Open Mind Showcases hyperMILL and Hummingbird MES at EMO Hannover 2025

At EMO Hannover 2025, Open Mind will demonstrate how its advanced CAD/CAM technologies and integrated manufacturing solutions can transform modern production environments. The company will showcase the latest version of its renowned hyperMILL® CAD/CAM suite together with the Hummingbird Manufacturing Execution System (MES). Visitors can find Open Mind at Stand A41 in Hall 6 during the exhibition, which takes place from 22 to 26 September 2025.

The spotlight of the stand will be on the seamless interaction between CAD/CAM programming, MES integration, and real-world machining. Through a mix of live machining and interactive demonstrations, Open Mind aims to highlight how digital connectivity and efficient workflows can drive productivity across the shop floor.

hyperMILL® CAD/CAM Demonstrations

Four dedicated workstations will give visitors the opportunity to explore the full potential of the hyperMILL® suite. Expert-led sessions will demonstrate strategies and functions for mill-turning, turn-milling, and turning operations. Attendees will be able to see how hyperMILL® supports complex geometries, optimises toolpaths, and increases efficiency while maintaining high levels of accuracy. These sessions are designed to provide both an overview of the software’s core strengths and in-depth insight into specific manufacturing challenges.

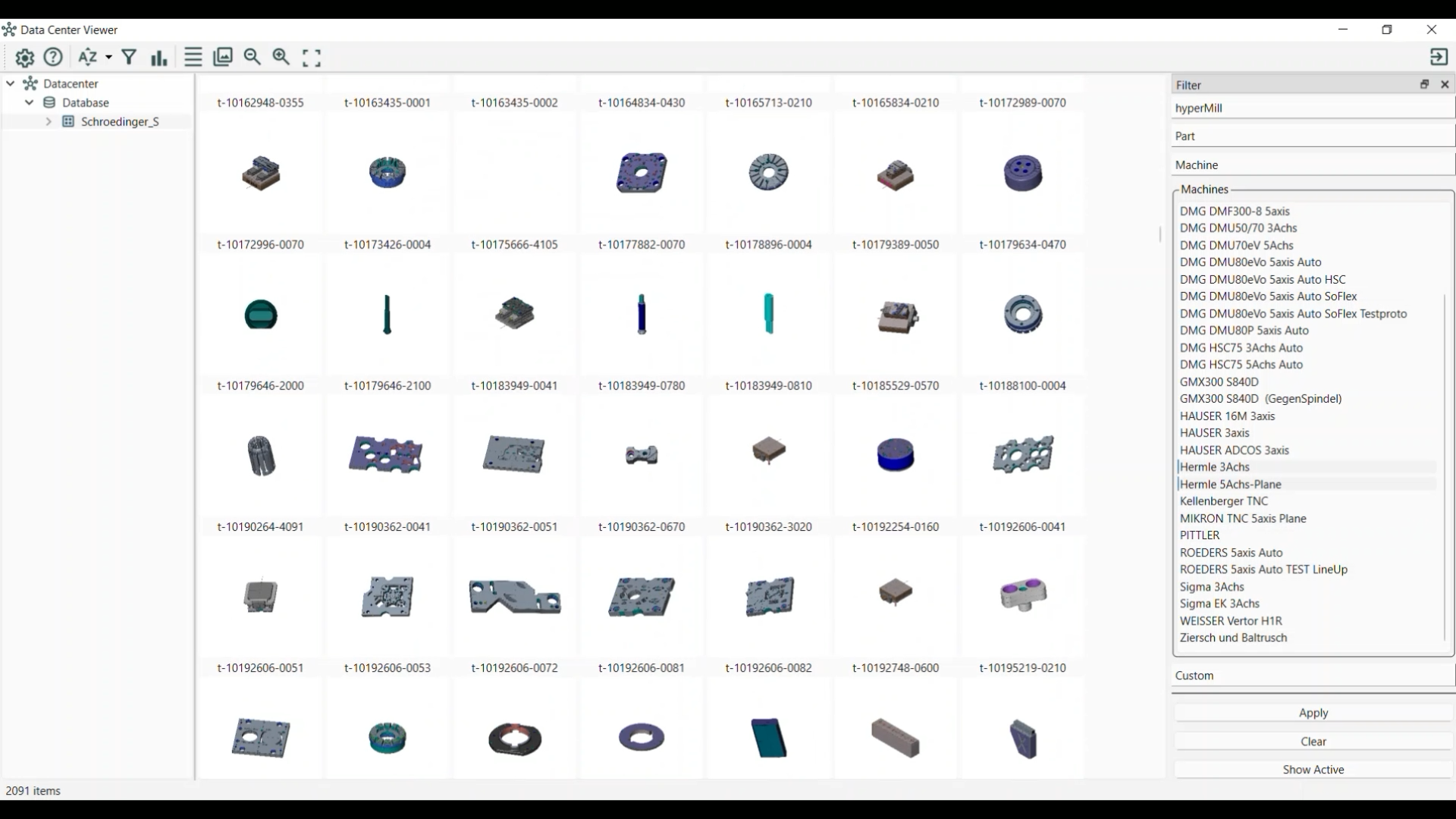

Hummingbird MES for Connected Manufacturing

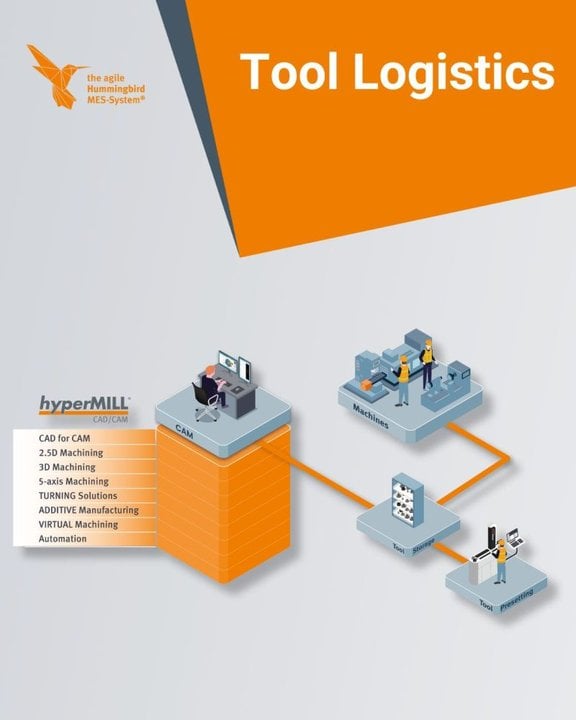

Alongside hyperMILL®, Open Mind will highlight the Hummingbird MES, a solution that ensures digital continuity between CAM programming and CNC execution. The system is built around four essential pillars:

- Synchronised planning and control to streamline operations.

- Machine data acquisition for real-time monitoring and optimisation.

- Tool management to ensure consistent performance and availability.

- CAM/CNC integration that closes the loop between programming and production.

By linking these components, the Hummingbird MES provides a practical pathway to connected manufacturing, offering manufacturers a reliable tool for greater transparency, control, and efficiency.

Live Machining on the Mazak Integrex

A highlight of the stand will be a Mazak Integrex i-100H S turn/mill centre running live demonstrations. Visitors will witness the machining of an aerospace workpiece, showcasing the power of five-axis machining and hyperMILL® turning solutions in action. This real-time demonstration underlines how Open Mind’s software can unlock the full performance of advanced machine tools, ensuring precision and productivity in demanding industries such as aerospace.

With the combination of hyperMILL® and Hummingbird MES, Open Mind is set to show EMO Hannover visitors how digital integration and smart machining strategies can pave the way to future-ready manufacturing.