We combine our highly skilled operators working across two shifts and our broad range of machinery to provide a complete steel and aluminum folding, forming and rolling service. Materials process include sheet, plate tube, angle and box section materials in stainless steel, mild steel and aluminum.

With Contracts Engineering, you can be sure that our team will provide a fabrication service that will meet your requirements.

ABOUT OUR METAL BENDING, FOLDING AND FORMING SERVICES

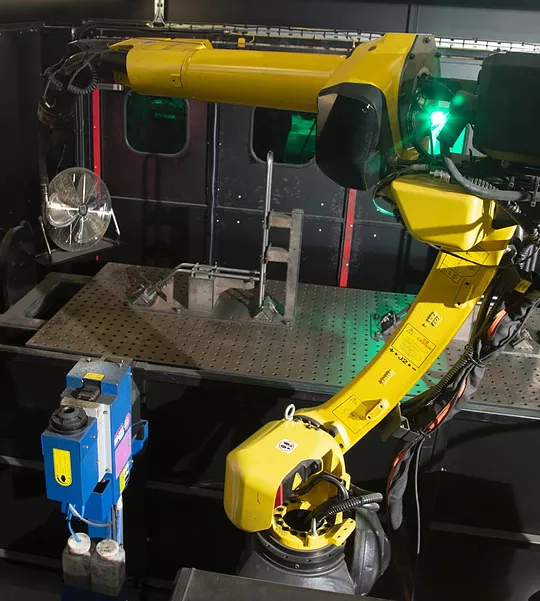

We have a highly skilled team of machine operators managing this work centre, which includes press brakes, forming and section/plate rolling machines, consisting of:

-

Bystronic Xpert 3 metre x 100 ton 8 axis CNC press brake

-

Edward Pearson 3 metre x 100 ton 6 axis CNC press brake

-

2qty CNC 3-Pin Section Rolling Machines; including a Prosaw AKYAPAK ASM 140-12/5 Plate Rolling Machine capable of rolling 10mm carbon steel and 6mm stainless steel up to 900mm wide

-

Baileigh R-H85 section rolling machine capable of rolling a range of square and round hollow sections, as well as angles.

-

Ercolina CNC Tube Roller with a large library of tooling and dies

We boast of a highly extensive tool library in addition to our folding and forming machines. This includes both air-bend and bottoming dies which allow us to create complex bends such as corrugations, roll beads, crush folds and the standard 90° fold.

Pressbrakes, Rolling Machines & Metal Forming Processes

Our press brakes are capable of folding 3mm mild steel at a 90° angle across a 3-metre length. With the Bystronic Xpert you can trust that with our metal bending services, the machine will not produce angle errors and will produce a perfect bend every time. Both machines in our factory are fully CNC, which additionally gives us the ability to check angles down to 0.5° accuracy. We have extremely high capabilities when it comes to metal forming processes.

Our rolling machines give us the flexibility to roll a variety of thicknesses and diameters to meet your specifications. We can roll tubes up to 102mm O/D with a 3mm wall, box section that is 70x70mm with a 4mm wall and an 86x86x6mm angle. This precision is achieved by a mix of top-grade equipment and a well trained, skilled team.

WHY CHOOSE US FOR YOUR FORMING AND METAL FOLDING SERVICES?

-

Lead Times & On-Time Delivery in Full. We operate by a daily two-shift system and cross-train our staff to help us minimize our lead times and offer flexibility. We have developed a leading production planning ERP system that uses Artificial Intelligence to plan production and manage our customers’ requirements. We track On-Time-In-Full deliveries as one of our two Core KPIs. Our achieving industry leaving KPIs not only keep our customers happy, then feed into our profit share system.

-

Quality Assurance. Avoiding external quality issues is our other Core KPI. We have built a Quality Management System that is engrained throughout the Company and everyone on the team plays a role in hitting our target. We hold an ISO 9001:2015 accreditation with the British Standards Institute and have developed our own Standard Operating Procedures (SOPs) for every area in the company to ensure our quality standards. And when we meet or exceed our customers’ expectations, we achieve part of our bi-annual profit share.

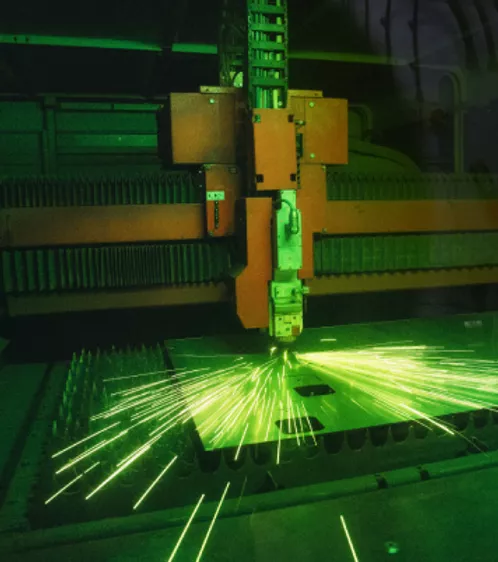

To hear more about our metal folding and metal forming services, or to have your questions answered by one of our dedicated engineers, get in touch. Alternatively, if you would like to read more about our other metal fabrication services, take a look here: Welding Services, Punch, Laser Cutting Services.