TRUMPF Introduces AI-Powered ‘Cutting Assistant’ to Optimise Laser-Cut Quality and Boost Productivity

At its recent INTECH in-house trade fair, TRUMPF unveiled its latest innovation in smart manufacturing: the Cutting Assistant, an artificial intelligence (AI)-driven application designed to significantly enhance the quality of laser-cut edges and reduce the need for manual parameter adjustments.

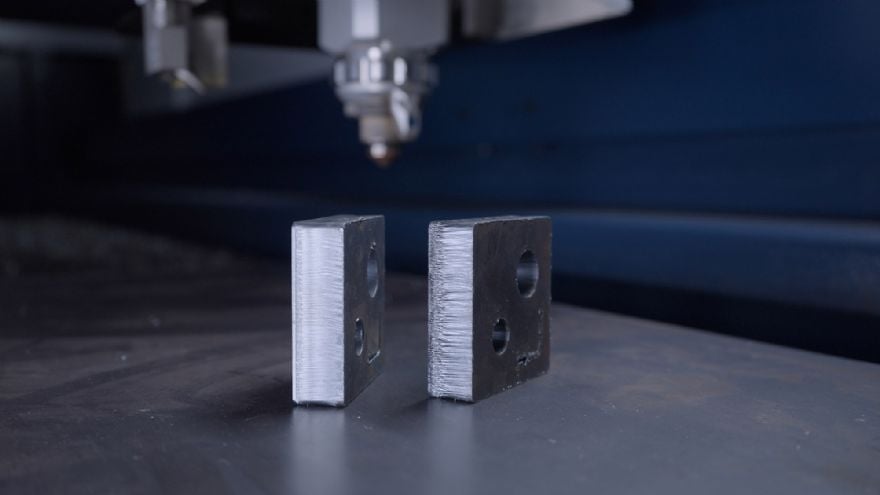

The Cutting Assistant enables production staff to evaluate and optimise their laser cutting processes using a hand scanner and a simple workflow. By capturing an image of a part’s cut edge, the application automatically assesses quality indicators, such as burr formation, and provides suggestions for optimised machine parameters. These improved settings are then seamlessly transferred to the laser cutting system, enabling users to rerun the process without the need for manual adjustments.

“With the Cutting Assistant, TRUMPF is once again demonstrating its role as a pioneer in the industrial application of AI,” said Louisa Peters, Product Manager at TRUMPF. “This tool not only supports manufacturers facing a shortage of skilled workers, but also helps them reduce time, costs, and rework—delivering a real competitive edge in production.”

The Cutting Assistant is currently available for all TruLaser series machines with a power output of 6kW or higher. For existing customers, the tool is accessible via a simple software download, allowing many to start using the AI solution immediately without needing new hardware or complex installations.

Laser cutting operators often face challenges in identifying the correct parameters for various material types, particularly those not optimised for laser cutting. Traditionally, workers had to adjust settings one by one—a process demanding both time and expertise. The Cutting Assistant automates and simplifies this step, making precision cutting more accessible to less experienced operators.

The AI algorithm behind the Cutting Assistant was trained using thousands of real-world cutting operations carried out by TRUMPF engineers. As more users adopt the system, anonymised application data will continue to improve the model’s performance, making it faster, smarter, and more reliable over time. TRUMPF emphasises that user expertise and data remain secure, with no risk of unauthorised sharing.

“We’re committed to innovation that benefits manufacturers of all sizes, and data security is a top priority,” Peters added. “Our customers will continue to receive regular updates that enhance functionality and ensure peak performance.”