Hexagon to Show Optimised Workshop Efficiency at Global Industrie

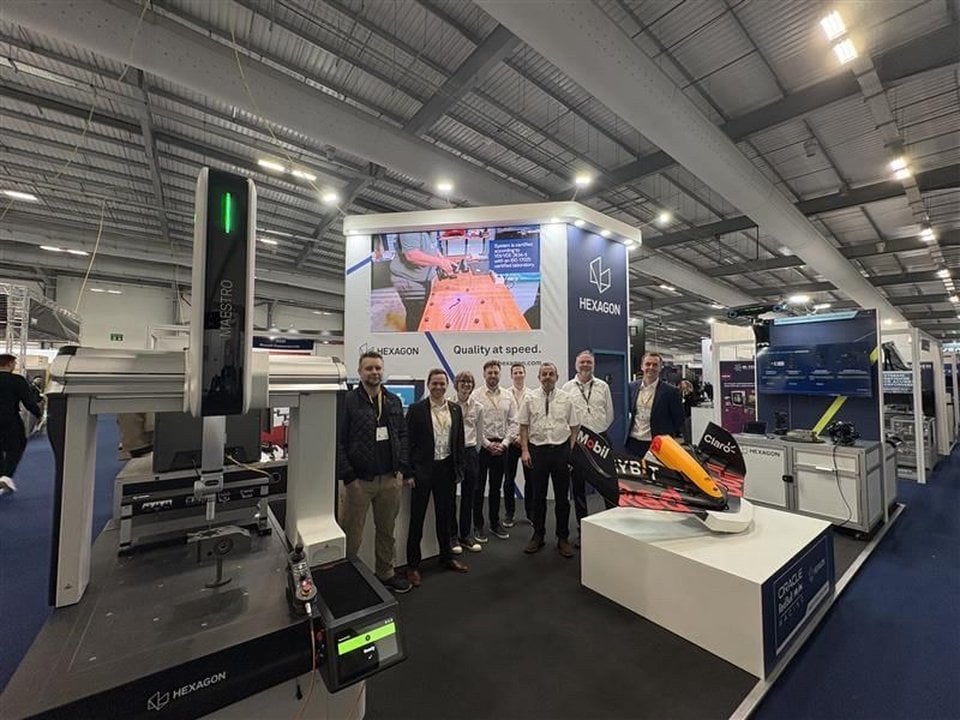

Visitors to the Hexagon booth at the rescheduled Global Industrie exhibition in June will see how workshop efficiency can be optimised by combining CNC machine tools with their digital twins.

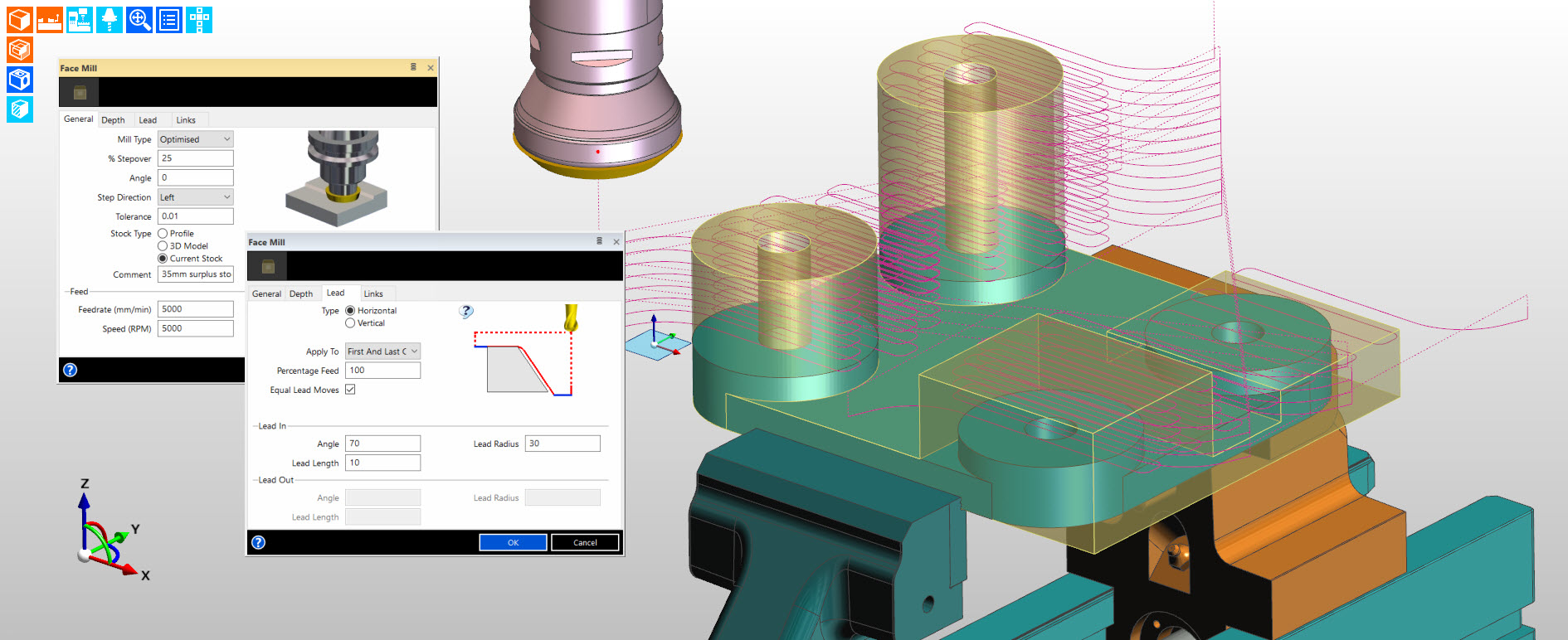

While the four modules comprising the complete NCSIMUL solution are being demonstrated, visitors will be able to test NCSIMUL 4CAM for themselves through Virtual Reality goggles. NCSIMUL 4CAM automatically converts CAM and NC programs to different machines. This gives the ability to switch quickly between different machines, kinematics and controls, and better utilise the shop floor…while also commissioning new machine tools faster by using existing NC programs.

The other modules are NCSIMUL Machine for NC simulation and ISO code verification, NCSIMUL Optitool for powerful optimisation of machining times, and NCSIMUL Monitor for real-time monitoring of machine states. Overall, NCSIMUL is a major software brick in the digital continuity process for ensuring that a part is compliant and accurate the first time.

NCSIMUL is one of Hexagon’s software solutions, giving users total control over their workshop and the machining process by enabling flexible and collision-free machining. This is achieved, in particular, through creating virtual twins of real machines, verification of ISO programs, machining simulation for precise toolpath optimisation, program management and transfer, and monitoring machine states in real time.

To help manufacturers with their Industry 4.0 philosophy, Hexagon’s CAD/CAM, simulation and MES production solutions integrate seamlessly with each other to exploit data, improving manufacturing efficiency and quality, while reducing costs.

NCSIMUL, EDGECAM, VISI, WORKNC, WORKPLAN, WORKXPLORE – International Exhibition of Industry in France, Global Industrie Paris Nord Villepinte, from June 23 to 26, 2020.