Investing in new machine tools is always a major decision for any precision engineering company, especially when it involves a brand that’s unfamiliar in the market. That was the case for Genesis Precision in Cambridge, who recently took the plunge on a new turning centre supplied by Smartek, the UK distributor for Smart Machine Tools.

For Genesis Precision, ensuring machinery delivers both high accuracy and rock-solid reliability is key to maintaining its reputation. Like many engineering firms, Genesis had always stuck with trusted brands, but ongoing issues with older lathes pushed them to explore alternatives.

“We were facing costly repairs on our existing lathes when Kevin Wright told us about the Smart machines,” says Paul Barlow, Genesis’ owner and managing director. Kevin and his partner Bobby Graham—both with decades of machine tool servicing experience—recently became the UK agents for Smart Machine Tools, a Korean manufacturer launched in 2018 by former Samsung Machine Tools employees.

Genesis Precision, established in 2001, provides tight-tolerance milling and turning services for demanding industries including medical, high-tech, and scientific sectors. “Quality is everything for us,” Paul explains. “We need machines that can hit the finish and precision first time, every time.”

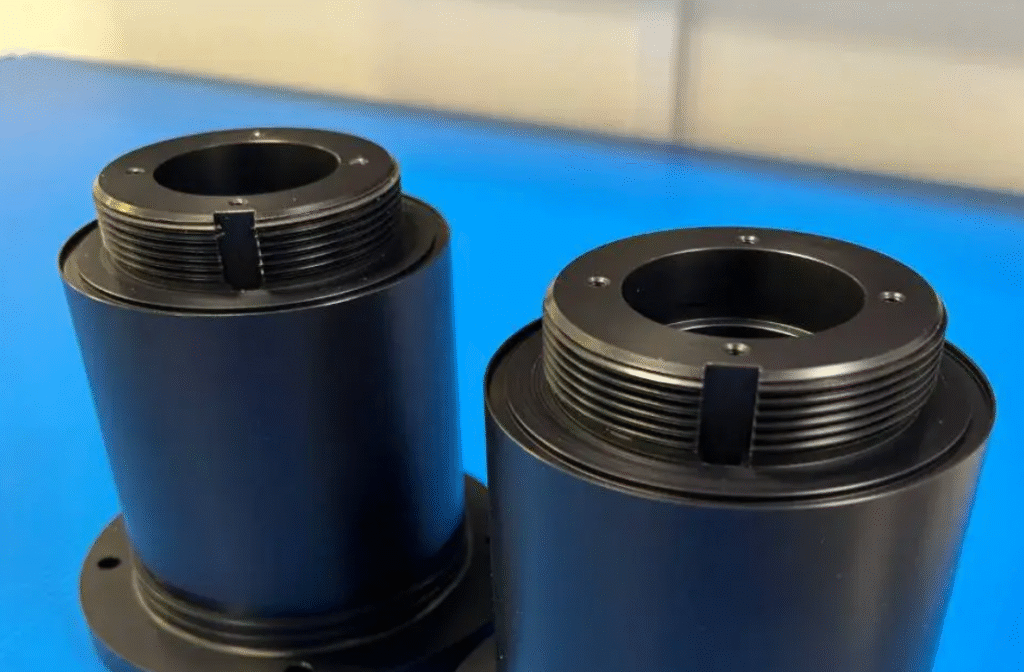

Genesis took delivery of a Smart NL 2000BSY turning centre featuring twin spindles, 8-inch chucks, a 4,500rpm spindle speed, and FANUC controls. It replaced a troublesome older machine and quickly proved its worth. “We’ve machined everything from plastics to stainless steel billets on it, and the results have been excellent,” Paul says. “It’s larger than our previous lathe, but it’s been trouble-free and the part finishes are consistently impressive.”

Genesis primarily machines aluminium, stainless steels, and high-performance plastics, with some heavier machining when required. Alongside its milling capabilities—including a YCM NXV 1020 VMC with robotic loading—the addition of the Smart turning centre has brought fresh capability and reliability to the business.

“After 12 months, the Smart lathe hasn’t had a single breakdown,” says Bobby Graham. “These machines are built for serious performance but at a much more affordable price point.”

Paul Barlow agrees: “I’d have no hesitation recommending Smart. It’s doing exactly what we need, without the hassle. That’s invaluable when you’re running a busy subcontracting business.”