DN Solutions Launches Metal 3D Printing Line at DIMF 2025, Signaling New Era in Manufacturing Innovation

DN Solutions, Korea’s leading machine tool manufacturer and the world’s third largest, has officially entered the metal additive manufacturing market with the launch of its new DLX series of metal 3D printers. The announcement was made during DIMF 2025 (DN Solutions International Machine Tool Fair), held April 2–5 across the company’s Busan and Changwon facilities.

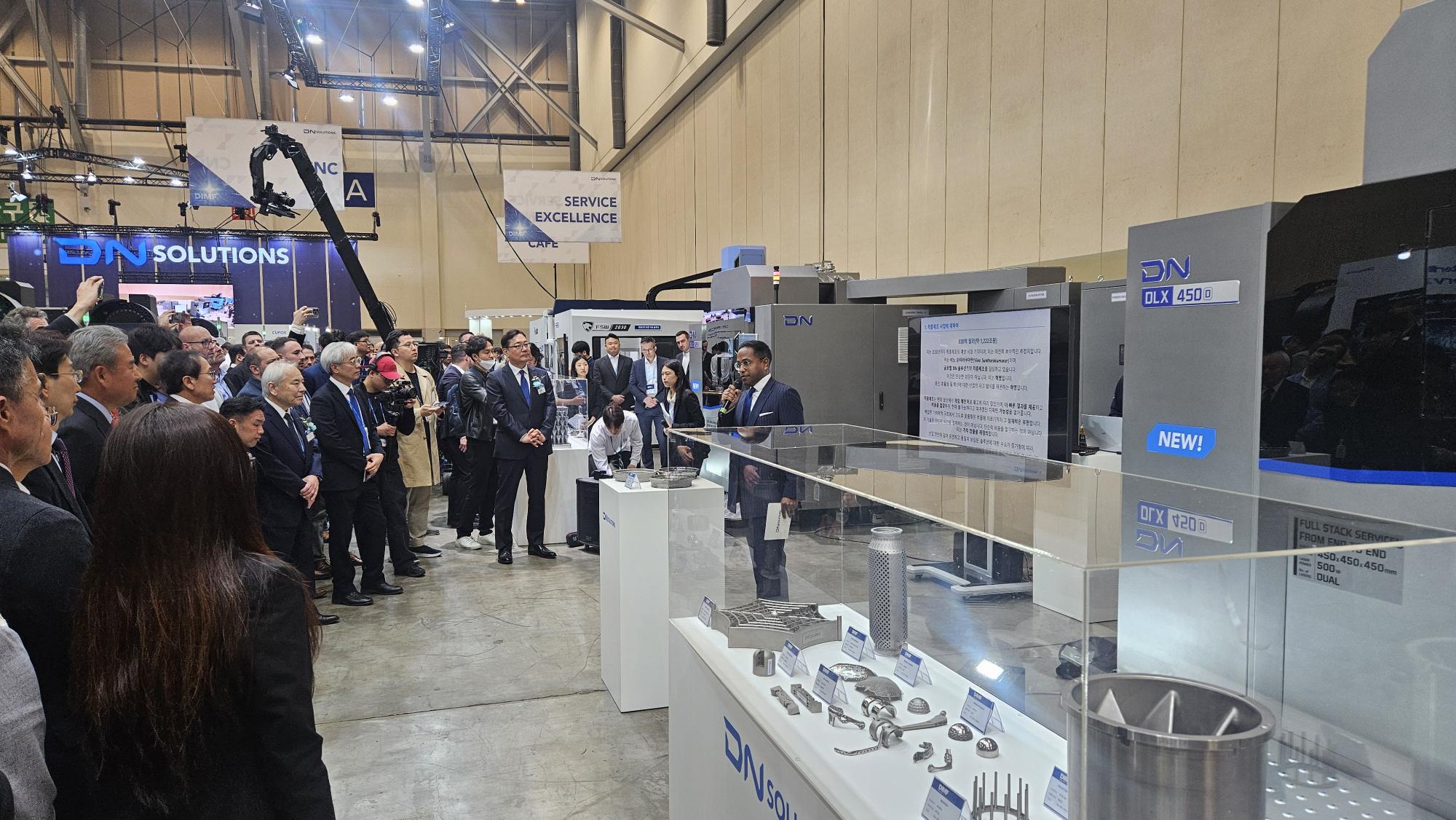

Now in its 15th edition, DIMF welcomed more than 5,000 visitors, including 1,000 international partners and customers. Under the theme “Automation Solutions Platform for All Machining Processes,” the event showcased over 50 advanced machining centers, automation solutions, and for the first time, cutting-edge additive manufacturing (AM) technologies.

A Major Leap Into Additive Manufacturing

Headlining the event was the unveiling of the DLX series, DN Solutions’ first industrial-grade Laser Powder Bed Fusion (LPBF) 3D printers. The flagship DLX 450—capable of producing complex metal parts up to 450 × 450 × 450 mm—was demonstrated live, processing aerospace and medical-grade materials such as titanium, Inconel, and aluminum alloys. The system supports one to four fiber lasers (500W–1kW), build speeds up to 20 cm³/hour, and layer thicknesses between 30–90 μm.

DN Solutions’ proprietary AM software suite offers a complete digital workflow, from identifying AM-suitable parts and cost estimation, to deformation simulation, process map development, and quality optimization.

Performance Validated and Global Support Growing

To showcase real-world impact, DN Solutions redesigned a spindle cylinder front cap using Design for Additive Manufacturing (DfAM) principles, resulting in a 20% performance improvement and simplified part assembly.

As part of its additive strategy, the company also announced the opening of its Additive Manufacturing Solution Center (ASC) in Germany, with additional hubs planned for South Korea and the United States. These centers will provide prototyping, process optimization, and full production support for global customers.

“This marks a major step forward,” said DN Solutions CEO Wonjong Kim. “As we continue to support over 290,000 machine tools worldwide, our expansion into additive manufacturing reinforces our commitment to delivering future-ready, integrated manufacturing solutions.”

With this move, DN Solutions positions itself at the forefront of a growing global shift toward hybrid manufacturing that fuses traditional machining with advanced AM technologies.