Lyndsey talks to MD Daimon Wellington about their HURCO VC500i investment

By Lyndsey Vickers

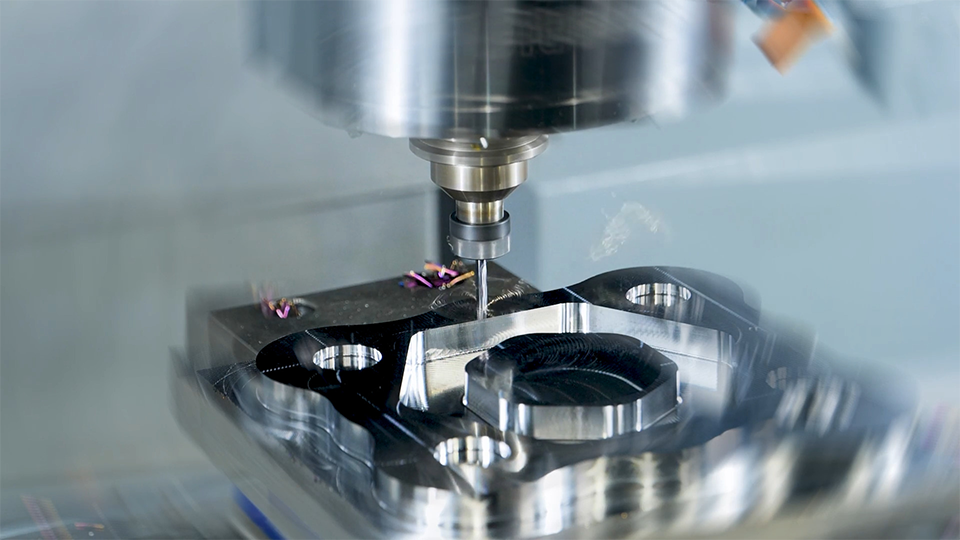

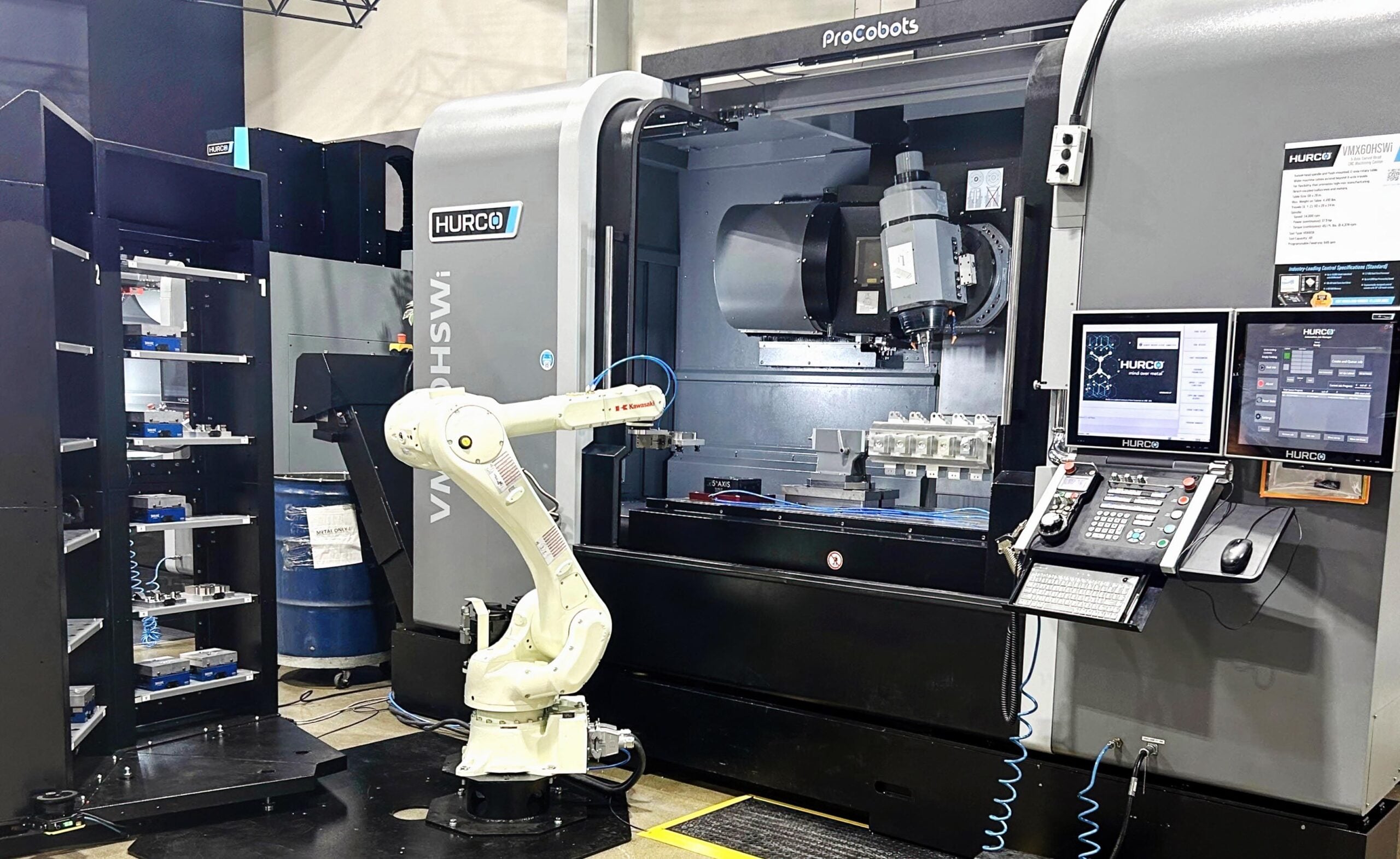

Daimon Wellington, Managing Director of Wellington Engineering, shares his perspective on their latest investment in the HURCO VC500i, a 5-axis Cantilever machining center. Productivity is the key driver for Wellington Engineering, and with new complex odd-shaped parts coming in, they needed the right support and technology to get jobs out the door faster. The VC500i is ergonomically designed for easy access and perfect for hitting all faces in one setup, significantly reducing the number of operations. The new investment allowed Wellington Engineering to get jobs done more efficiently without taking up extra manpower or capacity from other machines. Using machine efficiency software, Wellington Engineering are able to quantify their success by monitoring run times and cycle times. Find out more from Daimon on machine efficiency, manufacturing output, and excellent feedback from customers for jobs completed on this incredible HURCO machine.

[ID3964223582]