Historically, a majority of subcontractor Reginson Engineering’s turnover came from the aerospace sector, with oil and gas generating most of the remainder. So, when Covid struck in early 2020 and aerospace contracts dried up, the Nuneaton-based, AS9100 accredited, Rolls-Royce approved company was deeply affected by the contraction in business.

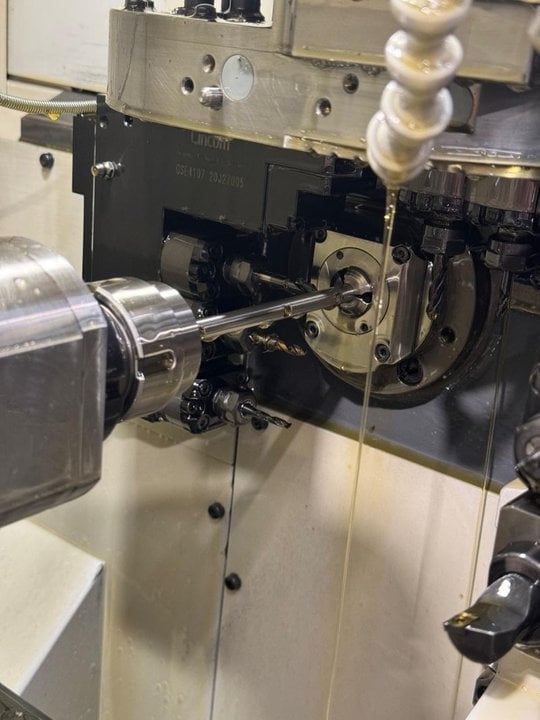

It was mitigated somewhat by the company joining the Ventilator Challenge UK. During April 2020, Rolls-Royce asked Reginson Engineering to manufacture 113,000 components in 10 days to support the build of 8,000 ventilators. Towards the end of that month, within 36 hours of an order being placed for a pair of Cincom A20-VIIs sliding-head CNC turning centres to enable the medical contract to be fulfilled, the machines were delivered by Citizen Machinery UK. Both have LFV (low frequency vibration) chip-breaking capability, which not only improved swarf control, raising reliability and reducing the need for operator intervention, but also enhanced the surface finish on components.

The medical work was only temporary, however, so the family-run business owned by Steve Hatch set about finding business elsewhere. What transpired altered the company’s fortunes entirely, as a contract from a jewellery manufacturer combined with strong growth in aerospace conspired to increase turnover so dramatically that by 2023 it was 447% higher than before the pandemic.

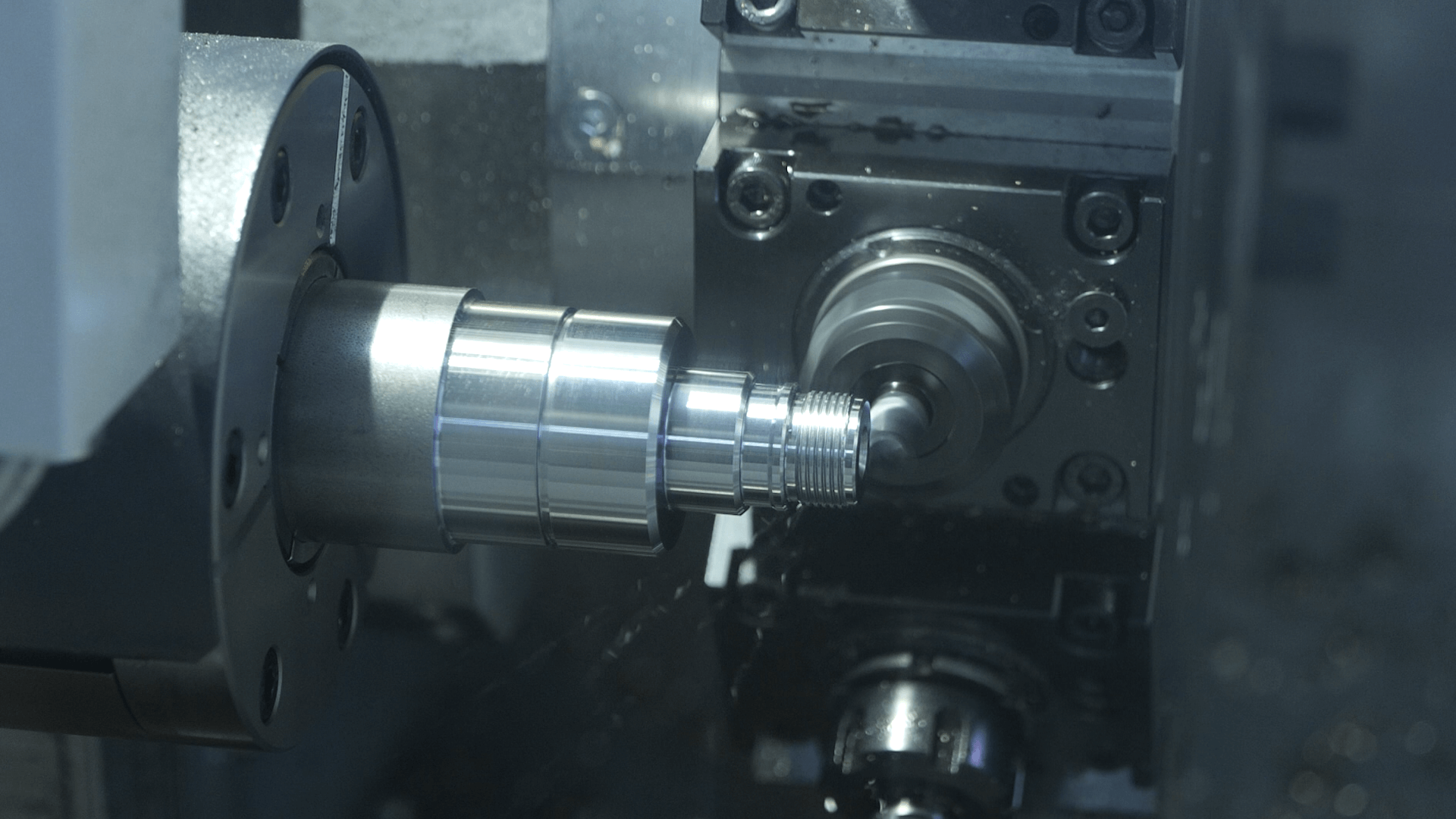

Even better is to come. The jewellery company is so pleased with the quality of the mainly titanium jewellery pieces already supplied that it has signalled its intention to increase the annual quantity of parts from 100,000 to 1 million per month over the next few years. The machine tools underpinning both the quantity and quality of the jewellery parts produced at the Nuneaton factory are yet more Citizen Cincom sliding-head lathes.

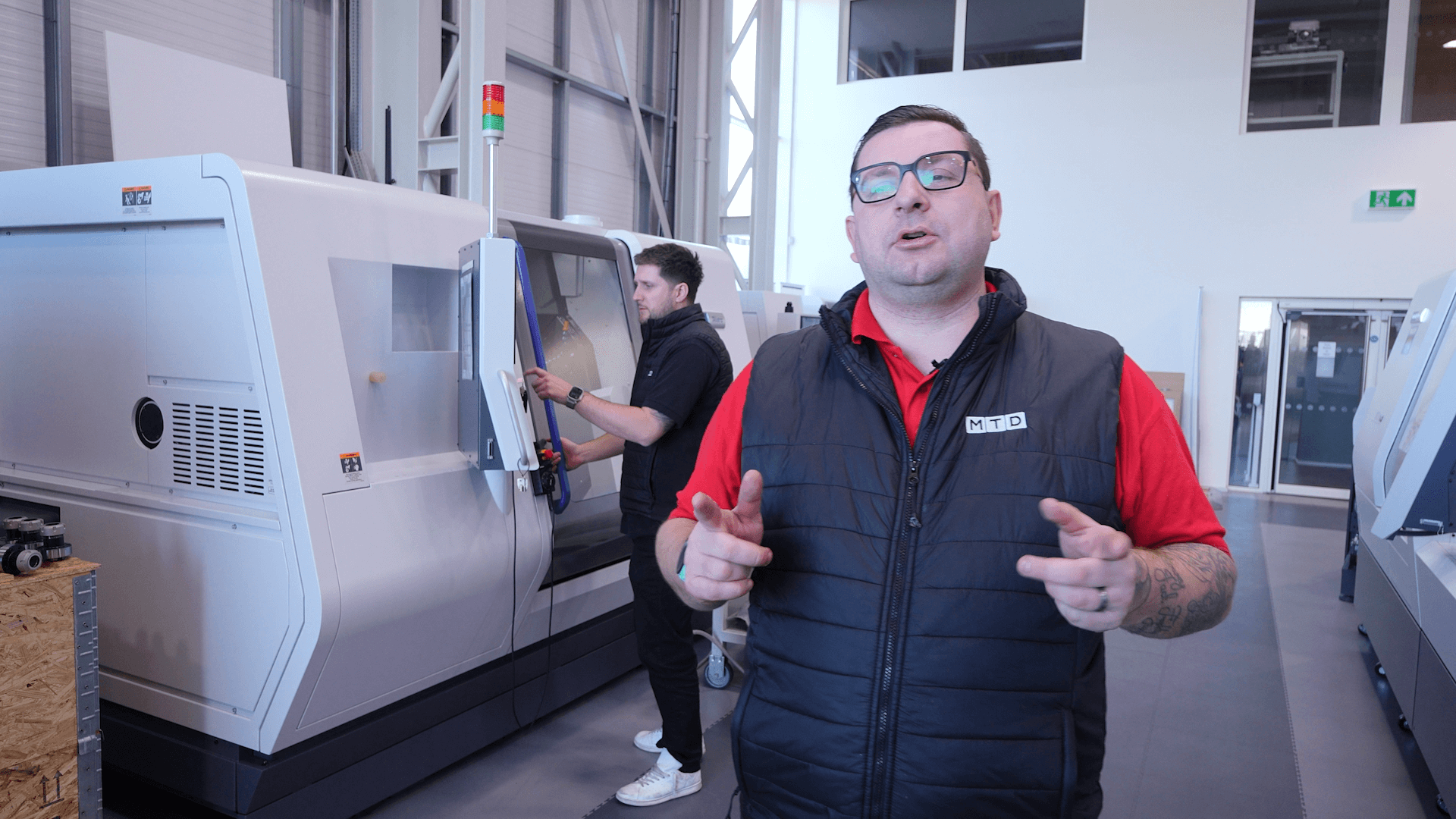

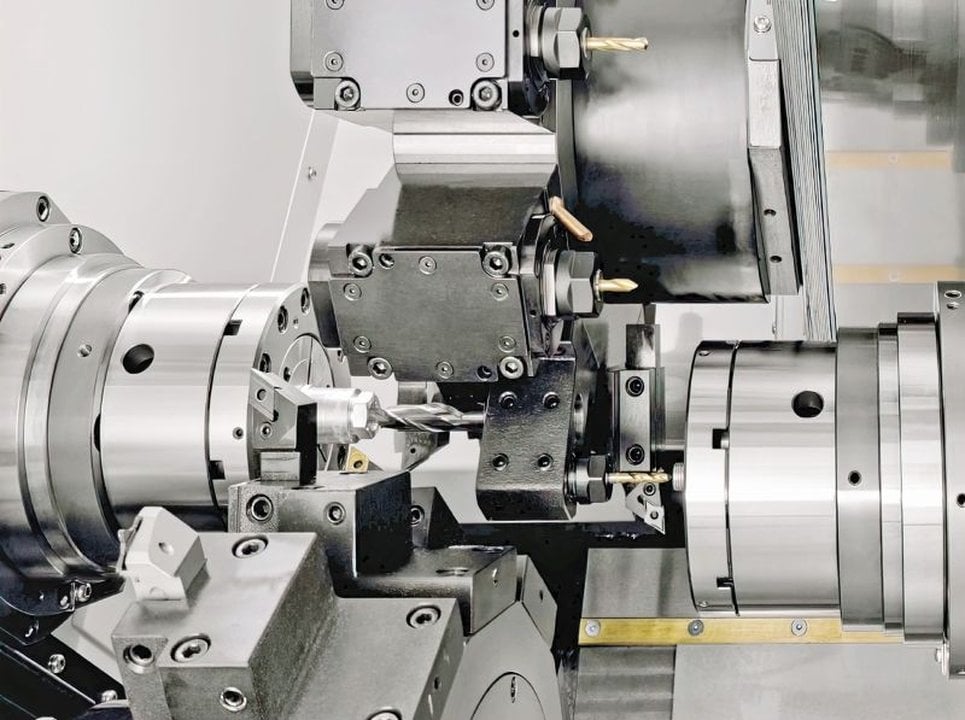

Reginson Engineering is a long-time user of these Japanese-built sliders dating back to the early 1990s. In October 2020, the lathes were joined on the shop floor by the subcontractor’s first Citizen fixed-head model, a 64 mm bar capacity Miyano ABX-64SYY twin-turret, twin-spindle turn-mill centre. The user describes the machine as being fantastic, as it has allowed cycle times to be slashed compared with using other turning plant on site. Shortly after its arrival, it more than halved the cycle time for producing a component from 4 minutes 30 seconds to 117 seconds complete.

The upturn in throughput generated by the jewellery contract required much more sliding-head capacity, so the subcontractor has bought 14 new Cincoms in the last couple of years. They are seven 20 mm bar capacity A20-VIIs and the same number of 12 mm capacity L12-VIIs. Twelve of them are devoted to jewellery component manufacture and the other two were acquired to boost production of smaller aerospace parts. The latest influx of new lathes plus the recent purchase of two new 5-axis machining centres brings the total number of CNC machines in the Nuneaton factory to nearly 100.

Machine shop manager and family member Tom Hatch said, “We chose twin-spindle sliders for the jewellery work because positioning cutters on gang toolposts for the next operation is much faster than indexing turrets in a fixed-head lathe. It means we can produce components more quickly, not only because there is less idle time, but also because there is more scope for reducing the number of second and subsequent operations.”

He added that the machines are easy to set and operate, to the extent that he and one other staff member run 12 Cincom’s located in an adjacent factory unit that has been leased recently for the new project. The finish of the turned surface achieved on the lathes is 0.2 µm, which lessens the amount of polishing that has to be done in Nuneaton or by the customer.

Similarly, the performance of the Cincoms when producing aerospace parts is excellent due to the extreme rigidity of the machines, despite having to cut materials ranging from tough nickel alloys to titanium and stainless steels. Tolerances down to ± 3 µm are often turned, saving the time and expense of grinding parts in another operation. Surface finish is also high at up to 0.8 µm when required.

Reginson Engineering additionally runs UPR, a subsidiary company in Pune, India, which it set up in 2014. The facility has more than 20 CNC machines and 60 employees, enabling the firm to offer low-cost components to customers worldwide, mainly in the aerospace, wind turbine, medical and oil and gas industries.