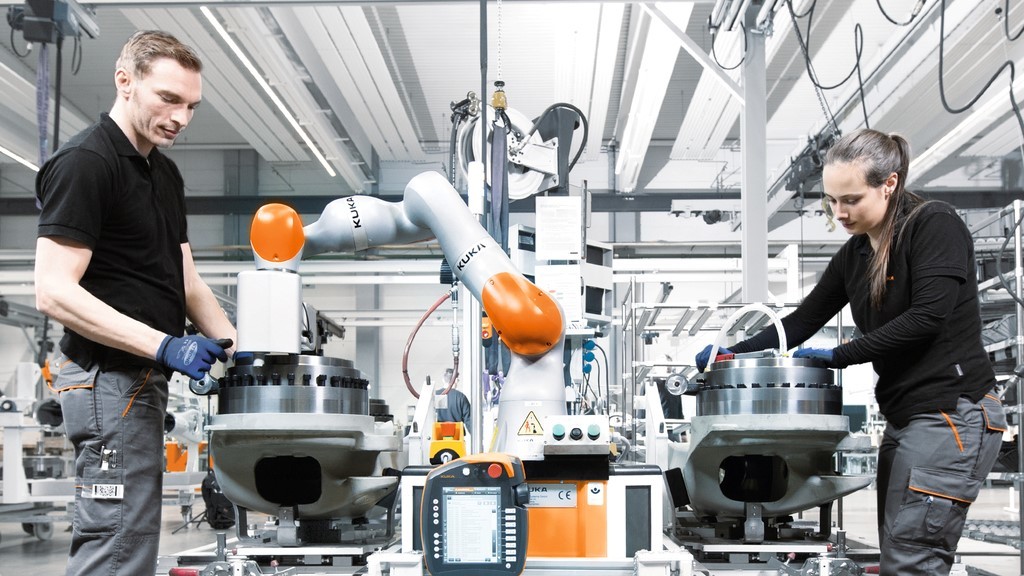

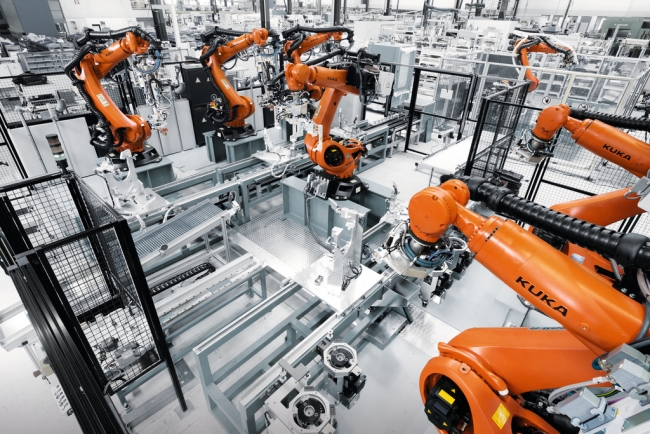

Robotics play an integral role along production lines in medical device, biologics and pharmaceutical manufacturing.

From parts sorting, product assembly and light machine-tending, to quality inspection and packaging. Environmental and product sampling, to seed laboratory automation, kitting logistics, UV-C disinfection and cleaning processes.

Why the Life Sciences sector embraces robotics:

- Cleanroom space is costly; robotics reduces overall footprint.

- Labour content is traditionally high; reduced resource pools and rising costs. Robotics reduce inefficiencies and costs.

- Robotic technologies provide the basis for more applications, versus legacy technologies; cobots, vision, mobile robotics and haptic control all support this growing sector.

Stringent regulations mean medical device manufacturers must reproduce identical products, under rigorous cleanroom conditions, within reduced timeframes. Keeping pace with innovation, manufacturing agility and adaptability, aligned with changing product iterations, is essential.

- Modular robotics systems are easy to update, and efficient in operation.

- Automated quality inspection systems enable 100% parts inspection.

- Machine vision technology can verify serialisation numbers, satisfying compliance and traceability regulations.

- Robotic cleanroom processes eliminate human contamination risks; processes involving high toxicity ingredients. Operator safety is paramount.

Personalised medicines and medical devices are prohibitively expensive. Automation reduces production costs delivering critical, life enhancing treatments as widely as possible. Consider personalised cell and gene therapy, implants and prosthetics – high variety, small batch production requiring highly flexible, robotic manufacturing processes.

The benefits increased manufacturing efficiencies afford through robotic automation include:

- Productivity

- Quality

- Repeatability

- Waste reduction

- Traceability

- H&S

- Cost savings/ROI

The clear shift within Life-Sciences is towards robotics. Traditional, manual operations are being evaluated for automation, and greenfield plant designs incorporate automation as standard.

- Historically medical device design focused upon the ‘use case’ with little consideration of successfully manufacturing at scale; engineers now engage at concept through launch, ensuring products are designed for manufacture and automation.

- Robots are more widely accepted; operatives are increasingly receptive to the benefits delivered automated manufacturing.

Pharmaceutical and biologics companies are investing in robotics, many with dedicated teams further exploring automation opportunities. Those above-mentioned benefits mean robots are increasingly being incorporated into applications as technologies evolve and demand increases, such as for new medicines and treatments. Notably those arising from COVID-19. Robotic automation is integral to sustaining the growth and evolution of Life Sciences – an important sector for economic growth, which in 2019 generated a turnover in excess of €80bn.