6000 Aerospace Brake Clips a Week – How Westley Engineering Achieved 24/7 Lights-Out Production

At Westley Engineering Ltd, precision and productivity go hand in hand. The Birmingham-based manufacturer is currently producing an incredible 6,000 aerospace brake clips every week—a critical component for the aviation industry. And none of it would be possible without the partnership and support of Whitehouse Machine Tools.

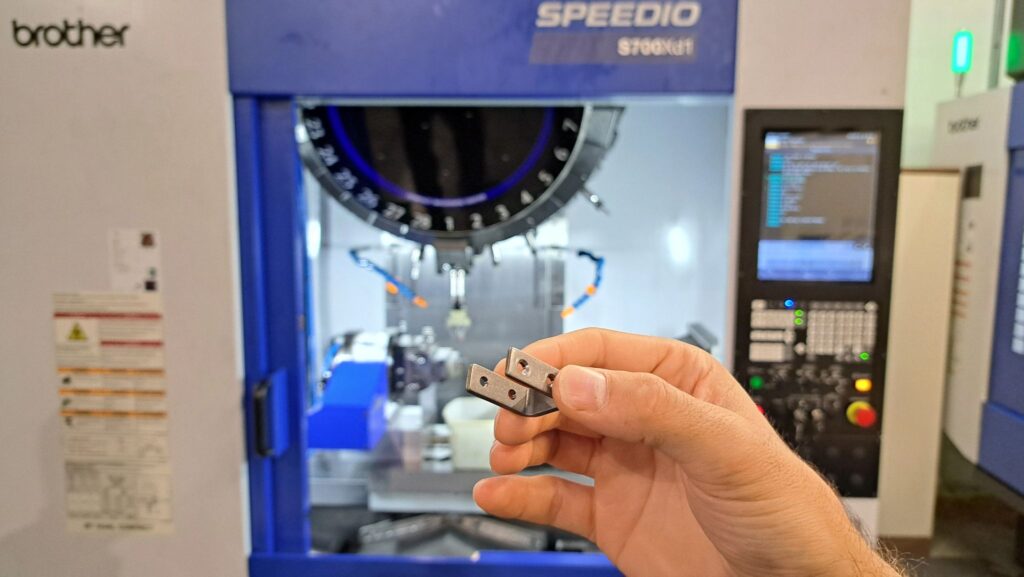

These brake clips were once fully manufactured in Westley’s press shop. However, as customer requirements tightened—especially around tolerances and repeatability—Westley turned to CNC machining to maintain quality at scale. That’s where two Brother S700Xd1 machining centres came into play.

Supplied by Whitehouse Machine Tools, these high-speed Brother machines offered the ideal blend of precision, speed, and compact footprint. But it wasn’t just about the machines. To make the process truly efficient, Whitehouse machine tools designed and built bespoke automation ensuring maximum output.

The result? A lights-out manufacturing solution that now runs 24 hours a day, 7 days a week, with minimal operator intervention. It’s a powerful example of how traditional manufacturing companies are embracing smart automation to boost productivity without sacrificing quality.

A big thank you to Paul Proctor and John Harland of Westley Engineering for the behind-the-scenes tour.

This collaboration between supplier and manufacturer is a shining example of how UK engineering continues to lead the way in high-spec, high-volume aerospace component production.

Video coming soon…