Keeping Production Lines Moving: The Toolroom Ltd and Hurco Europe

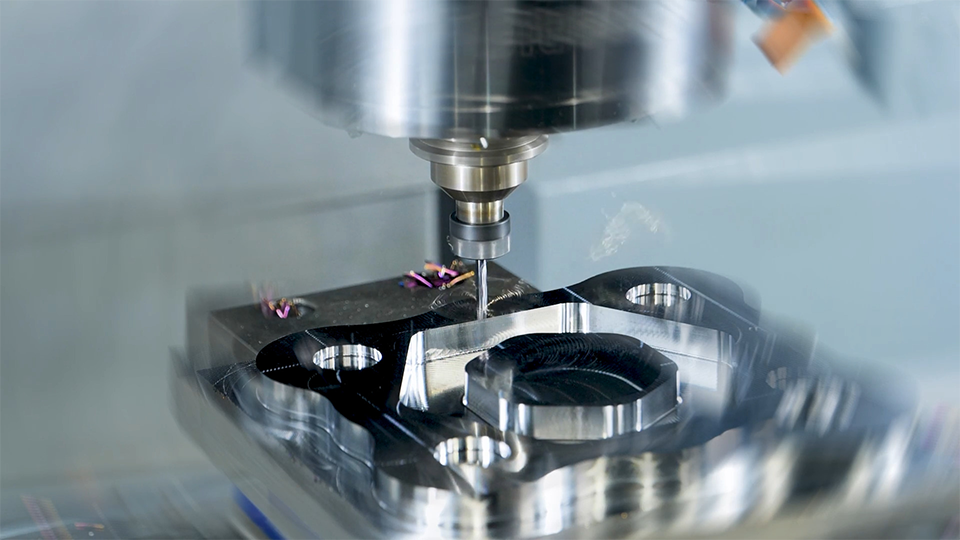

When it comes to keeping critical production lines moving across the UK, The Toolroom Ltd is a name that stands out, the company specialises in precision engineering, batch work, and the reverse engineering of components for manufacturing and industrial customers. Their expertise allows them to tackle projects where parts arrive without drawings and need to be recreated to exact specification in a matter of days.

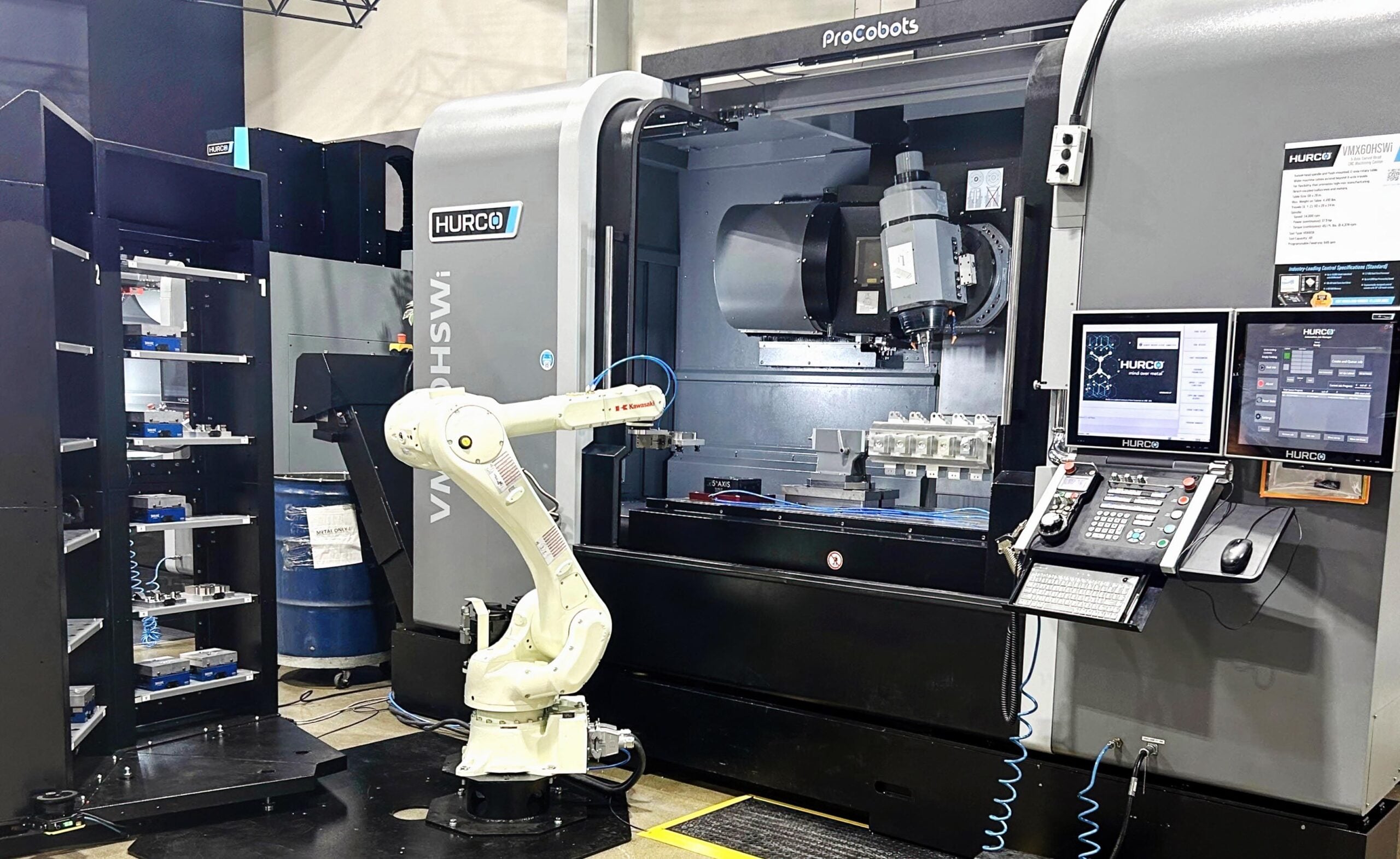

At the heart of their operations is a six-machine fleet of Hurco machinery, providing the flexibility, speed, and reliability that modern manufacturing demands. Whether it’s high-precision batch production, prototype work, or re-manufacturing vital components for production lines, these machines allow The Toolroom Ltd to maintain quick turnaround times and consistent quality, even for blue-chip clients operating under tight deadlines.

Jeff Storey from The Toolroom Ltd explained that the ease of use and dependability of their Hurco machines is a key factor in their success. The intuitive controls and robust build quality mean their team can focus on problem-solving and delivering results, rather than troubleshooting machine issues.

The company’s work spans multiple industries, from automotive and aerospace to general manufacturing, showing how skilled engineering combined with the right technology can keep production lines running smoothly across the country.

MTDCNC had the pleasure of visiting the team, where we were welcomed by Jeff Storey, Ray Liddell, and the rest of the team. Their dedication, technical expertise, and efficient workflow were truly impressive—and a clear example of how Hurco Europe machinery is helping UK manufacturers stay productive, flexible, and competitive.