ABC Compressors Future-Proofs Production with IBARMIA’s THC 16 MULTIPROCESS Technology

ABC Compressors, with over 80 years of heritage and a presence in more than 120 countries, continues to raise the bar in piston compressor manufacturing. Driven by a need to modernise and future-proof its operations in Eibar, Spain, the company has taken a major step by investing in IBARMIA’s THC 16 MULTIPROCESS machine with pallet pool automation.

This move reinforces ABC’s commitment to cutting-edge manufacturing technology, enabling higher flexibility, integration, and autonomy on the shop floor.

The Manufacturing Challenge

ABC Compressors faced growing pressure to manage shorter lead times, smaller batch sizes, and increased part complexity. Their aim was clear: reduce manual handling and setups, increase machining efficiency, and enable 24/7 operation — including one fully unmanned shift.

After evaluating several options, the company’s technical team selected IBARMIA’s THC 16 MULTIPROCESS, a solution capable of combining turning, drilling, and 5-axis milling in a single, fully integrated machine.

The IBARMIA Solution: THC 16 MULTIPROCESS

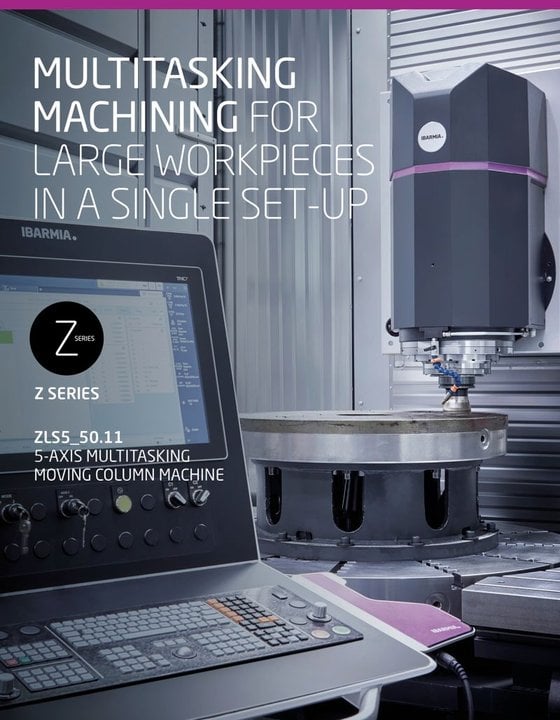

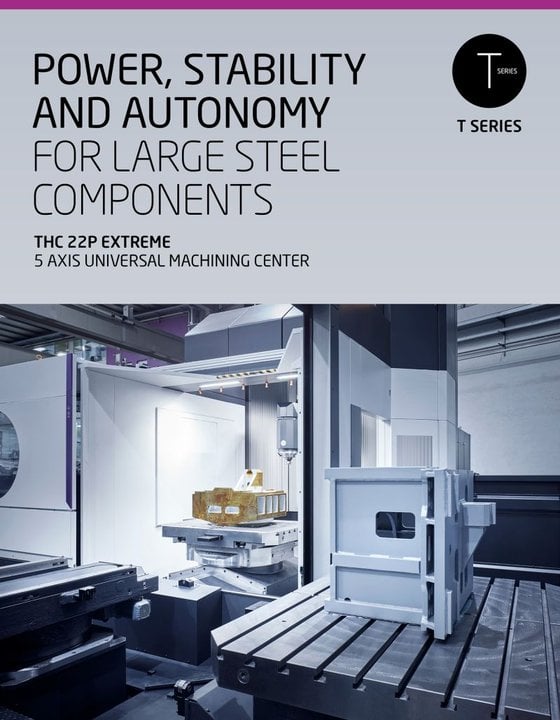

IBARMIA’s T Series is designed for high-complexity, multi-operation machining. The THC 16 MULTIPROCESS model selected by ABC offers:

- A travelling column and rotary transfer table for maximum accessibility

- Full MULTIPROCESS capabilities for combining operations in a single setup

- A robotised tool and head changer with up to 450 tool stations (HSK100 or CAPTO C6)

- Advanced sensor-based monitoring for tool wear, breakage, and management

- Integrated pallet pool system for unattended operation

This configuration delivers a fully automated workflow that boosts productivity while reducing downtime and operator intervention.

Smart Manufacturing with SMART POINT

The machine is equipped with SMART POINT, IBARMIA’s digital intelligence platform, allowing ABC to monitor real-time machining performance, tool use, and part status. This connected system provides actionable insights for continuous process optimisation — a key part of ABC’s smart manufacturing strategy.

A Collaborative Partnership

From specification to installation, the project was defined by close collaboration. ABC’s team, including Gaizka Oyarbide, Aitor Larruskain, and Aiert Gurrutxaga, praised IBARMIA’s support across commercial, mechanical, and electrical teams:

“The installation was smooth, and we adapted to evolving needs with minimal impact. IBARMIA’s flexibility and technical support made a real difference.”

Looking Ahead

With the THC 16 MULTIPROCESS now fully operational, ABC Compressors has enhanced its agility, efficiency, and competitiveness — not just for today’s demands, but for the future of global manufacturing.

The investment reflects a shared vision between ABC and IBARMIA: a future where precision, automation, and intelligence drive sustainable production forward.