Inside Weiss Spindle Services: precision engineering down to the micron

This brand-new, fully temperature-controlled facility in Cheadle is setting a new benchmark for spindle repair in the UK.

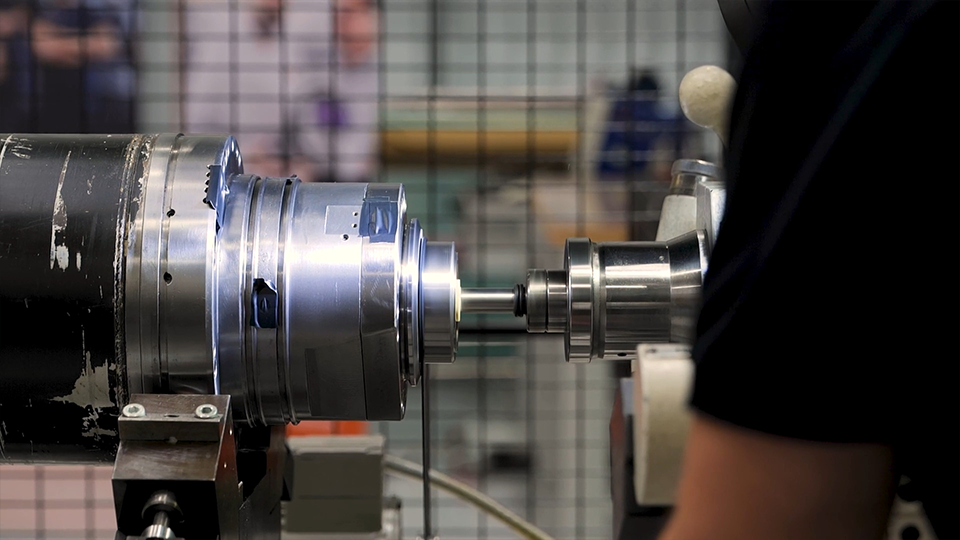

From detailed incoming inspections and full photographic reports to in-house grinding of assembled spindles, every repair is engineered for micron-level accuracy, extended spindle life, and reduced machine downtime. Backed by global expertise from their German HQ and a rigorous multi-stage test process, Weiss delivers repairs comparable to a new spindle – with modifications tailored to each customer’s process.

Join MTDCNC’s Lyndsey Vickers and Christian Kess of Weiss Spindle Services for a behind-the-scenes tour showing how precision, process control, and transparency are raising the bar for spindle repair in the UK.