Nothing to see here… just Red Bull’s incredible Technology Campus in Milton Keynes, Buckinghamshire!

Earlier this week, the MTDCNC team had the privilege of visiting one of the UK’s most advanced engineering facilities – the Red Bull Racing Technology Campus in Milton Keynes – for the Hexagon Manufacturing Intelligence Aerospace Innovation Event.

This unique event brought together leaders in aerospace, motorsport, and advanced manufacturing to showcase the latest developments in metrology, simulation, digital twins, and smart manufacturing technologies. The combination of Red Bull’s world-class environment and Hexagon’s digital innovation made for an inspiring day that highlighted how precision engineering is shaping the future.

Red Bull’s Technology Campus – A World-Class Facility

Walking through the doors at Red Bull Racing’s headquarters, it’s impossible not to be impressed. This is the home of multiple Formula 1 world championships – a place where engineering excellence, speed, and precision are woven into the fabric of daily work. Every detail, from design and prototyping to testing and production, reflects a relentless pursuit of performance.

The Technology Campus is not just a base for Red Bull Racing; it is a hub of cutting-edge research and development, making it the perfect venue to host a forward-looking event on aerospace and manufacturing innovation.

Hexagon – Building the Future of Aerospace Manufacturing

At the heart of the event was Hexagon Manufacturing Intelligence, a global leader in advanced manufacturing technologies. The focus was on how Hexagon is enabling aerospace companies to reduce risk, accelerate production, and achieve higher levels of accuracy and efficiency.

Key themes included:

- Metrology Excellence: Demonstrations showed how Hexagon’s precision measurement tools are capable of capturing the finest tolerances, ensuring aerospace components meet exacting standards.

- Simulation Capabilities: By validating designs digitally before production, Hexagon helps manufacturers cut costs, shorten lead times, and improve performance.

- Digital Twin Technology: Hexagon showcased how real-time digital replicas of products and processes can be used to monitor, optimise, and continuously improve aerospace operations.

- Smart Manufacturing: By connecting data across the entire value chain – from design to final inspection – Hexagon is helping companies unlock new efficiencies and insights.

These aren’t concepts for the distant future. As Hexagon demonstrated throughout the day, these tools are available today, driving transformation in aerospace and beyond.

Inspiration from Motorsport to Aerospace

Holding the event at Red Bull Racing’s Technology Campus underscored an important message: whether in Formula 1 or aerospace, precision, performance, and speed-to-market are everything. Motorsport and aerospace share common challenges – complex parts, tight tolerances, and the need to innovate constantly – and both industries benefit from Hexagon’s digital-first approach to manufacturing.

The event also highlighted how digitalisation and data-driven decision-making are becoming central to competitiveness. For aerospace manufacturers, adopting these tools is no longer optional – it’s the key to thriving in a market that demands both reliability and agility.

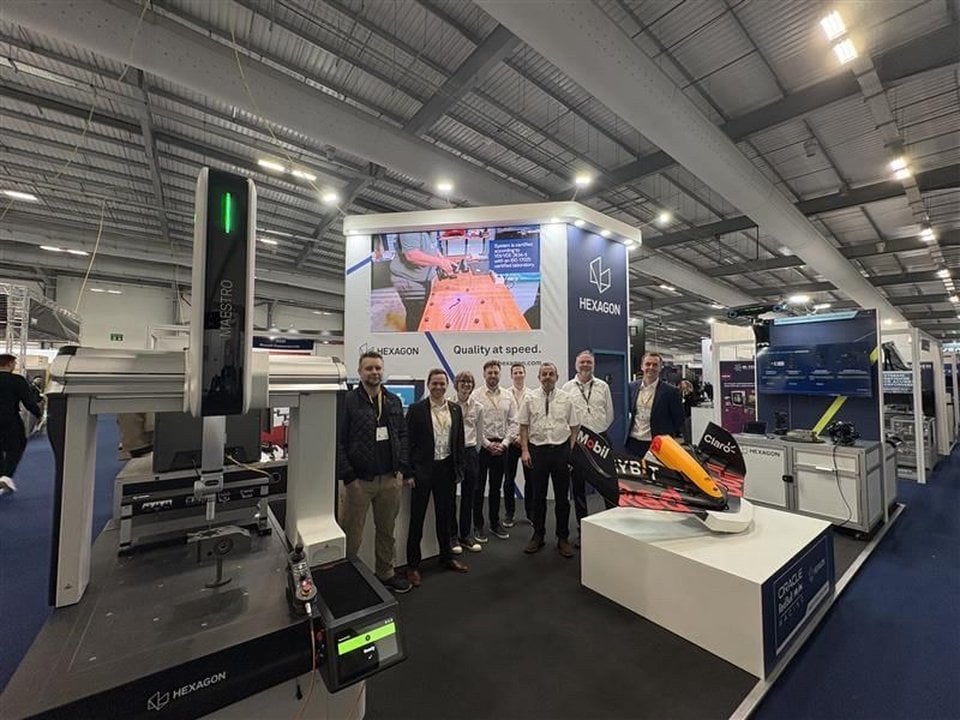

MTDCNC at the Event

Our team – including Tom Skubala, Karl Creamer, Rhys Williams, Rowan Easter-Robinson, Joe Amos, and Elliott Wright – were on-site to capture the technology, the stories, and the people behind the innovation. From interviews with Hexagon’s experts to a behind-the-scenes look at the demonstrations, we’ve recorded the highlights to share with our audience.

Looking Ahead

The Hexagon Aerospace Innovation Event was more than just a showcase – it was a clear statement of how manufacturing is evolving. By combining cutting-edge measurement, simulation, and digital twin technologies, Hexagon is helping industries achieve the precision, productivity, and performance needed for the future.

And by hosting it at Red Bull Racing’s Technology Campus, the event also reminded us that the worlds of motorsport and aerospace are deeply connected – both striving to push the boundaries of what’s possible through engineering excellence.

🎥 MTDCNC has captured it all, and we’ll be sharing the videos very soon. Stay tuned for exclusive content from inside Red Bull’s campus and Hexagon’s Aerospace Innovation Event.