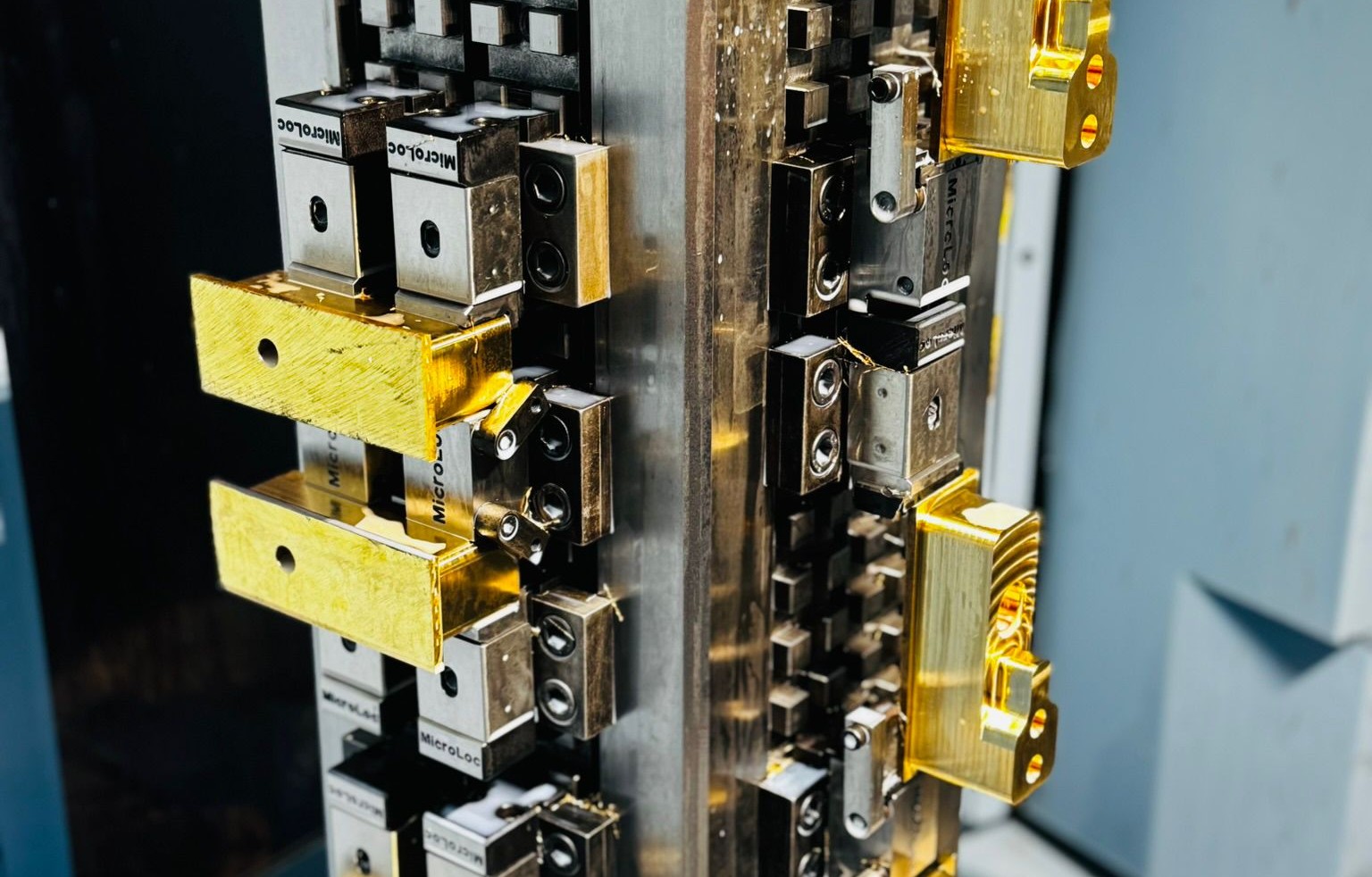

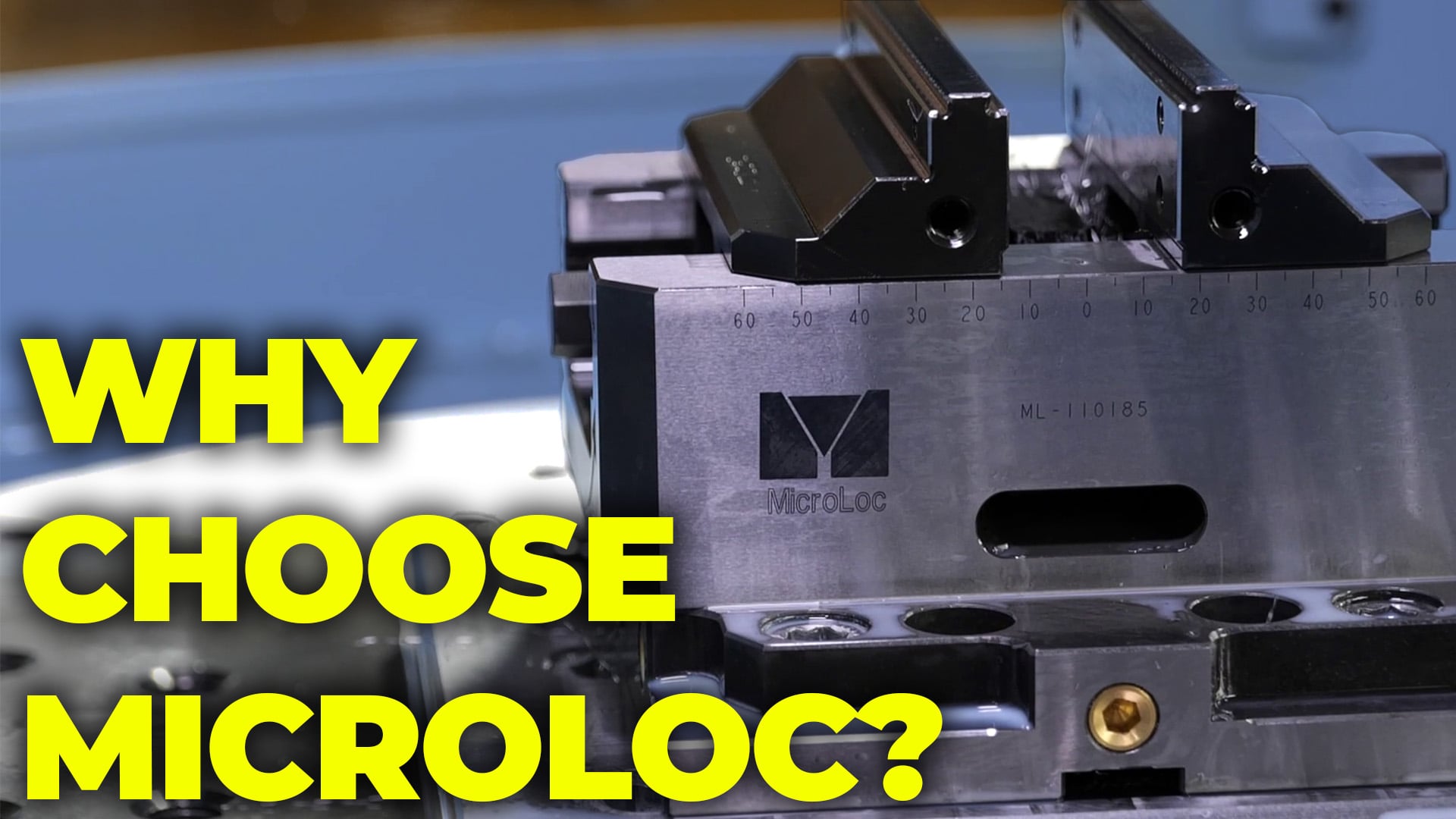

When it comes to getting the most out of your horizontal machining centre, few solutions match the versatility of MicroLoc Workholding’s cube fixturing system.

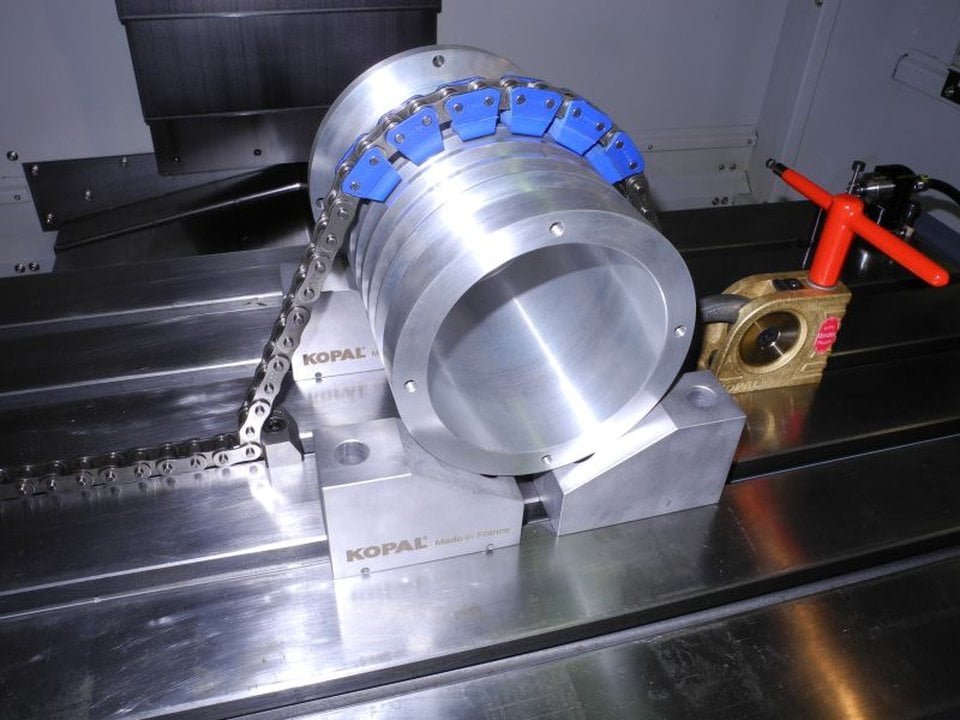

A firm favourite for Matsuura users, MicroLoc’s modular vices and clamping setups aren’t limited to just one brand. In fact, their adaptability makes them a brilliant fit for any horizontal machining setup, regardless of the manufacturer.

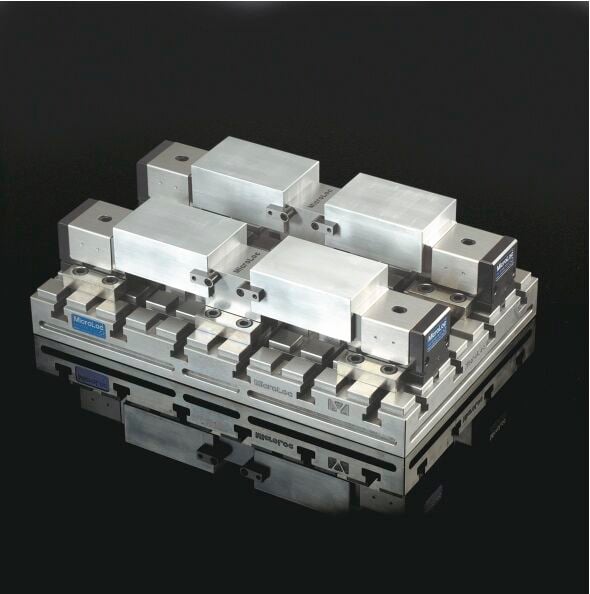

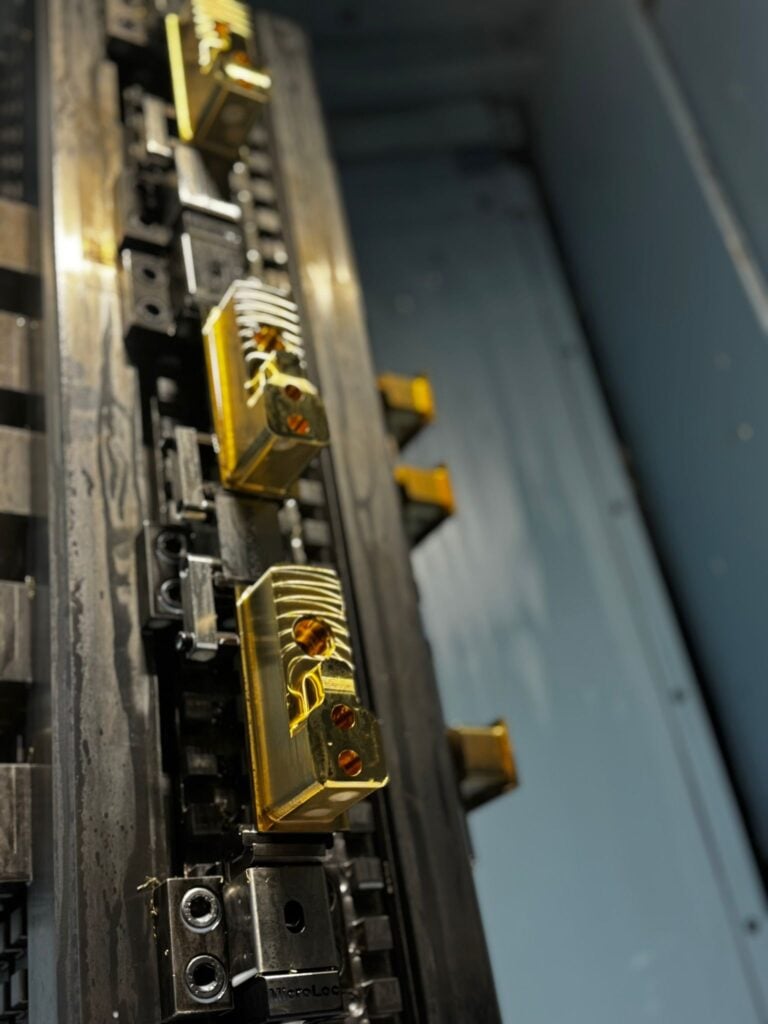

What makes this system stand out isn’t just how much you can fixture in a single cycle — it’s how flexible it is. While many think of cube fixturing for running multiples of the same part, MicroLoc goes much further. With their clever design, you can easily clamp different part types on different faces of the cube, reducing setups and keeping your spindles running longer.

The Benefits:

- Maximise your working envelope by using all four faces of the cube

- Reduce setup time with modular clamping options

- Run mixed batches without the hassle of constant changeovers

- Increase spindle uptime by loading once and machining more

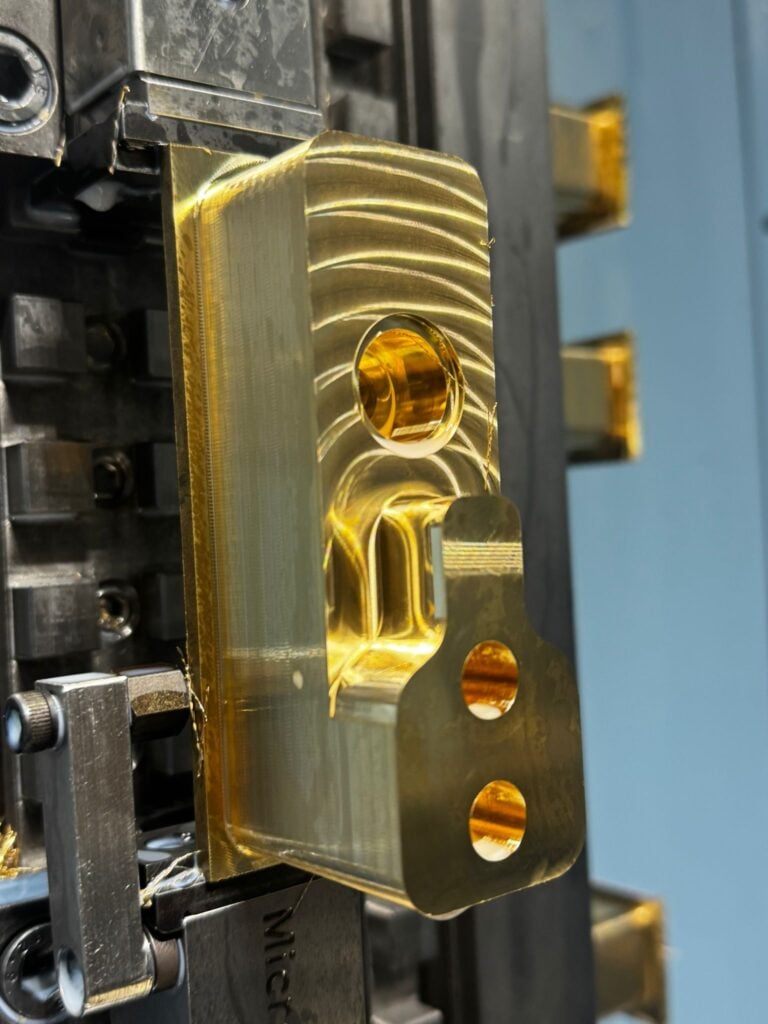

For manufacturers running high-mix, low-volume work or trying to squeeze the most productivity out of their machine time, MicroLoc delivers a practical, high-performance solution.

It’s not just about running big batches — it’s about smarter use of your machines, quicker turnarounds, and more parts off the machine, faster.

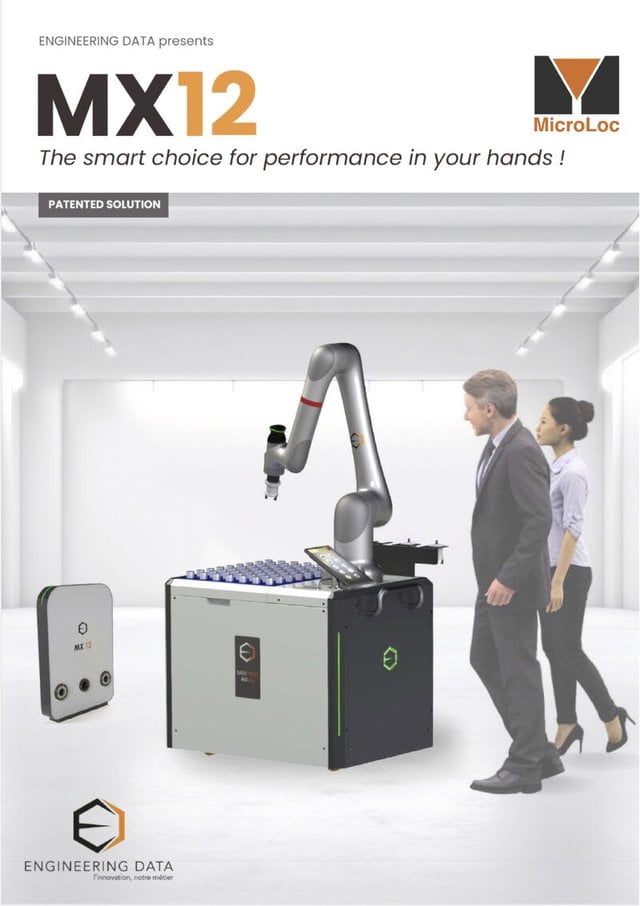

If you’re looking to improve throughput on your horizontals, MicroLoc’s fixturing system is well worth a closer look.