As Arnold Wragg is a proud AS9100 accredited company in order to maintain our high quality standards all incoming materials are subject to a full metallurgical and property testing plan before being accepted from the mill or source.

In addition to these exacting requirements full inspection and verification is continuous during and on completion of manufacture, ensuring that our customers receive products of the highest integrity and quality.

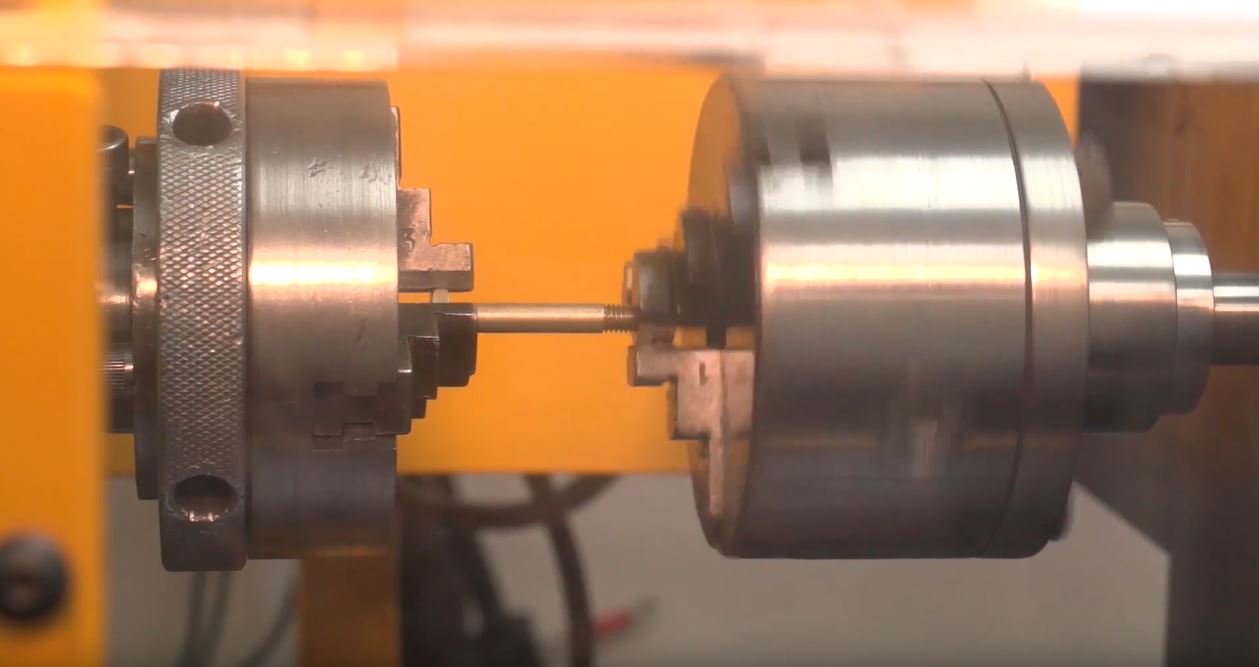

Arnold Wragg has a wide range of inspection and testing facilities including dimensional control, torque, hardness and metallurgical. Full documentation COC packs including First Article Inspection Reporting (FAIR)

Inspection process complying with AS9100 standards and demands and include

• Faro arm inspection reporting

• Mechanical testing, certification of conformity COC

• Stage inspection / verification

• Final inspection

• Mill certification

• Metallurgy report

• Independent witnessing

• First article inspection reporting (FAIR)