“We wanted the machine to be able to produce more or less all our parts that we have in the milling area here at Andritz.”

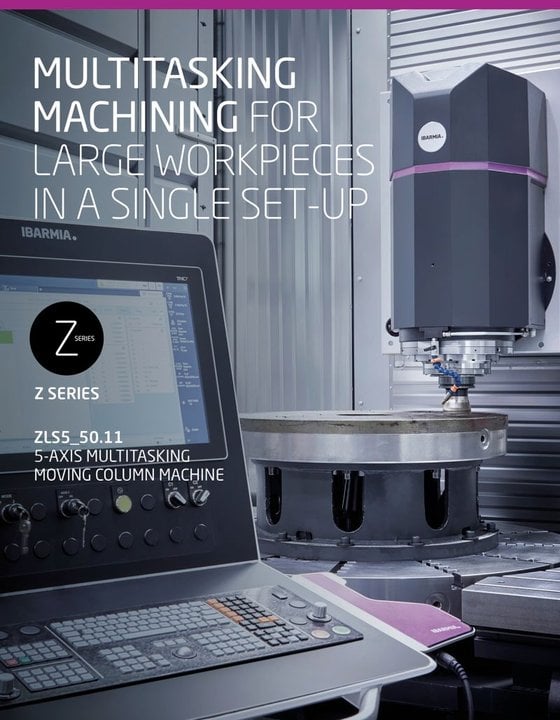

Partnering with Stenbergs, Andritz got a customised Ibarmia solution that delivers exactly that! By replacing three ageing machines with a single five-axis powerhouse, the team gained the strokes, swing, and ideal footprint they needed without compromising precision.

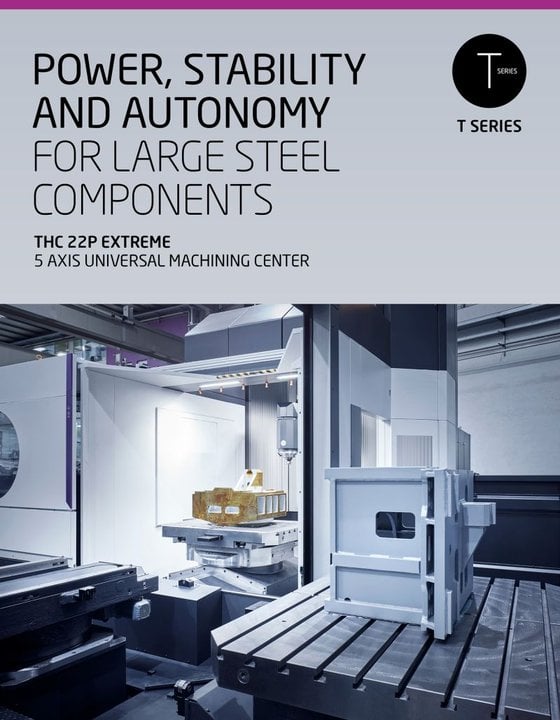

Faster cycles, dramatically reduced setups, and micron-level accuracy now define daily production at their facility in Iggesund. Tune in to hear more from Erik Molin, Hans Vedin, and Magnus Flemström of Andritz Pulp and Paper, and Gunnar Strömmer of Stenbergs as they break down how this customised Ibarmia THC-16 transformed their manufacturing.