Tucked away in Kimbolton, Micron Subcon is the kind of machine shop that quietly underpins some of the most demanding engineering projects in the world. Agile by design and uncompromising on quality, the company has built a reputation for delivering precision CNC machining and CNC grinding across a remarkably diverse range of industries.

From automotive and Formula 1 to aerospace and specialist fixturing, Micron Subcon thrives where tolerances are tight, lead times are short, and reliability is non-negotiable. Rather than focusing on a single sector, the business has deliberately positioned itself to support customers wherever precision is critical—adapting processes, materials, and workflows to suit each application.

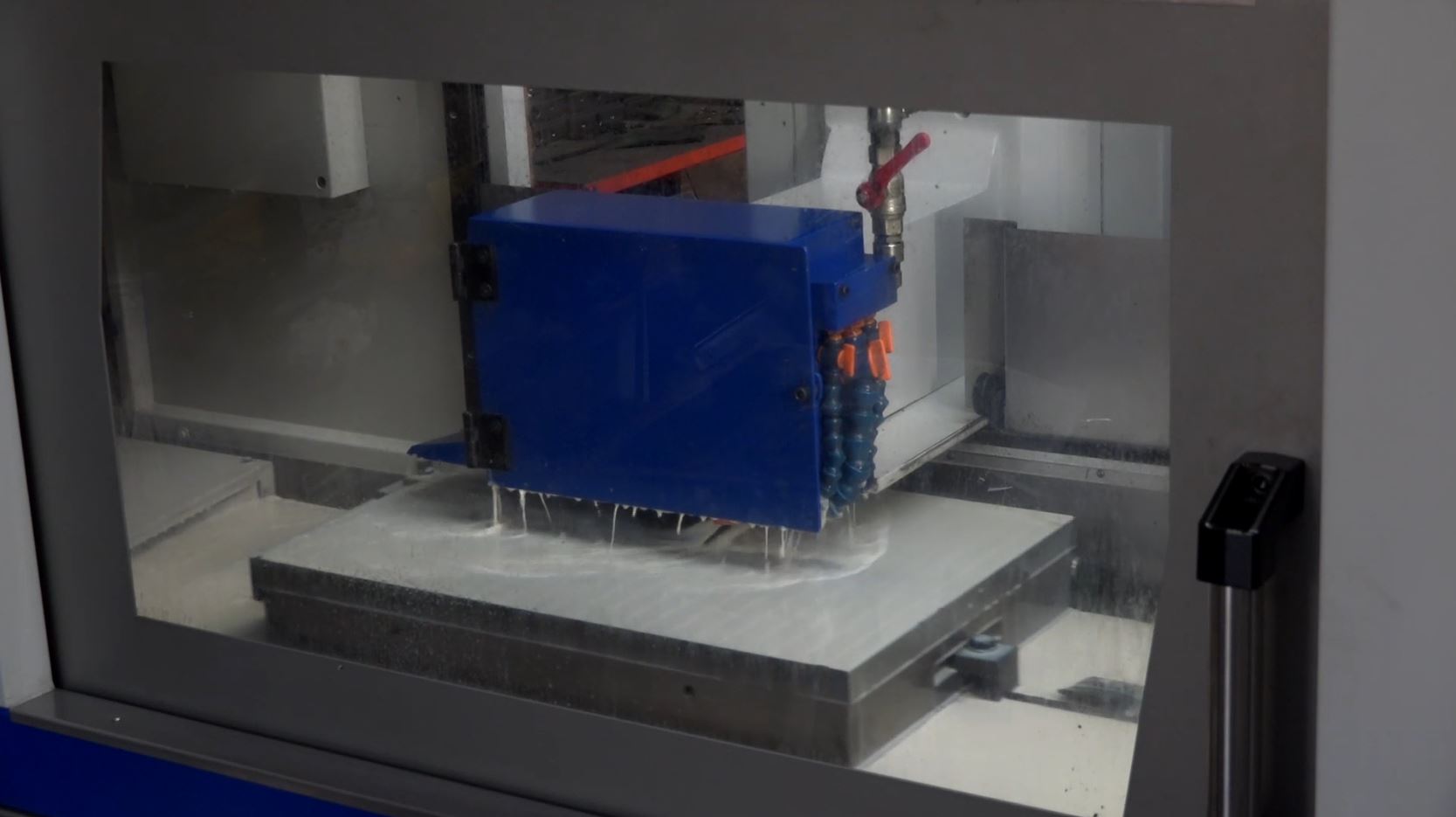

At the heart of Micron Subcon’s capability is a carefully selected machine tool portfolio. High-precision CNC machining is delivered using advanced equipment from Matsuura and Nakamura-Tome, machines renowned globally for rigidity, thermal stability, and repeatability. This investment enables the team to confidently machine complex components with consistent accuracy, whether producing one-off development parts or repeat production runs.

CNC grinding further strengthens the company’s offering, allowing Micron Subcon to control critical dimensions and surface finishes in-house. This capability is particularly valuable for customers in motorsport and aerospace, where performance often depends on micron-level accuracy and flawless surface integrity. By combining machining and grinding under one roof, the business reduces reliance on external suppliers, shortens lead times, and maintains tighter control over quality.

Agility is a defining trait of Micron Subcon’s operation. The team is accustomed to switching seamlessly between industries and component types—one day supporting a fast-paced motorsport programme, the next producing precision parts for aerospace or bespoke fixtures for manufacturing environments. This flexibility is backed by strong engineering knowledge, allowing the company to engage early with customers, offer practical input on manufacturability, and help refine designs for optimal performance and cost-effectiveness.

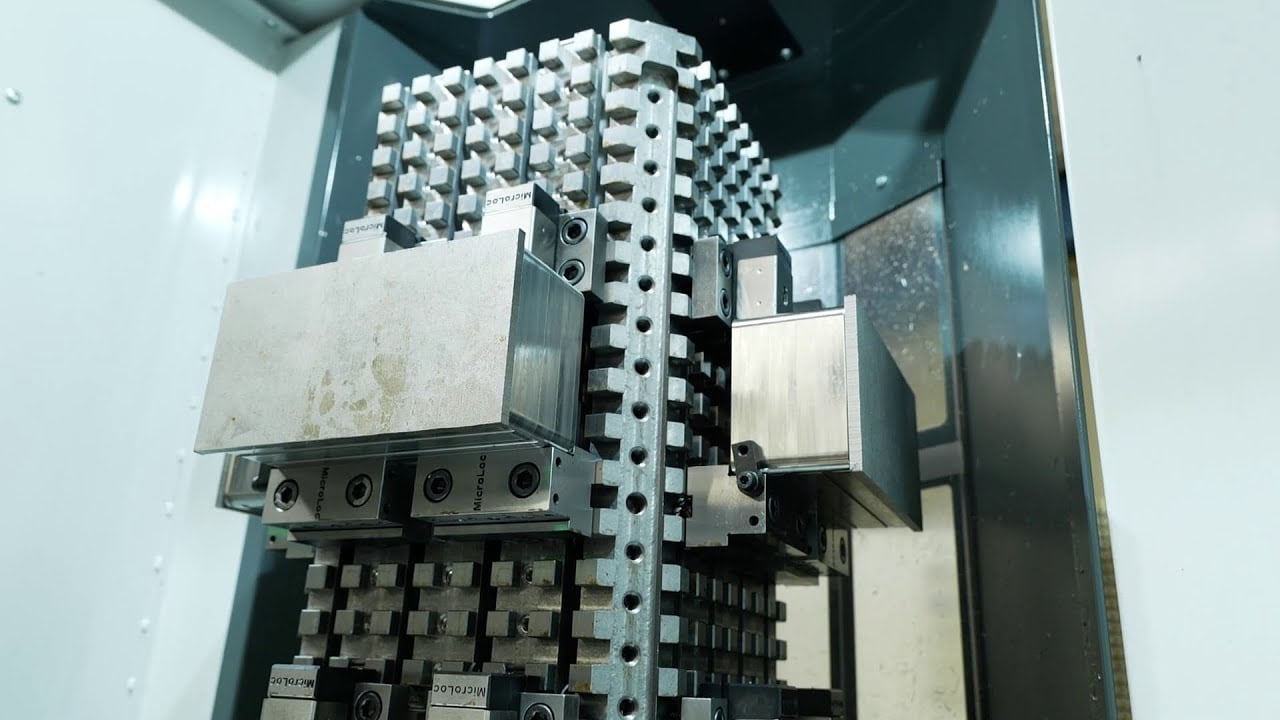

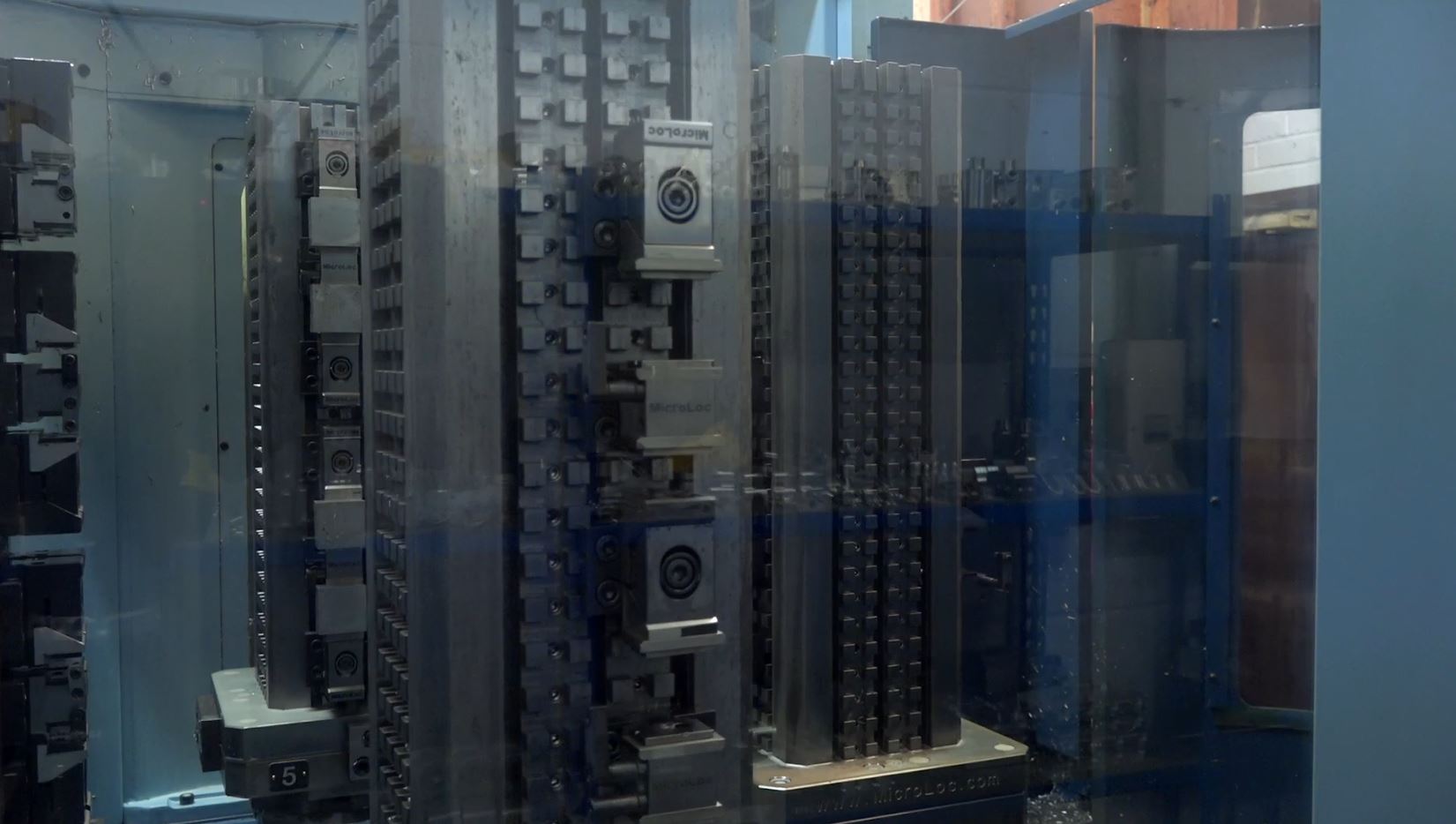

Fixturing is another area where Micron Subcon excels. Precision fixtures play a crucial role in ensuring repeatability and efficiency across many manufacturing processes, and the company’s experience in machining and grinding gives it a deep understanding of what is required to achieve stable, accurate workholding solutions. These fixtures often become an integral part of customers’ production strategies, supporting long-term quality and throughput improvements.

While technology is central to the business, Micron Subcon’s success is equally rooted in its people and approach. A strong emphasis on quality, communication, and responsiveness ensures that customers receive not just precision parts, but a dependable manufacturing partner. Whether responding to urgent requirements or supporting long-term programmes, the company’s mindset remains the same: deliver accuracy, consistency, and confidence.

In an era where manufacturing must be both highly specialised and highly adaptable, Micron Subcon stands out as a machine shop that bridges that gap. By combining advanced CNC machining and grinding capabilities with an agile, industry-spanning approach, the Kimbolton-based specialist continues to play a quiet but vital role in some of the most demanding engineering sectors—proving that true precision knows no boundaries.