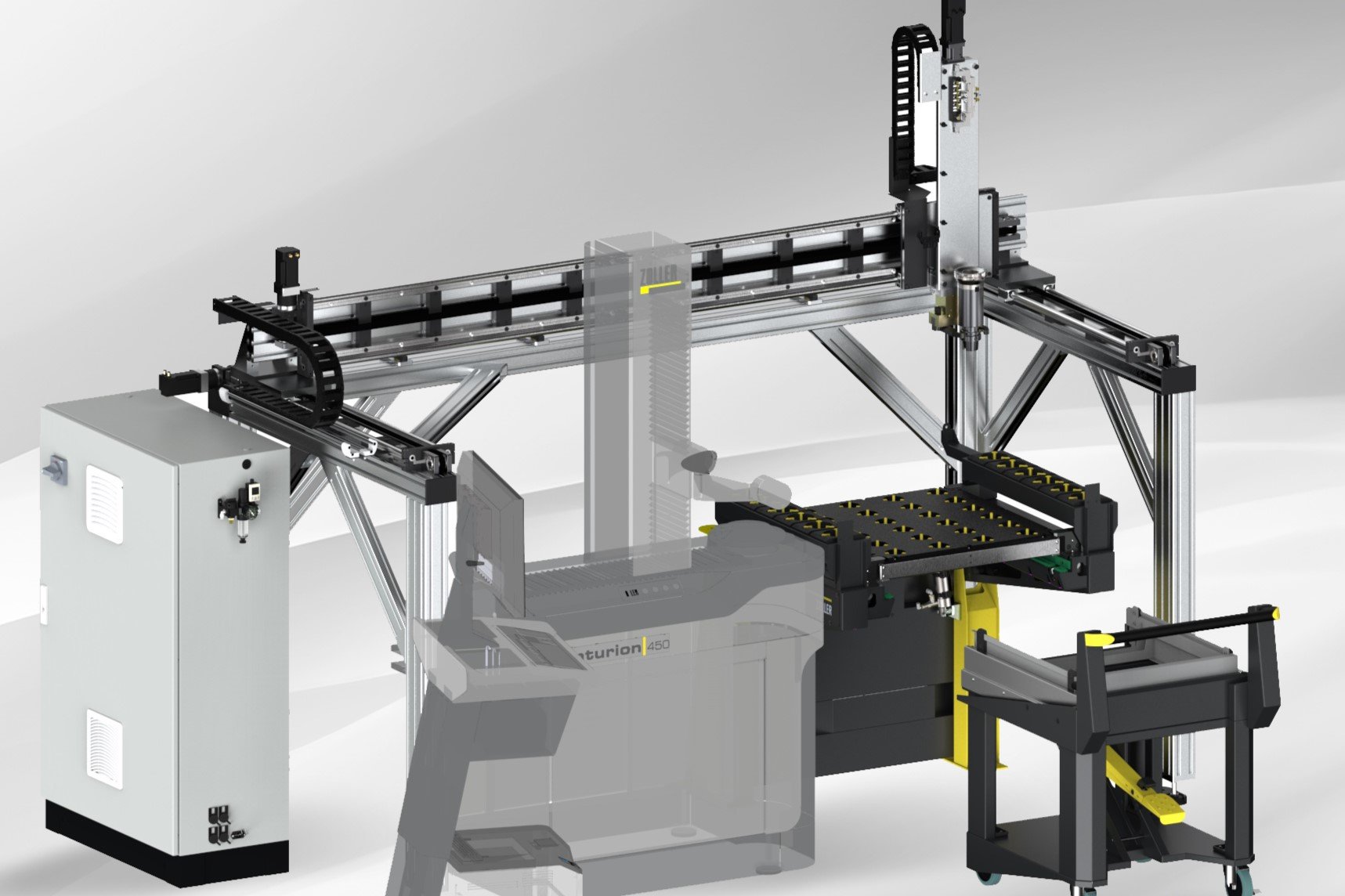

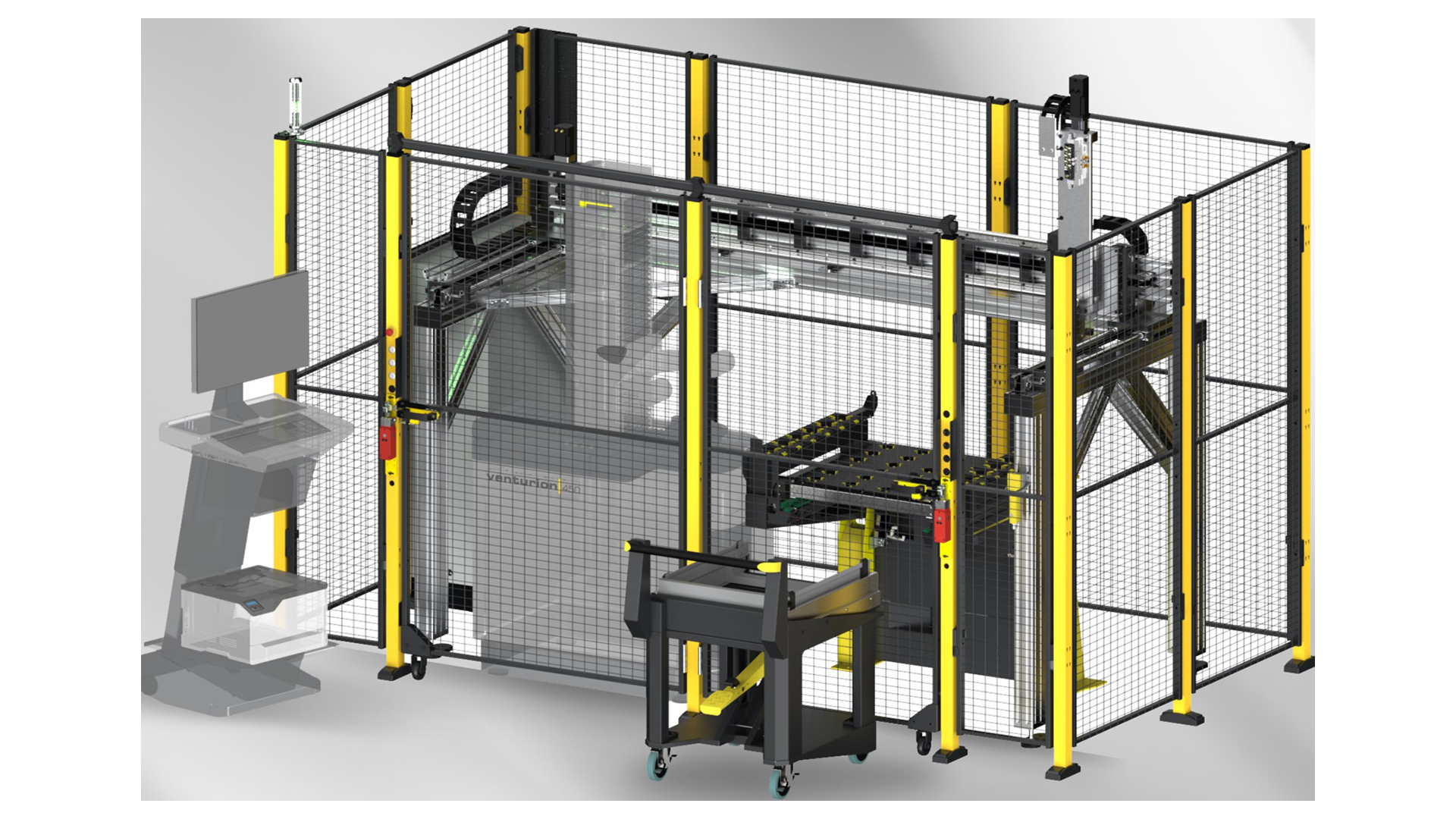

The CoraMeasure LG system is designed to work seamlessly with a Zoller Venturion presetting and measuring machine, consisting of a comprehensive set of components including a linear robot, a pallet system with reject and buffer positions, and a manual transport cart. Tools are first assembled in the pallet system before the linear robot takes over, loading them into the Venturion for precise measurement. Each tool is easily identifiable through the idChip system, with updated data readily accessible in Zoller’s database. The system’s compact design occupies less than 64 square feet of shopfloor space, yet it can accommodate tools weighing up to 22 lbs and with lengths up to 23.6″. It is configurable for HSK-A 100, HSK-A 63, SK40, and SK50 toolholders, with each pallet fitting up to 24 HSK-A 63 and 20 HSK-A 100 tools.

In addition to the CoraMeasure LG, Zoller will display a broad range of its latest technologies. These include the RoboSet 2, an advanced automation solution that automates tool cleaning, inspection, laser marking, and loading, enabling 24/7, lights-out tool measuring and inspection. Also featured will be Zoller’s PowerShrink heat-shrink system, capable of heat-shrinking tools in under 60 seconds while conserving 30% more energy, and the ToolBalancer system, designed to balance toolholders and grinding wheels for smoother machining and extended tool life.

Further enhancing Zoller’s display, the company will showcase updated designs of its smart storage solutions, which interface with Zoller’s tool management software and most major third-party systems. This includes a custom ToolOrganizer model with upgraded electronics and smart compartments, and an updated version of the twister tool dispenser with a revamped push system.

Zoller is also set to introduce ZidCode 4.0 with expanded z.DMI technology, a cutting-edge communication platform that enables secure, real-time tool data transfer between presetting machines and CNC controls, enhancing tool life monitoring and traceability without interrupting machine operations.

Rounding out the display will be Zoller’s torquematic presetting and measuring machine, featuring an ergonomically designed torquing station that allows tools with collet chucks to be set to length, clamped to a predefined torque, and measured fully automatically, all while prioritizing operator safety.

These innovations from Zoller are set to revolutionize shopfloor connectivity and efficiency, providing manufacturers with the tools they need to thrive in an increasingly automated and digitalized production environment. Attendees at IMTS 2024 will have the unique opportunity to experience these advancements firsthand and explore how Zoller’s comprehensive solutions can drive their operations forward.