Building off the success of our first 5-axis CNC our next four to five machines will be 5-axis CNCs

Qualitex, Inc., located in Columbia City, IN, is a full-service gauge and fixture manufacturer that specializes in inspection services, gauges, fixtures and tooling. Founded in 1993 by Rick Williams, Qualitex has grown from a small shop to a company with over 20 employees and 30 machines housed in a 16,000 sq. ft. facility. The company is ISO 9001:2015 certified and holds ISO/ IEC 17025 accreditation.

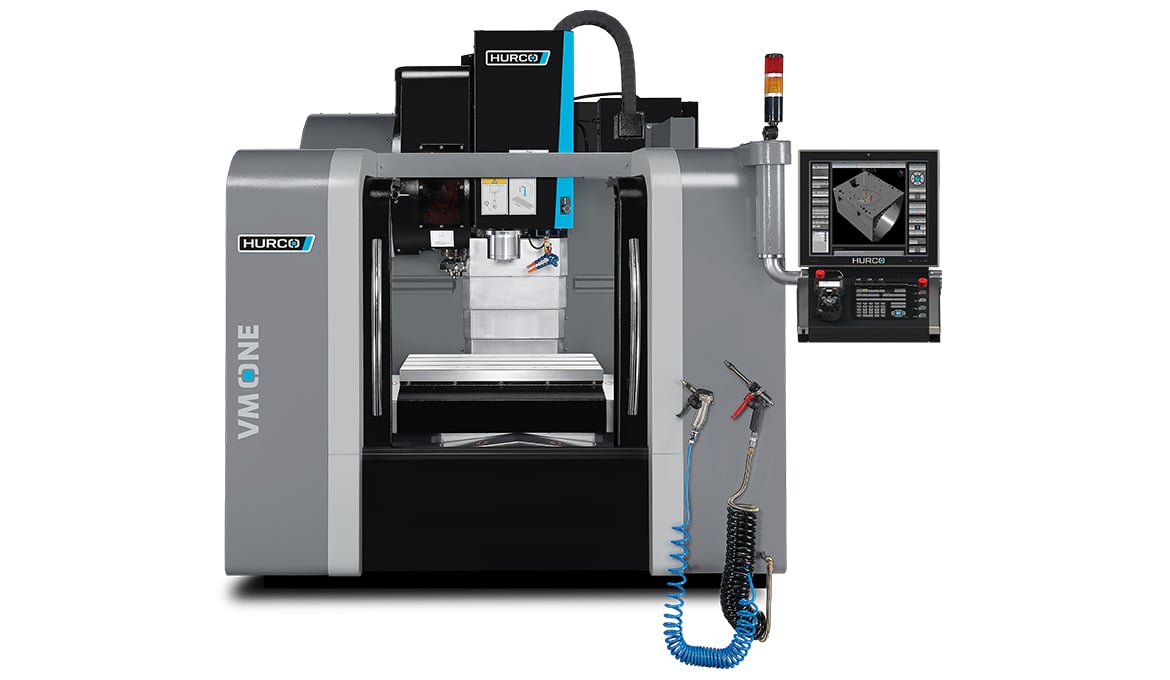

Qualitex customers are some of the largest companies in the world and include Tier 1, Tier 2 and Tier 3 OEMs that serve primarily the automotive industry and orthopedic sector in the medical industry. These industries largely deal with tool steel and tight tolerances. Qualitex currently has nine Hurco CNC machines, with the latest purchase being a Hurco 5-axis VMX42SRTi that has taken Qualitex to “a whole new level,” according to owner Rick Williams.

Williams began his career path in high school at an automotive metal stamping facility running punch presses. After graduation, he transferred into the quality department where he learned customized programming and how to run CMMs. While attending college, Williams continued working and was promoted to quality engineer and eventually quality manager, overseeing a tool and die facility of over 80 employees. He worked directly with OEMs, such as Chrysler, GM, Toyota and Ford, on die runoffs and gauge programs. This led to Williams being responsible for all gauge quoting and design/build activities for the company.

Williams then ventured out and started his own CMM inspection/gauge and fixture company in 1993. When asked why he chose Hurco CNC machines when he started his new business, he identified three primary reasons:

• The fast return on investment (ROI) of Hurco CNC machines

• The ability to close the skills gap due to Hurco’s conversational programming control feature

• The experience he had with Hurco CNC machines when he worked for the aforementioned tool and die facility.