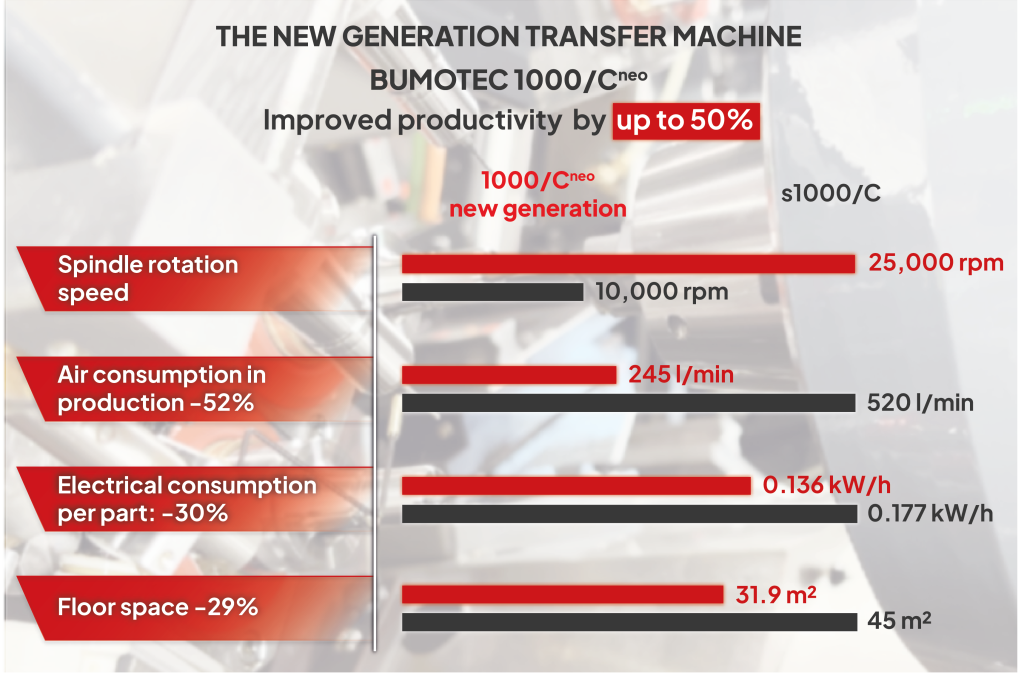

The new Bumotec 1000/Cneo horizontal transfer centre was developed on the basis of feedback from industry to optimise every step of the process. With shorter cycle times, lower energy consumption and easier handling, the machine has 32 motor spindles running at 25,000rpm and a new touchscreen interface. This new Bumotec machine enables manufacturers to produce more while keeping energy costs under control.

The developers of the new Bumotec 1000/Cneo transfer centre did not start with a blank sheet of paper. They built on the practical experience gained from the previous model. “We wanted to know what factors were limiting the customer on their Bumotec s1000/C and what would allow them to increase their production speed,” explains Sylvain Bapst, who is responsible for the development and design of the machines at Bumotec. “We first drew up a specification sheet and then developed a new machine on this basis.”

The first improvement was the interaction between man and machine. A human-machine interface (HMI) from FANUC was chosen. In combination with the 24-inch touchscreen, this allows Bumotec to display more information for the operator. By integrating the WattPilote graphics application, the operator can continue to operate their machine while monitoring the consumption of the spindles on the same screen. The operator can even add virtual buttons, such as a button for selecting the stations or shortcuts for the most frequently used M-codes.

“We have thoroughly revised our HMI so that the operator can control their machine ergonomically and intuitively,” assures Cédric Berger, Head of the Software Department. And he emphasises: “Our aim for our HMI was to make it easier to train new colleagues on a complex machine with 32 spindles and nine machining stations.” Here, too, the company listened carefully to what customers needed: “In view of the shortage of skilled labour, companies often employ people who were not trained as precision engineers in machining technology and who previously worked in other professions. For this reason, it is all the more important that the HMI is designed to be extremely user-friendly. That’s why we put so much effort into its development.”

Bumotec’s software department has also been working on an OPC UA server on which all the machine information can be consolidated. “We have gone even. Instead of using FANUC’s OPC UA server, we have developed our own server to give users more flexibility so that they can decide for themselves what information they want to transmit at factory level,” emphasises Cédric Berger.

New motor spindles

Up to 40% shorter cycle times are possible. It should be noted that Bumotec has replaced its 8,000rpm motor spindles with 25,000rpm models. “We developed the new motor spindles internally at a Starrag Group site,” emphasises Sylvain Bapst. What’s more, these new motor spindles with direct drive require less maintenance thanks to the high-pressure internal cooling of the tool, which operates at 70 bar. The motor spindles are equipped with acceleration sensors to monitor their vibration patterns. This allows the user of the Bumotec 1000/Cneo to check the condition of the spindles and also enables the control system (NC) to optimise the cutting conditions. To shorten the cycle times, a pick-up arm was added that has vices with a shorter stroke. The time for a parting-off sequence is now specified as 7 seconds, a reduction of 30%. The machining time is now 10 seconds – 51% less compared to the Bumotec s1000/C model.

Tool rupture can now also be detected via the machine’s software. For this purpose, a so-called ‘learning curve’ for the current consumption of the spindle was created using a machining sequence. If there is a deviation, a warning is issued.

Linear guides in the X, Y and Z axes

To improve the accuracy of the new horizontal transfer machine, the rigidity of the machining stations has been increased in the X, Y and Z directions. To achieve this, Bumotec no longer works with dovetail joints, but instead uses linear guides with slides, as Sylvain Bapst emphasises: “With the aim of maintaining the same rigidity, we carried out simulations in the workshop and confirmed them with measurements. As a result, we realised that we had not only increased the rigidity, but also reduced the friction so that we could move faster on the axes. So you could say that we have managed to achieve the same precision as a machine with just one rod.”

To unload the finished parts, Bumotec has opted for a blowing system that transfers the part to a plastic cup without being knocked. The cup, which is mounted on a linear arm, is then placed on a belt.

Reduction of the energy footprint

Another highlight of the Bumotec 1000/Cneo is the monitoring of energy consumption. Thanks to the integrated sensors, the Bumotec 1000/Cneo can display relevant values for compressed air and power consumption on its 24-inch screen. And the temperature conditions, too. Cédric Berger explains: “To cool the cutting oil, cold water is fed into the machine, which is then heated and flows back into the company’s ice water network. So, we installed sensors at the inlet and outlet to obtain information about the machine’s heat consumption, i.e. the energy required to keep the machine at the right temperature.”

The WattPilote system also plays a role in the quality of the parts produced. “By gaining a better understanding of certain machine phenomena, we could increase production, but also improve the surface quality of the workpiece,” explains Sébastien Campalto, application engineer at Bumotec. He continues: “WattPilote is a small oscilloscope that measures the power consumption and creates a curve while the tool is machining the workpiece. This means the operator knows in real time whether the machine is working properly or not.”

Costs reduced by 30%

The new HMI also offers various operating modes in accordance with ISO 14955: ‘OFF’, ‘STANDBY’, ‘READY’, ‘HEATING’ and ‘PRODUCTION’. “In particular, the operator can switch more easily from one operating mode to another. When production is finished. For example, the operator can choose whether their machine returns to Standby mode, where practically everything is switched off, or the machine returns to Heating mode because a new production run is about to follow. If production has still not started after one hour in Heating mode, the machine switches back to Standby. Everything is well thought-out and designed so that the customer can save energy,” says Cédric Berger.

Bumotec has successfully optimised all aspects of the energy required to operate the Bumotec 1000/Cneo. Total consumption has been reduced by 30%, compressed air consumption by 52%, saving up to 2kWh of electricity. The machine now requires only 245 litres of air, just 6 litres of hydraulic oil and 600 litres of cutting oil to operate. Depending on the workpiece and production conditions, the costs in watt hours per workpiece have been reduced by 30%. This corresponds to a production efficiency of over 98.3% and a reduction from 0.177kWh to 0.136kWh.

Finally, and this should not be underestimated, the footprint of the Bumotec 1000/Cneo has been reduced by 29%. The various functions and peripherals have been developed to minimise the space required. With a length of 6,445mm, a width of 4,950mm and a height of 3,251mm, the new Bumotec transfer centre takes up less than 32m² in the workshop.

Watchstraps: Bumotec cuts times in half

The new Bumotec 1000/Cneo has now been in operation for several months at a company that manufactures watchstrap parts. According to initial feedback, the manufacturer’s expectations were exceeded. “The increase in productivity is between 40 and 50% compared to the same workpiece machined on the Bumotec s1000/C. The customer was able to go from one minute to 30 seconds,” confirms Sébastien Campalto, application engineer at Bumotec.