Spinner Showcases Next-Gen Automation at 30th In-House Exhibition in Sauerlach

Vertical integration, compact automation, and customer proximity — the foundations of Spinner’s success.

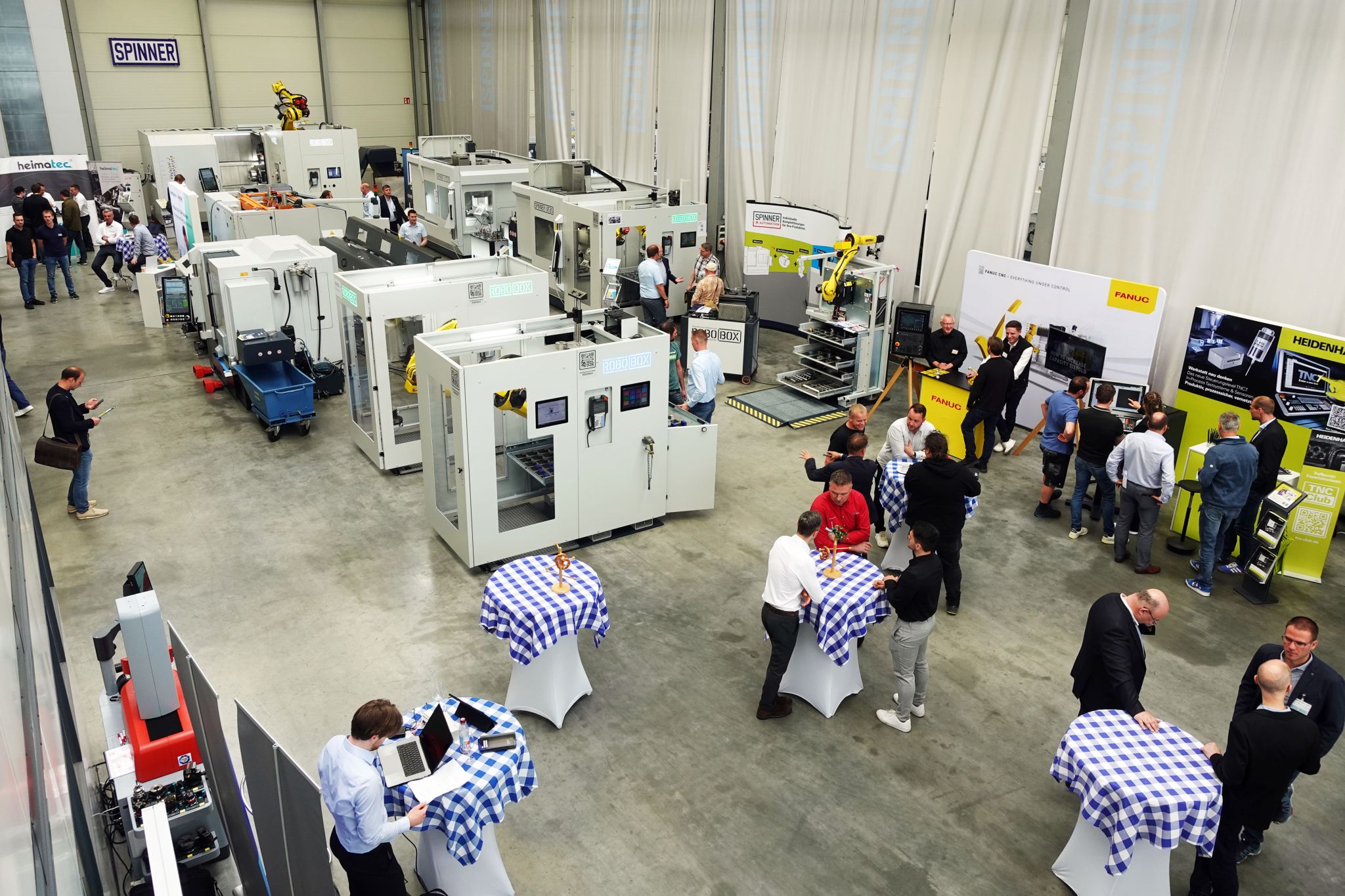

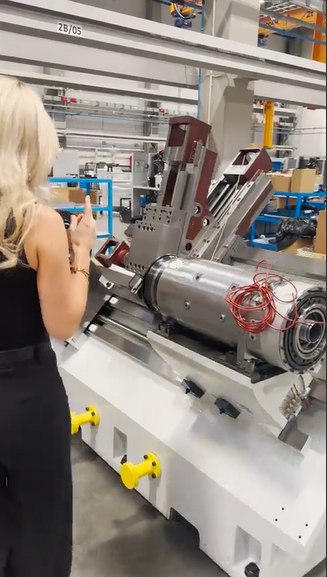

At their headquarters in Sauerlach, south of Munich, Spinner recently held their 30th in-house exhibition from 21–23 May, welcoming customers and partners to explore the latest generation of high-precision lathes, milling machines, and automation solutions.

But this wasn’t just a product showcase — it was a demonstration of how far integrated automation has come. As CEO Axel Spinner explains, automation is now central to the Spinner machine concept:

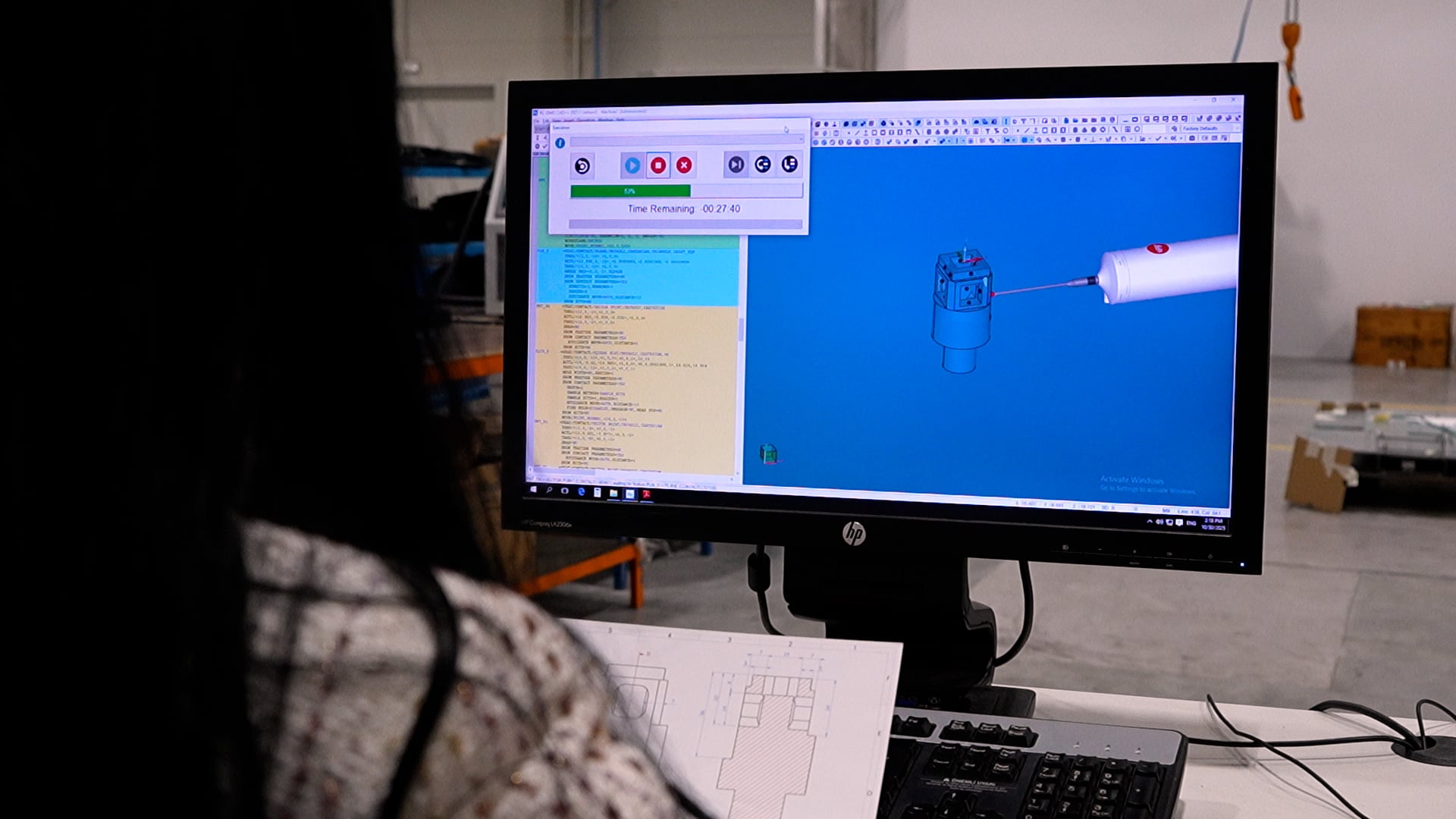

“Our subsidiary, SPINNER Automation GmbH, has developed automation solutions that are perfectly matched to our machines. Perfect means: fully integrating machining, measuring, deburring — and doing so in a compact footprint.”

This compact integration is a key factor for many buyers — especially SMEs, automotive suppliers, and tech manufacturers who must balance space, cost, and performance.

Why customers choose Spinner:

- ✅ High vertical integration for quality and flexibility

- ✅ Automation engineered in-house for seamless integration

- ✅ Compact machines with precision in the micron range

- ✅ Lean structures and direct access to leadership

- ✅ Outstanding price-performance ratio

“You can even speak directly with the managing director if needed,” says Axel Spinner, underlining the personal, transparent support Spinner is known for.

With automation, machine technology, and service all under one roof, Spinner continues to offer a unique value proposition: future-ready production systems, built with customer proximity in mind.