Dalloway Engineering Celebrates 20 Years with Major Investment and Innovation

“There’s a lot of doom and gloom out there but, despite what you read, we’ve never been so busy,” says Joel Dalloway, workshop operations manager at Dalloway Engineering. As the precision engineering firm approaches its 20th anniversary, optimism is high. Over the next 12 months, the company plans to invest nearly £1 million in new equipment, expanded facilities, and additional staff to support its growing workload.

Dalloway Engineering has built a solid reputation over two decades by serving a diverse range of sectors, including food and beverage, rail, industrial applications, and more niche markets like sports medals and trophies. “We’re quite a mixed bag, but a lot of our work comes from referrals when people move roles,” explains Mr Dalloway.

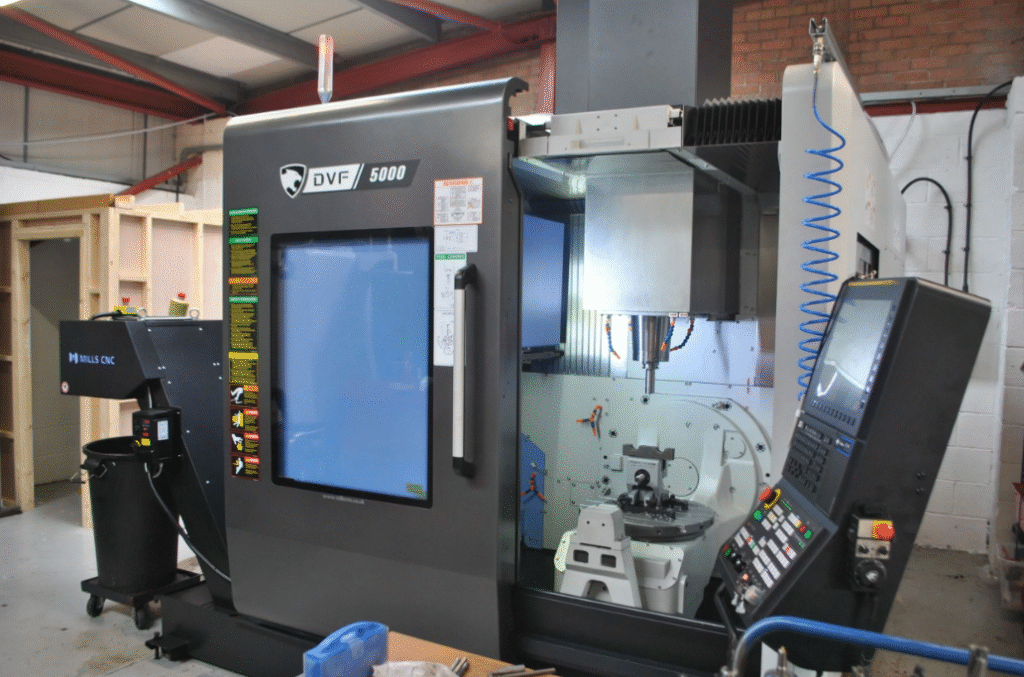

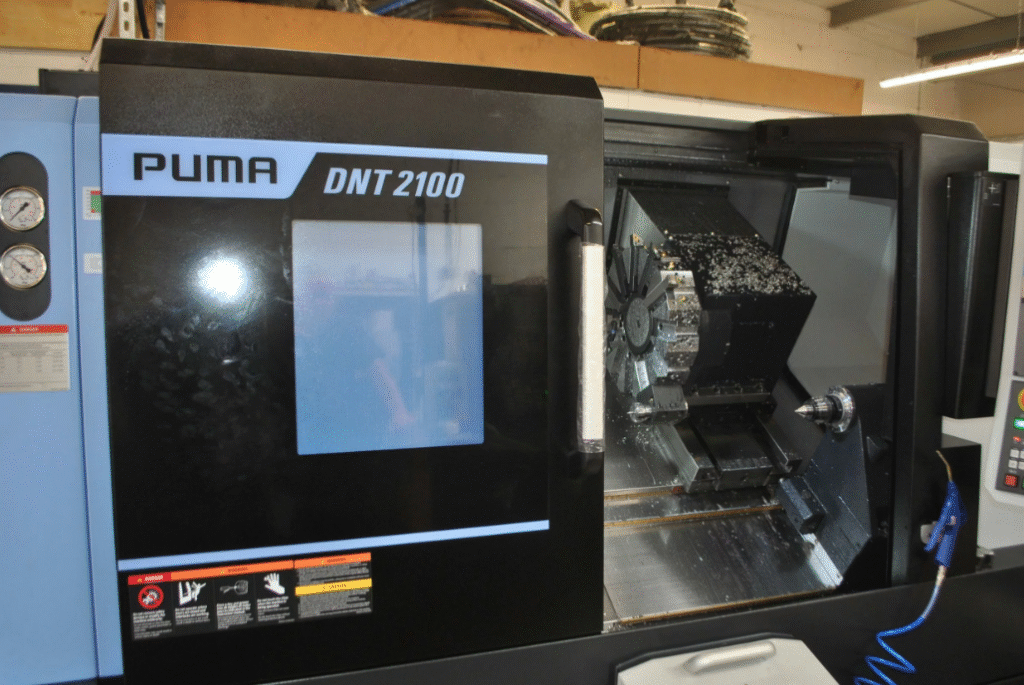

To meet rising demand, Dalloway is set to acquire a third industrial unit and invest in new machinery, including a machining centre and lathe from longtime partner Mills CNC. “Most of our machines are from Mills CNC. Consolidating with one supplier benefits us both — they understand our business, and we get better service and higher machining standards,” he notes.

Long-term partnerships are central to Dalloway’s success. Since its inception, the firm has collaborated closely with MSC Industrial Supply Co. UK, a trusted provider of metalworking, safety, and industrial consumables. “We buy almost everything from MSC — cutting tools, MRO supplies, health and safety equipment. Having one supplier makes my life easier,” says Mr Dalloway.

Recently, MSC’s introduction of its own-brand tooling, the MSC Edge range, has caught Dalloway’s attention. Launched in early 2025, this line of solid carbide holemaking and milling tools, covering diameters from 1mm to 20mm, has helped the firm dramatically reduce tooling costs while maintaining high performance.

“We’ve always cut a wide range of metals, from aluminium and brass to tough steels like stainless and 17-4 PH. I prefer top-quality tooling, but it’s expensive. Since switching to MSC Edge, our tooling costs have dropped significantly without sacrificing quality,” explains Mr Dalloway.

One standout project benefiting from the new tooling is an order to produce 120 display cases annually for some of the world’s most expensive whisky bottles, retailing for over £40,000 each. Initially taking 10 hours per case to machine on their Mills DVF-5000 5-axis machining centre, cycle times have been cut in half through optimized toolpaths and MSC Edge cutters.

“We buy 6m tubes, cut and face them on the lathe, polish, then mill the tapered helical slots with progressively smaller MSC Edge cutters, before a final polish and anodizing. The result is a stunning design destined for a famous London department store window,” says Mr Dalloway proudly.

Looking ahead, Dalloway is excited about the future: “With a great machine partner and now a great tooling partner, we’re definitely going places,” he concludes.